Efficient dissolved air flotation machine

A dissolved air flotation machine and air flotation technology, used in flotation water/sewage treatment, energy and wastewater treatment, etc., can solve the problem that the gas-liquid ratio cannot be automatically adjusted, the optimal gas-liquid ratio cannot be maintained, and the overall density of flocs can be reduced. and other problems to achieve the effect of reducing process links, improving water treatment effect and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

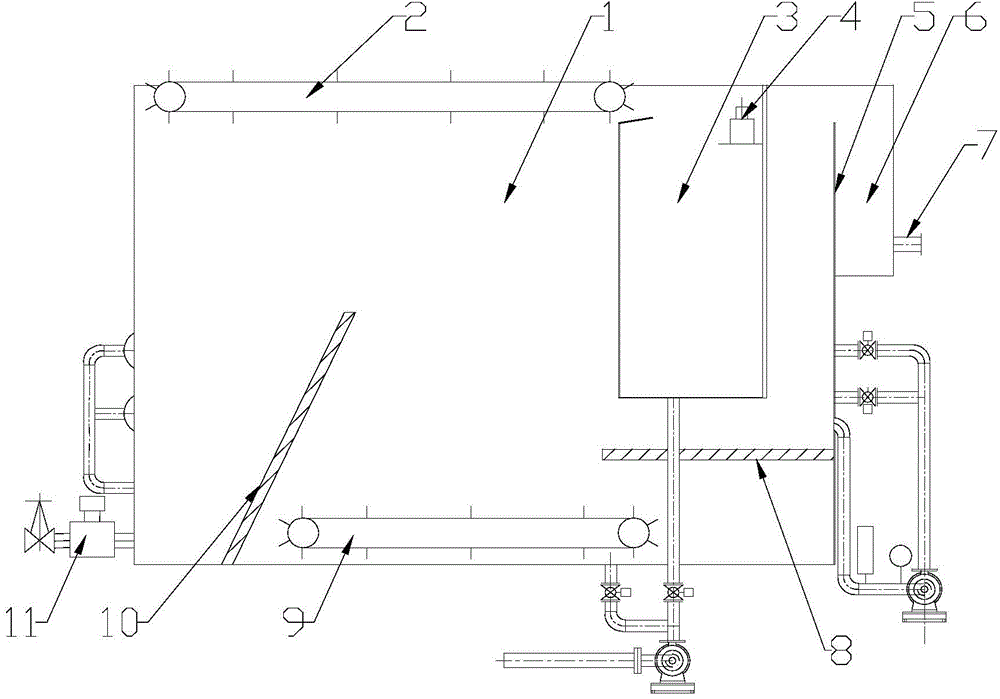

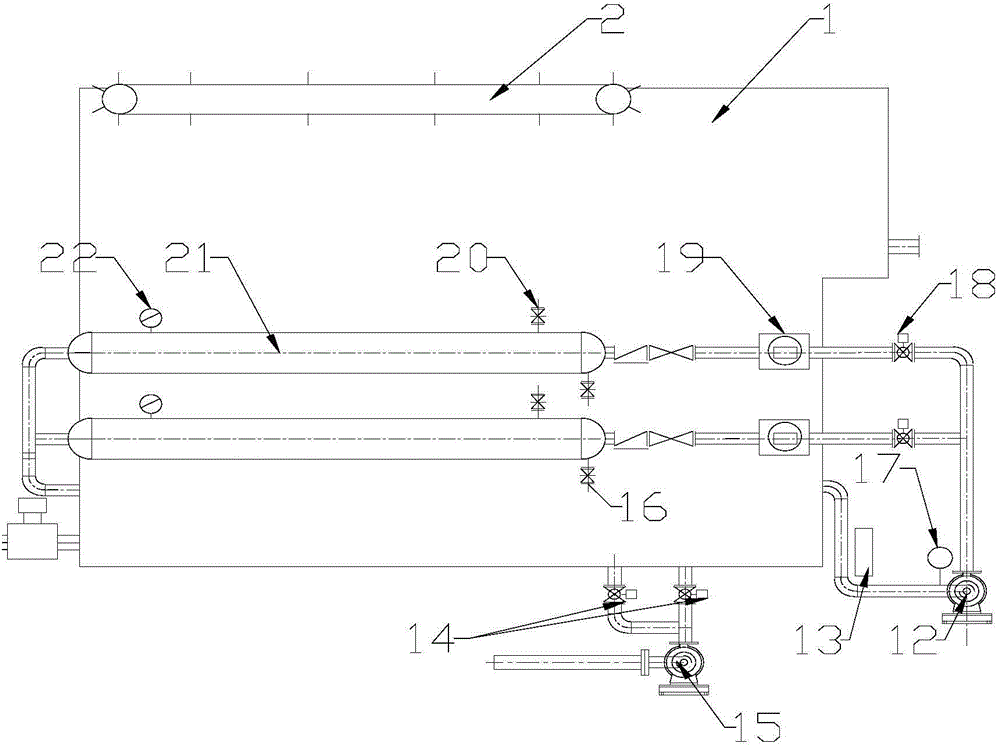

[0012] Depend on figure 1 combine figure 2 As shown, the high-efficiency dissolved air flotation machine includes an air flotation box 1, the air flotation box 1 is a square metal box with a bottom, and a release partition 10 is provided along the length direction of the air flotation box 1, and the release partition 10 is close to The water inlet flowmeter 11 connected to the water inlet, the release partition 10 is arranged obliquely so that a semi-enclosed space with a narrow bottom and a wide top is formed on the left side of the release partition 10, and an oil scraper 2 is installed on the upper part of the release partition 10, and the oil scraper 2 On the right side there is a bottomed semi-closed oil collection pool 3 surrounded by steel plates. The oil scraper 2 collects the oil and dirt floating in the air flotation box 1 into the oil collection pool 3. On the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com