An experimental device and method for simulating secondary explosion in situ

A secondary explosion and experimental device technology, applied in the direction of material inspection products, fuel oil testing, etc., can solve the problems of danger, high operating environment requirements, and inability to study secondary explosions in situ, and meet the low requirements of the experimental environment and safety The effect of high coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

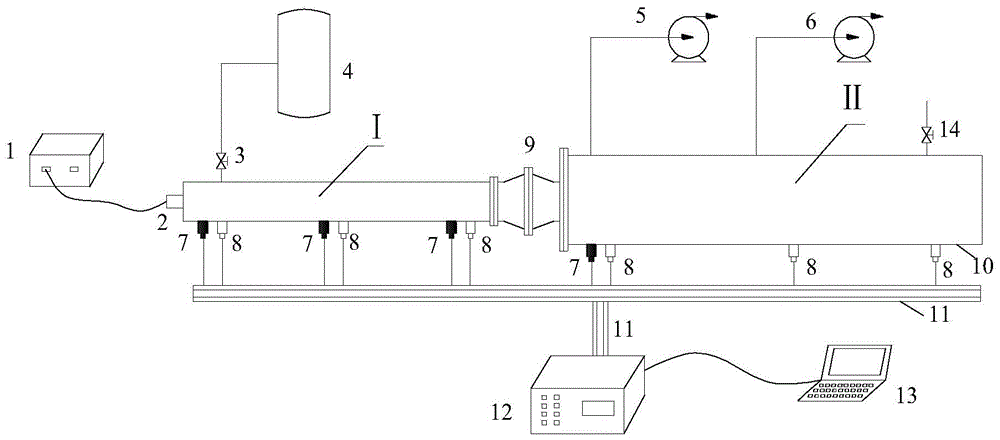

[0026] Attached below figure 1 Further description will be given to specific embodiments of the present invention.

[0027] like figure 1 The experimental device for simulating "in situ secondary explosion" includes igniter 1, ignition head 2, air inlet 3, air storage bag 4, vacuum pump 5, circulation pump 6, flame sensor 7, pressure sensor 8, flame arrester 9 , Explosion pipeline 10, hub board 11, data acquisition instrument 12, computer 13, exhaust port 14. The main part of the device is an explosion pipeline 10, and a flame arrester 9 is arranged in the middle of the explosion pipeline 10. The flame arrester 9 divides the explosion pipeline into two parts, which are respectively the first pipeline I and the second pipeline II. When the mixed gas is ignited, the gas in the first pipeline I explodes for the first time, but the gas in the second pipeline II will not explode due to the flame arresting effect of the flame arrester 9 . After the primary explosion in the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com