Novel unloading crane pipe with oil-immersed pump

A technology of submersible oil pump and crane tube, which is applied in the field of new unloading crane tube, can solve the problems of poor sealing effect and difficult measurement, and achieve the effect of improving oil unloading speed, simple structure and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments.

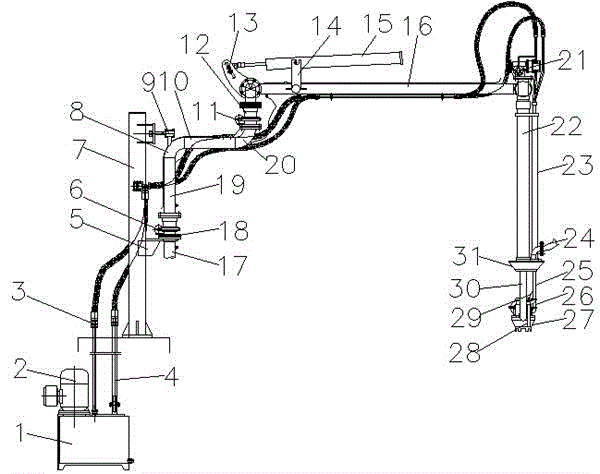

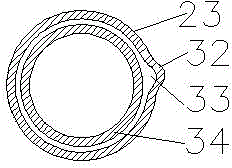

[0018] like figure 1 and figure 2 As shown, a new unloading crane pipe with a submersible pump includes a hydraulic oil storage tank 1, a vane pump 2, a negative pressure oil pipeline 3, a positive pressure oil pipeline 4, a pneumatic winch 21, a vertical pipe 22 and a submersible pump 27, and its characteristics In that: it also includes a support frame assembly, a rotating arm assembly, a gas phase pipe 24, an oil outlet pipe 25, an oil inlet pipe 26, a sleeve pipe 23, a liquid level gauge 28, an oil outlet 17, a telescopic pipe 30 and a sealing cover 31, the support frame The assembly includes a column 7, a rotating bracket 9 fixed to the upper and lower ends of the column 7, a seat frame 5, a vertical arm 19, a first rotary joint 18 and a first air motor 6, and the rotating bracket 9 and the seat frame 5 are arranged along the same vertical axis. The direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com