A vehicle right rear transverse link bracket assembly

A connecting rod bracket and bracket assembly technology, which is applied in the field of auto parts, can solve the problems of high brittleness and high hardness, and achieve the effect of high structural rigidity, simple structure, and prevention of lateral offset and rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

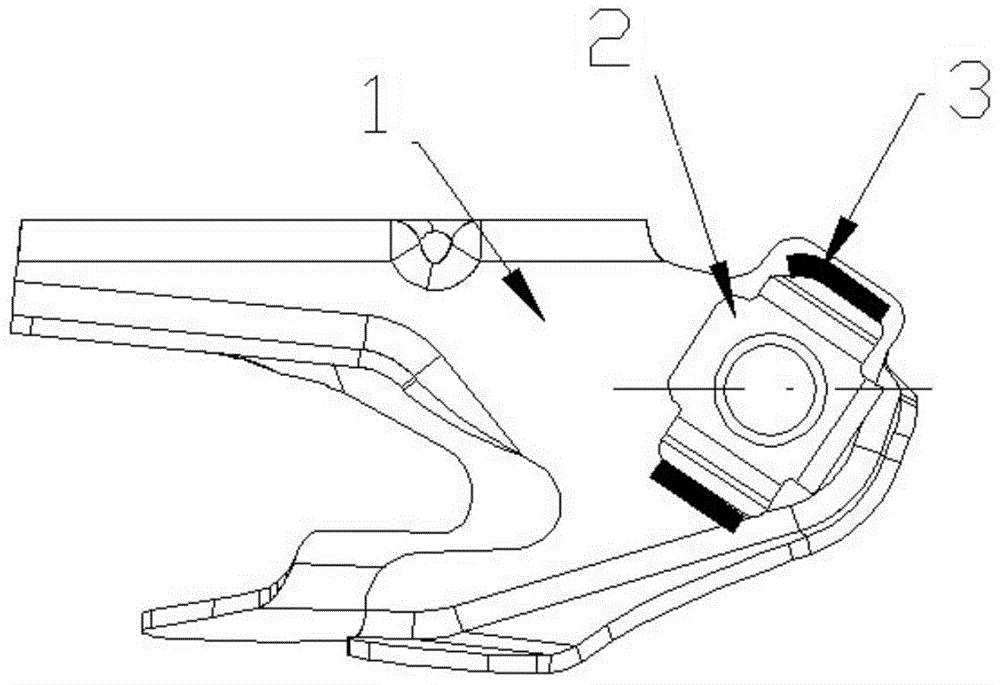

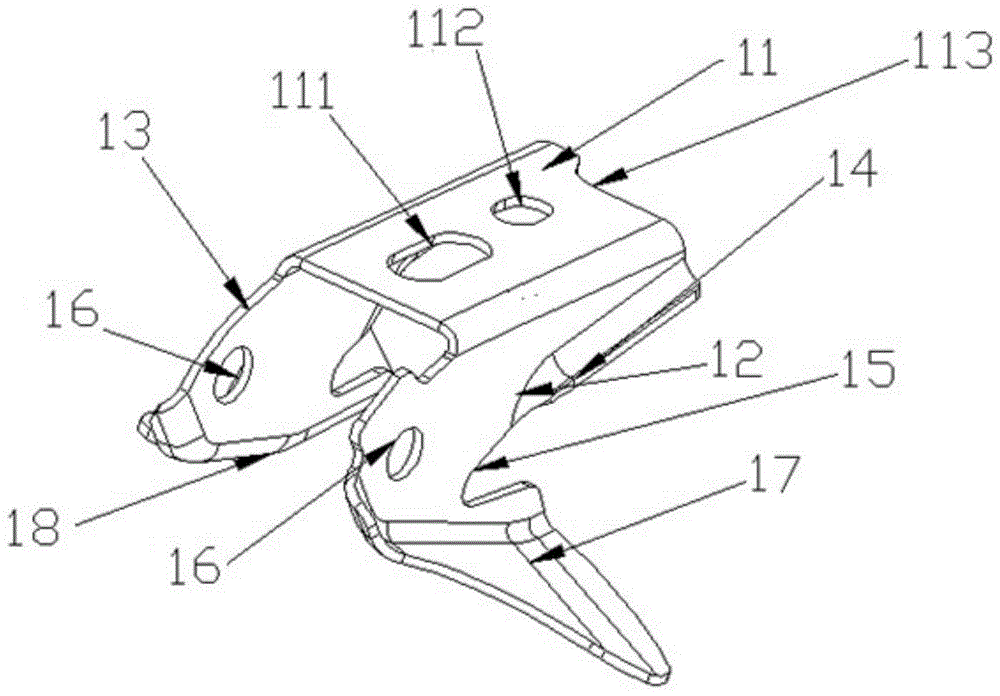

[0031] Such as figure 1 As shown, a vehicle right rear transverse link bracket assembly includes a link bracket body 1 and an anti-rotation bracket 2;

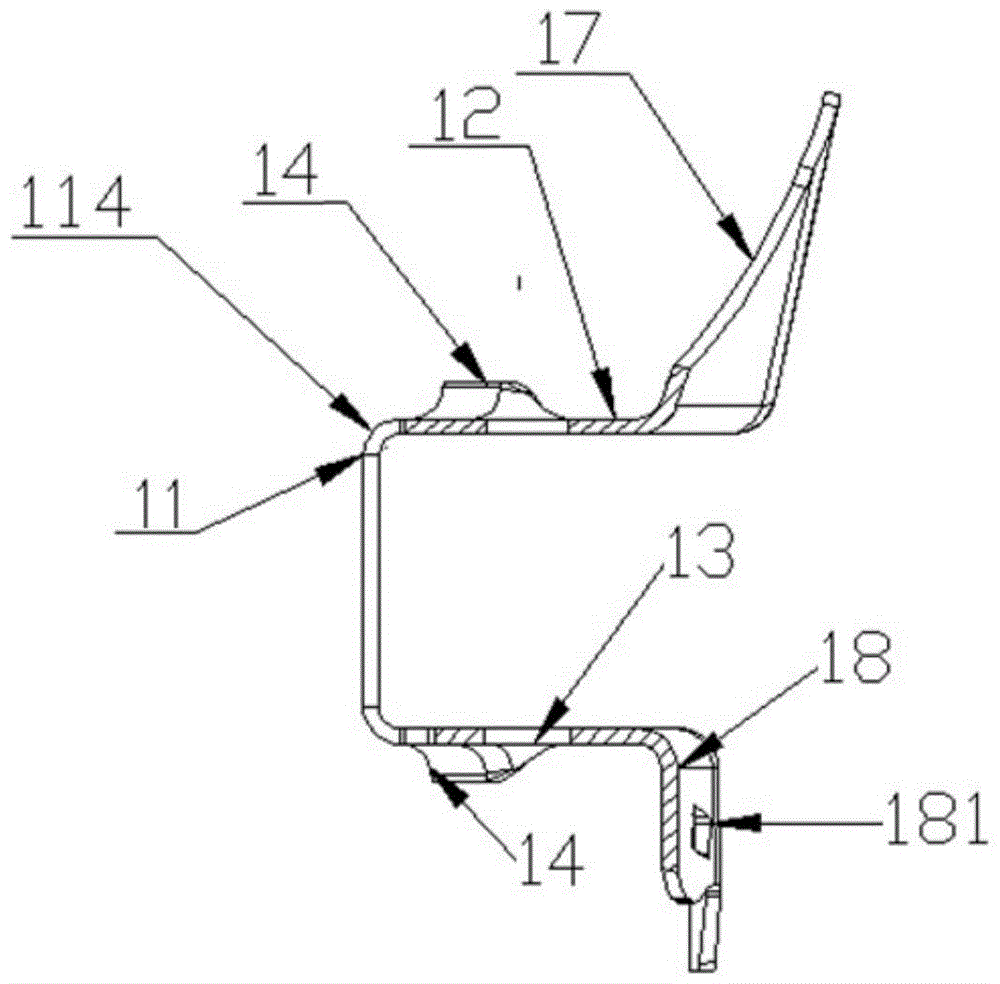

[0032] The connecting rod bracket body 1 includes a bracket bottom plate 11, the bracket bottom plate 11 has a first mounting hole 111 and a second mounting hole 112, and one end of the bracket bottom plate 11 has an escape groove 113;

[0033] The support bottom plate 11 is longitudinally bent on opposite sides of the outer edges to form a first side plate 12 and a second side plate 13;

[0034] The anti-rotation bracket 2 includes an anti-rotation base plate 21, and an anti-rotation mounting hole 211 is opened at the center of the anti-rotation base plate 21. Two opposite sides of the anti-rotation base plate 21 are respectively longitudinally bent to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com