Semiconductor processing apparatus and method

A processing device and semiconductor technology, which is applied to the surface coating liquid device, semiconductor/solid device manufacturing, surface pretreatment, etc. It can solve the problems that the needle tip is easy to touch the product, affects the gluing effect, and reduces work efficiency. , to achieve good glue spray effect, improve work efficiency, and accurate glue output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Several different preferred embodiments of the present invention will now be described with reference to the accompanying drawings, wherein like reference numerals in different drawings represent like parts. As mentioned above, the essence of the present invention lies in a semiconductor processing device and processing method, which has high gluing efficiency, accurate gluing position, and automatic curing treatment after gluing on the glue sprayer, thereby realizing efficient processing. The device and the method are applicable to any semiconductor components that need to be bonded by resin adhesives, and are not limited to the field of disk drives.

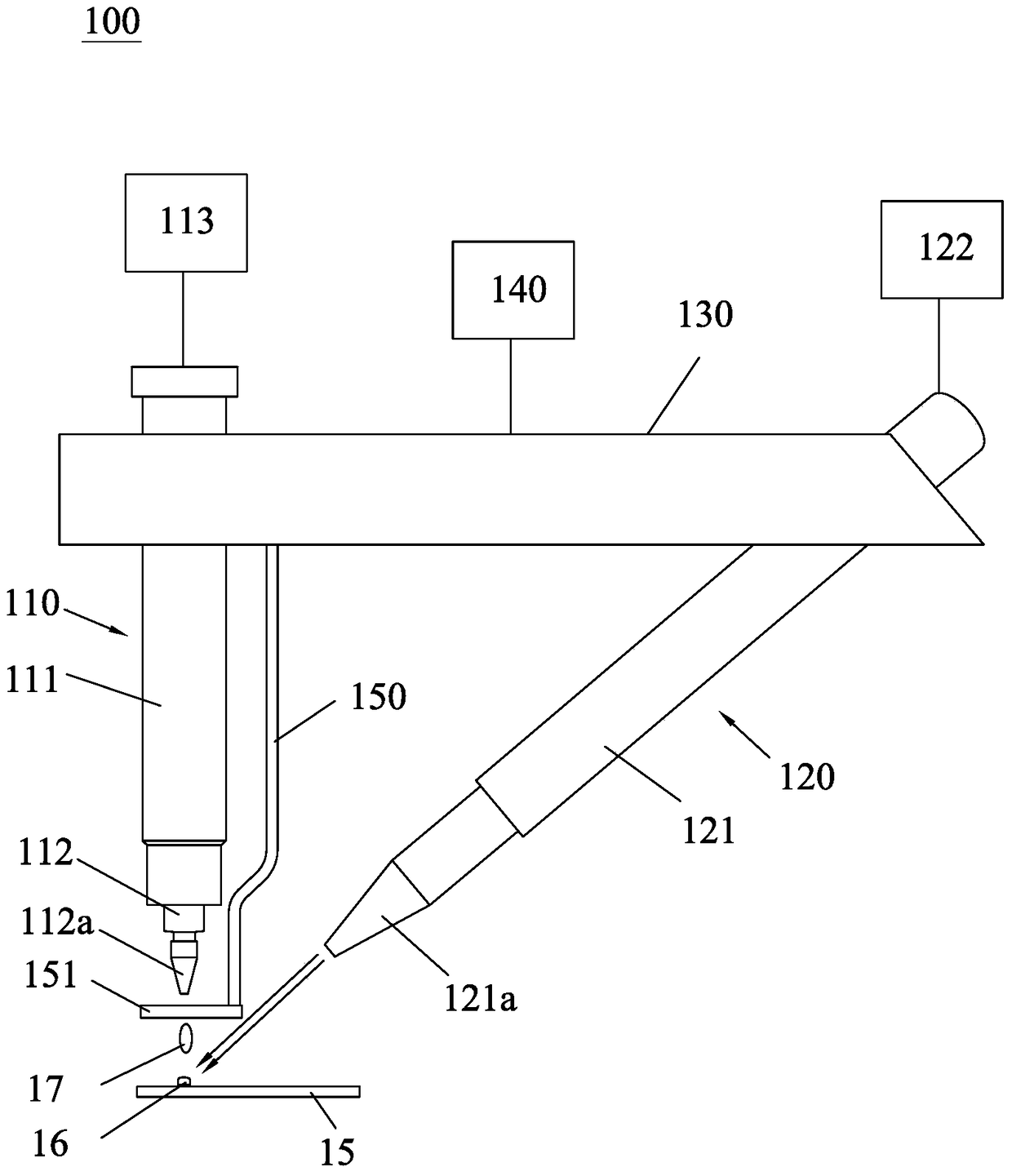

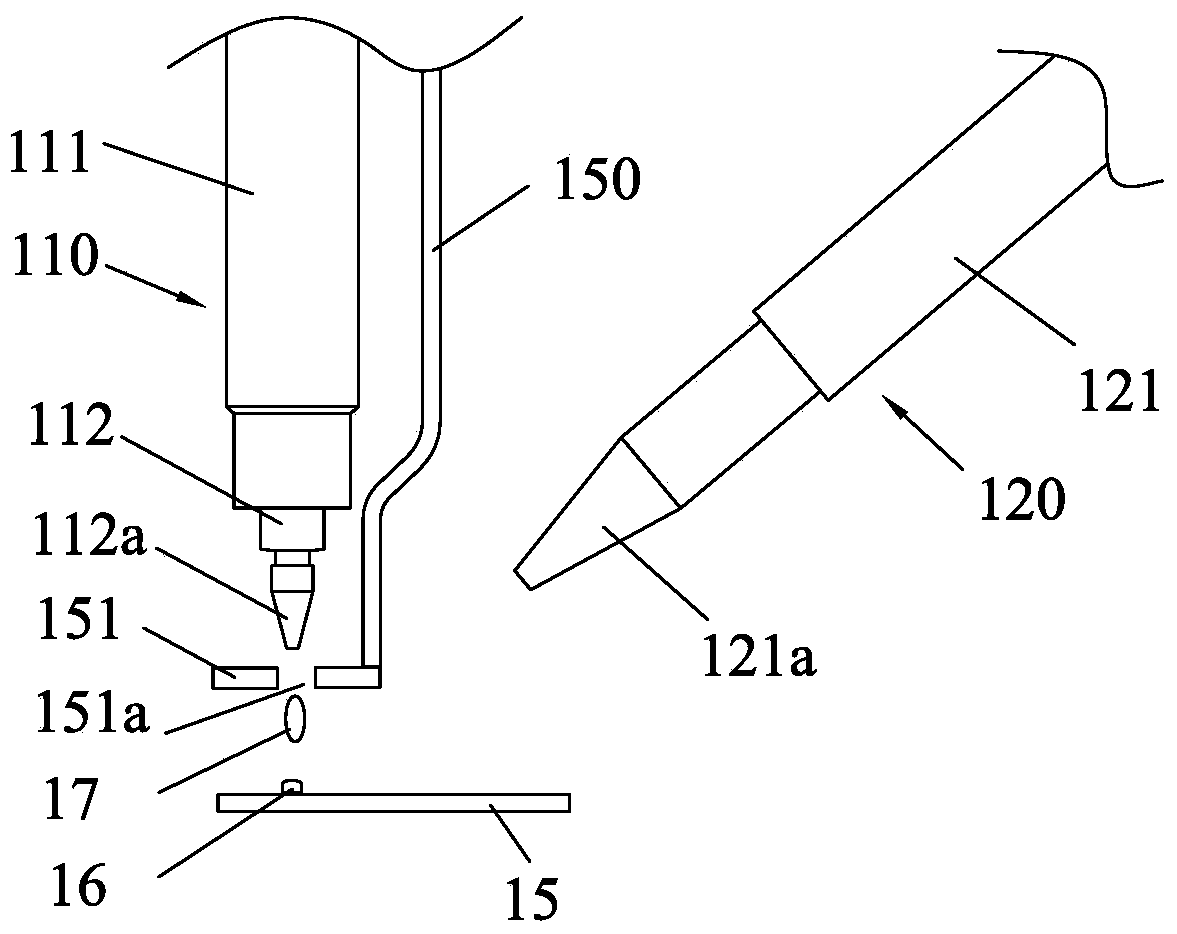

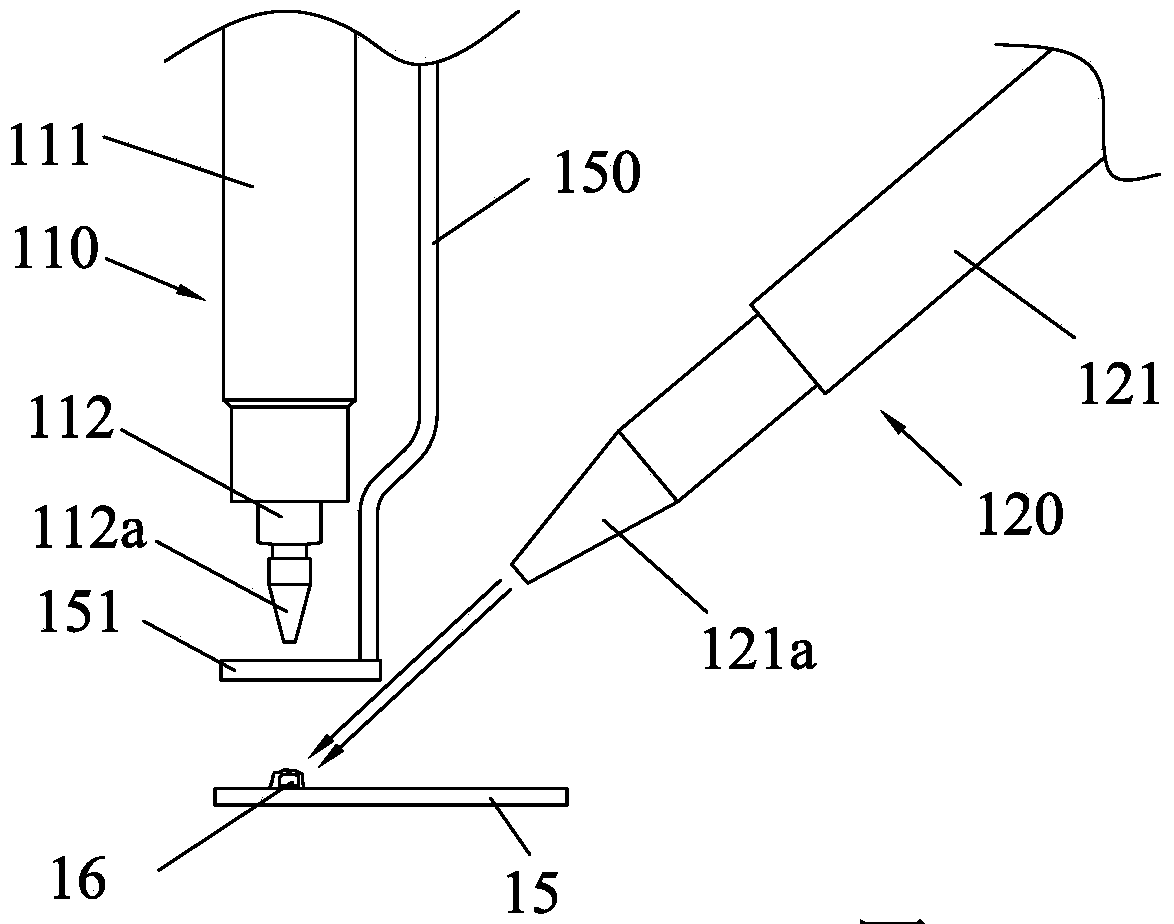

[0024] Please refer to figure 1 The semiconductor processing device 100 of the present invention includes a glue sprayer 110 , an ultraviolet light emitting device 120 , and a mounting plate 130 for installing the glue sprayer 110 and the ultraviolet light emitting device 120 . The glue spraying machine 110 in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com