Preparation and application of nano-structure composite adsorption material

A nanostructure composite and adsorption material technology, which is applied in the preparation of lanthanum nitrate modified mesoporous silicon materials and the preparation of nanostructure composite adsorption materials, can solve the problems of serious environmental pollution, improve adsorption capacity, reduce production costs, The effect of the simple and easy operation of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Ultrasonic disperse the cellulose nanocrystal solution, add 70 mg of anhydrous glucose to 5 ml of the suspension solution, add 0.18 ml of methyl orthosilicate TMOS dropwise, mechanically stir in a water bath at 25 ° C for 1 h, pour into an evaporating dish, and place Evaporate to dryness in an oven at 23°C, and calcinate at 540°C for 6 hours to obtain a mesoporous silicon membrane material;

[0032] (2) Put the mesoporous silicon membrane material obtained in step (1) in 90ml of ethanol solution, add 0.09g of hexahydrate lanthanum nitrate crystals, shake in a water bath at 60°C for 24h, dry at 80°C, and calcined at 550°C for 6h to obtain Modified mesoporous silicon membrane material, that is, nanostructure composite adsorption material.

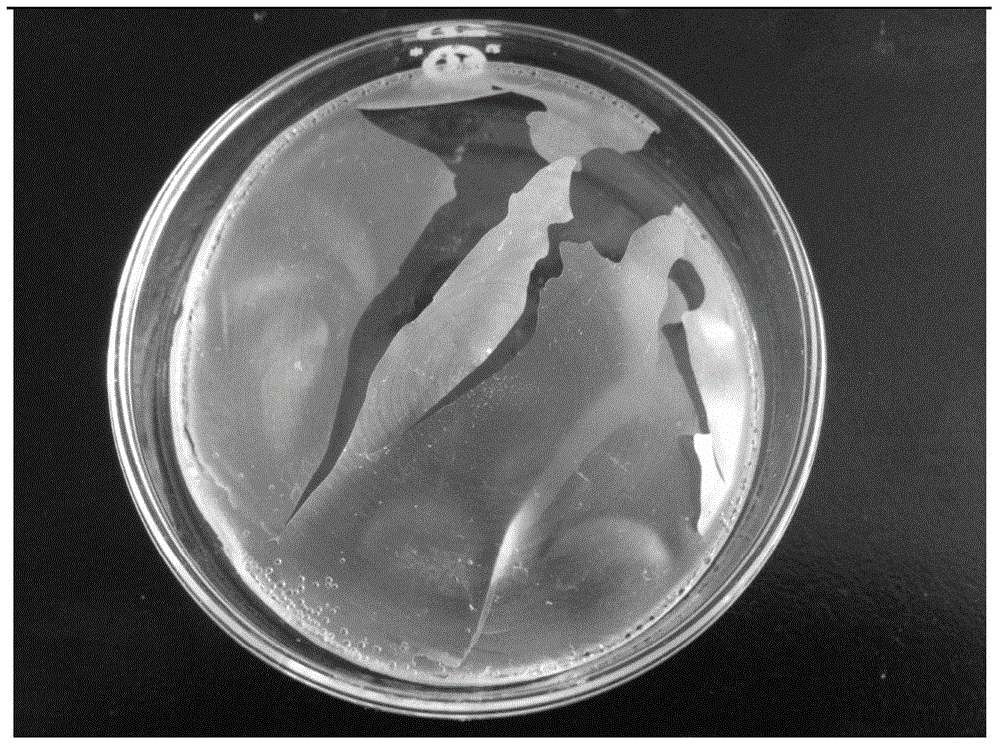

[0033] (3) Photos of nanostructured composite adsorption materials such as figure 1 shown.

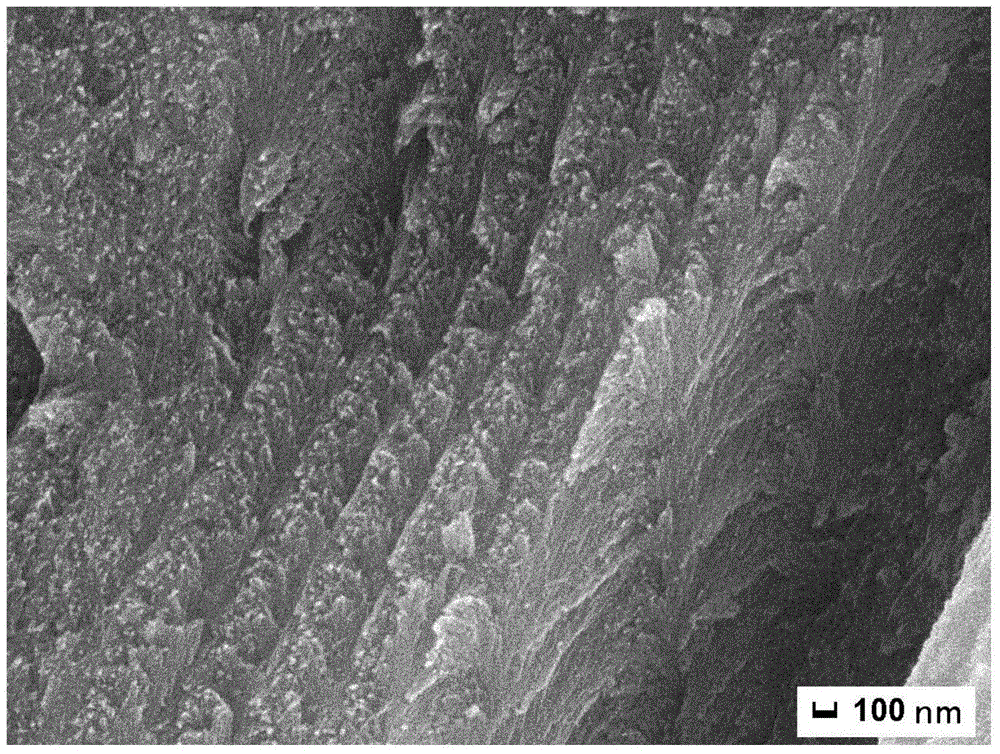

[0034] (4) The scanning electron microscope image of the nanostructure composite adsorption material is as follows figure 2 as shown, ...

Embodiment 2

[0038] (1) Ultrasonic disperse the cellulose nanocrystal solution, add 80 mg of anhydrous glucose to 5 ml of the suspension solution, add 0.2 ml of methyl orthosilicate TMOS dropwise, mechanically stir in a water bath at 25 ° C for 1 h, pour into an evaporating dish, and place Evaporate to dryness in an oven at 25°C, and calcinate at 540°C for 6 hours to obtain a mesoporous silicon membrane material;

[0039] (2) Put the mesoporous silicon membrane material obtained in step (1) in 100ml of ethanol solution, add 0.11g of hexahydrate lanthanum nitrate crystals, shake in a water bath at 60°C for 24h, dry at 80°C, and calcined at 550°C for 6h to obtain Modified mesoporous silicon membrane material, that is, nanostructure composite adsorption material.

[0040] (3) The prepared nanostructured composite adsorption material was used in the separation and adsorption experiments of phosphate ions.

[0041] Phosphate ions are taken to form a series of phosphorus-containing aqueous solu...

Embodiment 3

[0047] (1) Ultrasonic disperse the cellulose nanocrystal solution, add 90 mg of anhydrous glucose to 5 ml of suspension solution, add 0.22 ml of methyl orthosilicate TMOS dropwise, mechanically stir in a water bath at 25 ° C for 1 h, pour into an evaporating dish, and place Evaporate to dryness in an oven at 28°C, and calcinate at 540°C for 6 hours to obtain a mesoporous silicon membrane material;

[0048] (2) Put the mesoporous silicon membrane material obtained in step (1) in 110ml of ethanol solution, add 0.13g of lanthanum nitrate crystals of hexahydrate, shake in a water bath at 60°C for 24h, dry at 80°C, and calcined at 550°C for 6h to obtain Modified mesoporous silicon membrane material, that is, nanostructure composite adsorption material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com