Process for preparing ultrafine aluminum hydroxide by seed crystal precipitation method

A technology of ultra-fine aluminum hydroxide and aluminum hydroxide, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, can solve the problems of large gaps, non-universal production equipment and processes, and increased overall costs. Achieve the effect of low cost, excellent performance and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

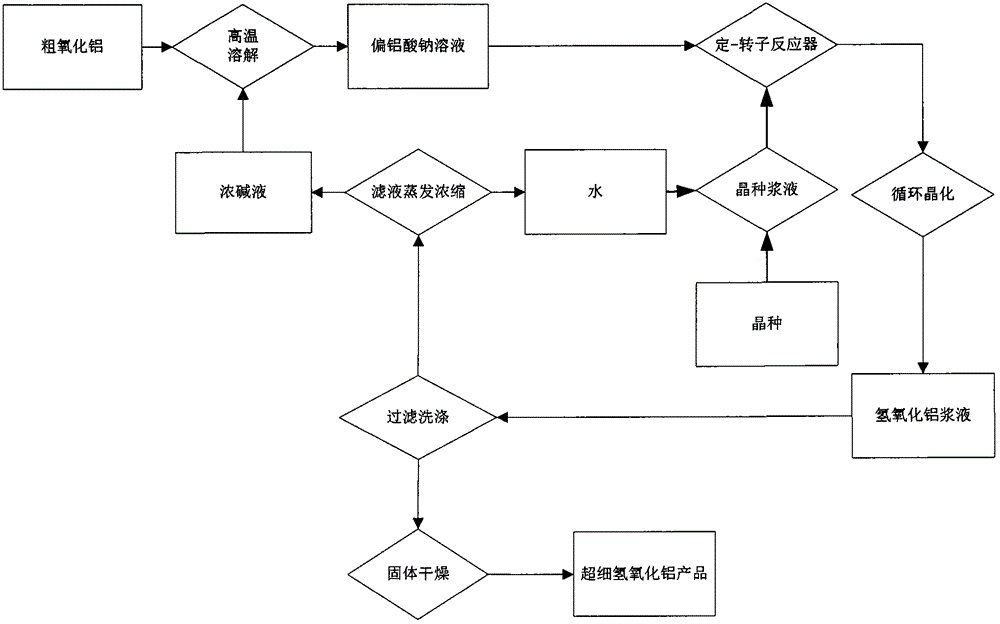

Method used

Image

Examples

Embodiment 1

[0031] At a temperature of 100°C, coarse alumina ore is dissolved in concentrated alkali solution with a mass concentration of 25% to prepare a concentrated metaaluminate saturated solution. The concentrated solution and distilled water were quickly mixed in a ratio of 3:1 in a stator-rotor reactor at a temperature of 40° C., and the stator-rotor speed was 300 rpm. The mixed reaction solution went through a crystallization process of 120 h under continuous stirring. The solid product obtained by filtering and separating the crystallized reaction liquid is washed with process water for 3 to 4 times, and dried at 100° C. for 24 hours to obtain crystal seeds for preparing ultrafine aluminum hydroxide. After the filtrate is evaporated to recover the process water, the concentrated liquid is redissolved and circulated.

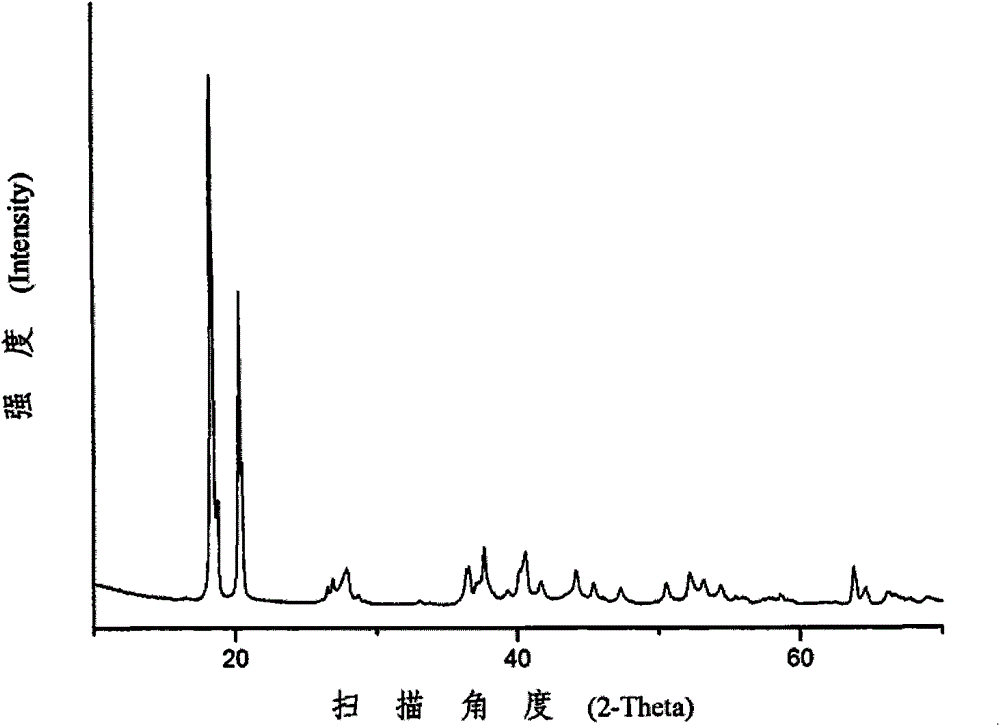

[0032] The obtained aluminum hydroxide seed crystals carry out XRD characterization, see specification attached figure 2 .

Embodiment 2

[0034] At a temperature of 200°C, coarse alumina ore is dissolved in concentrated alkali solution with a mass concentration of 40% to prepare a concentrated metaaluminate saturated solution. The concentrated solution and distilled water were quickly mixed at a ratio of 1:4 in a stator-rotor reactor at a temperature of 90° C., and the stator-rotor speed was 3000 rpm. The mixed reaction solution went through a crystallization process for 12 h under continuous stirring. The solid product obtained by filtering and separating the crystallized reaction liquid is washed 3 to 4 times with process water, and dried at 120° C. for 24 hours to obtain crystal seeds for preparing ultrafine aluminum hydroxide. After the filtrate is evaporated to recover the process water, the concentrated liquid is redissolved and circulated.

[0035] Preparation example of ultrafine aluminum hydroxide

Embodiment 3

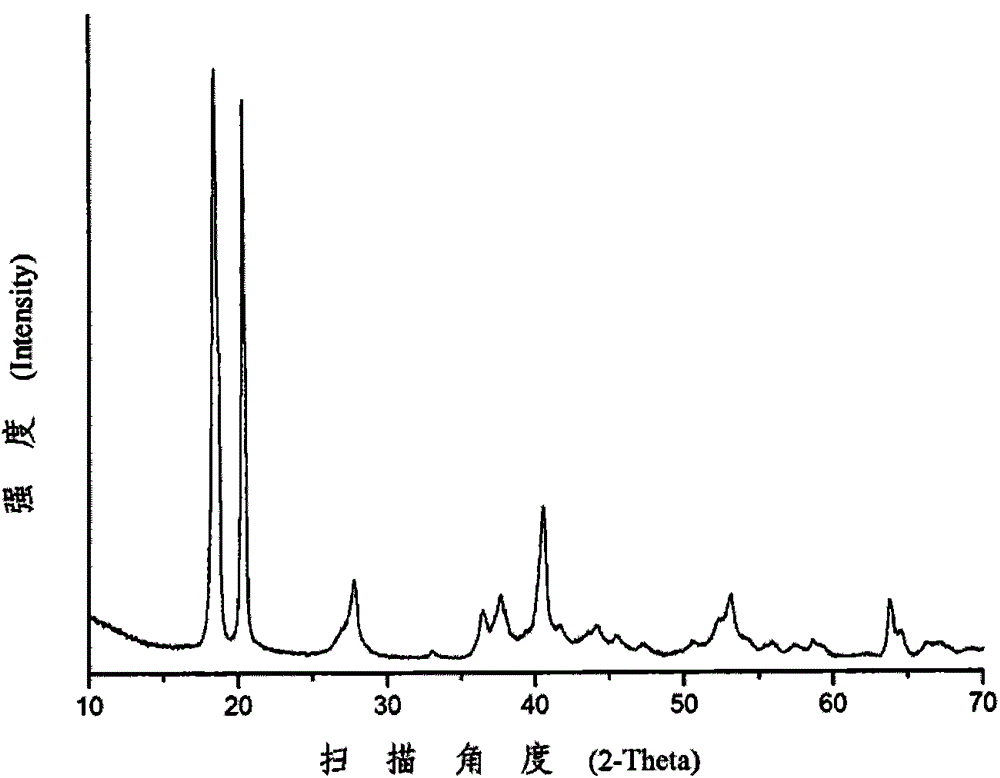

[0037] At a temperature of 100°C, crude aluminum hydroxide is dissolved in concentrated alkali solution with a mass concentration of 25% to prepare a concentrated metaaluminate saturated solution. The seed crystal prepared in Example 1 and the process water were formulated into a seed crystal slurry, and the concentrated metaaluminate saturated solution and the seed crystal slurry were quickly mixed in a ratio of 3:1 in a stator-rotor reactor at a temperature of 40°C, and fixed - The rotor speed is 3000rpm. The mixed reaction solution was circulated in the stator-rotor reactor for 40h to carry out crystallization. The solid product obtained by filtering and separating the crystallized reaction liquid is washed with process water, and then dried at 100° C. for 24 hours to obtain an ultrafine aluminum hydroxide product. The filtrate is used to evaporate and recover process water to prepare seed crystal slurry, and the concentrated filtrate is reused to dissolve crude aluminum h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com