Method for testing environmental adaptability of optical fiber sensing system

A fiber optic sensing system, a technology of environmental adaptability, applied in control/regulation systems, non-electric variable control, instruments, etc., can solve the problem of difficult to find component failures and design defects, reduce the severity of the test, and cannot find the root cause of the problem, etc. problems, to achieve the effect of easy failure and design defects, avoid repeated tests, and shorten the test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

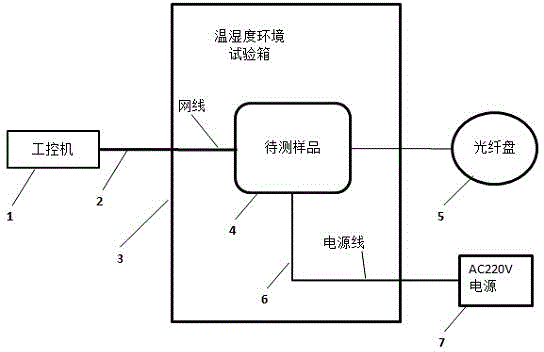

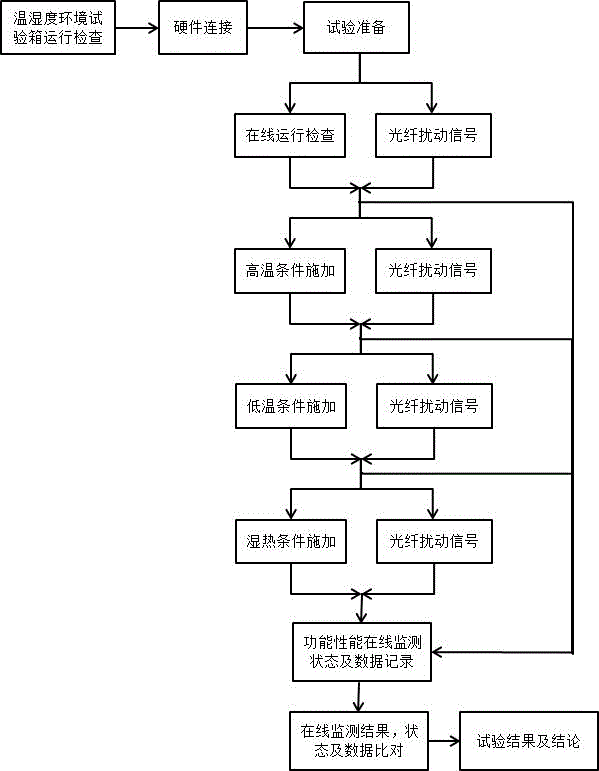

[0024] Below we will further describe in detail the method principle and operation process of the optical fiber sensing system environmental adaptability test of the present invention in conjunction with the accompanying drawings and specific embodiments, in order to understand its implementation process and working steps more deeply, but cannot In this way, the protection scope of the present invention is limited.

[0025] The purpose of the present invention is to provide a combined environmental adaptability test scheme, which simulates the temperature and humidity environment that may occur in the normal use of the product, and checks its operation in this environment; through the system control software in the external industrial computer and Optical fiber, real-time monitoring of product functional stability and performance changes in a simulated environment; and accelerated aging of product components to accelerate the exposure of product component failures and design de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com