Device for detecting heating mass of substances and gas sampling synchronously online

A technology of gas sampling and synchronous detection, applied in the sampling device and weighing by removing certain components, can solve the problems of small mass change, high weighing accuracy, and difficult measurement data, and achieve the effect of avoiding mass loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

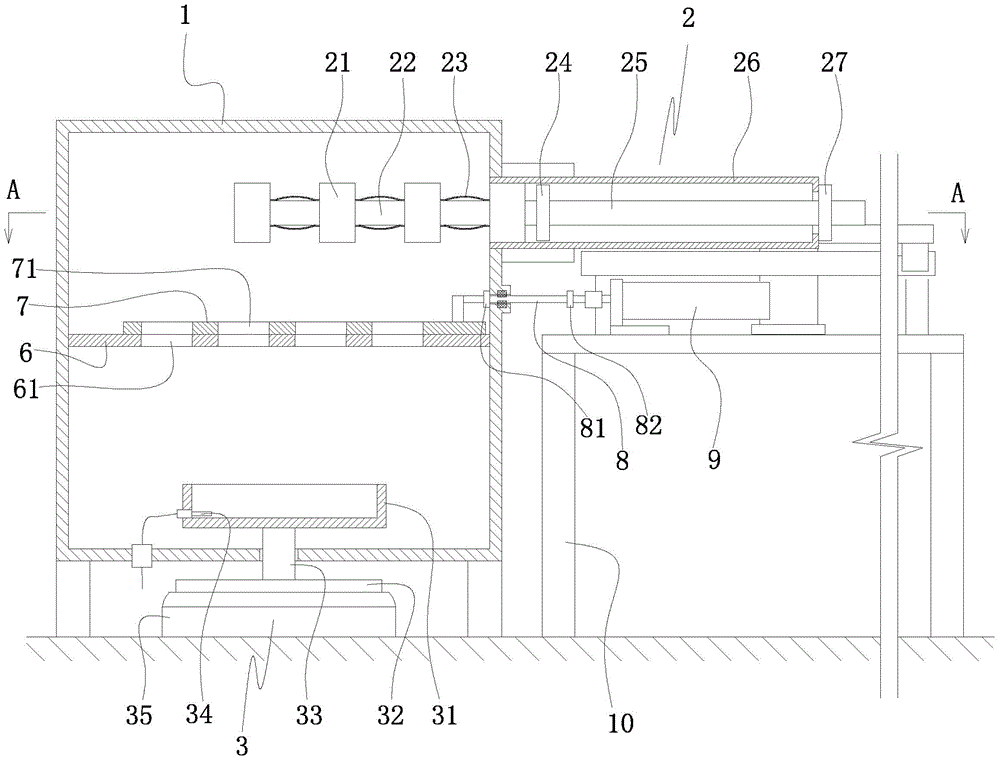

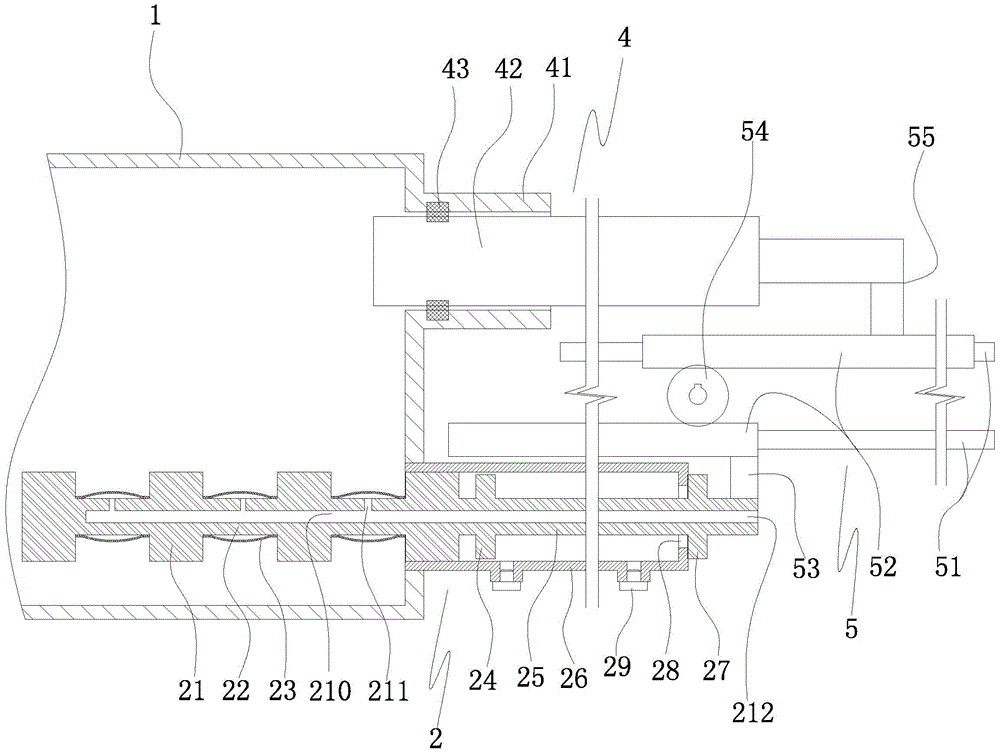

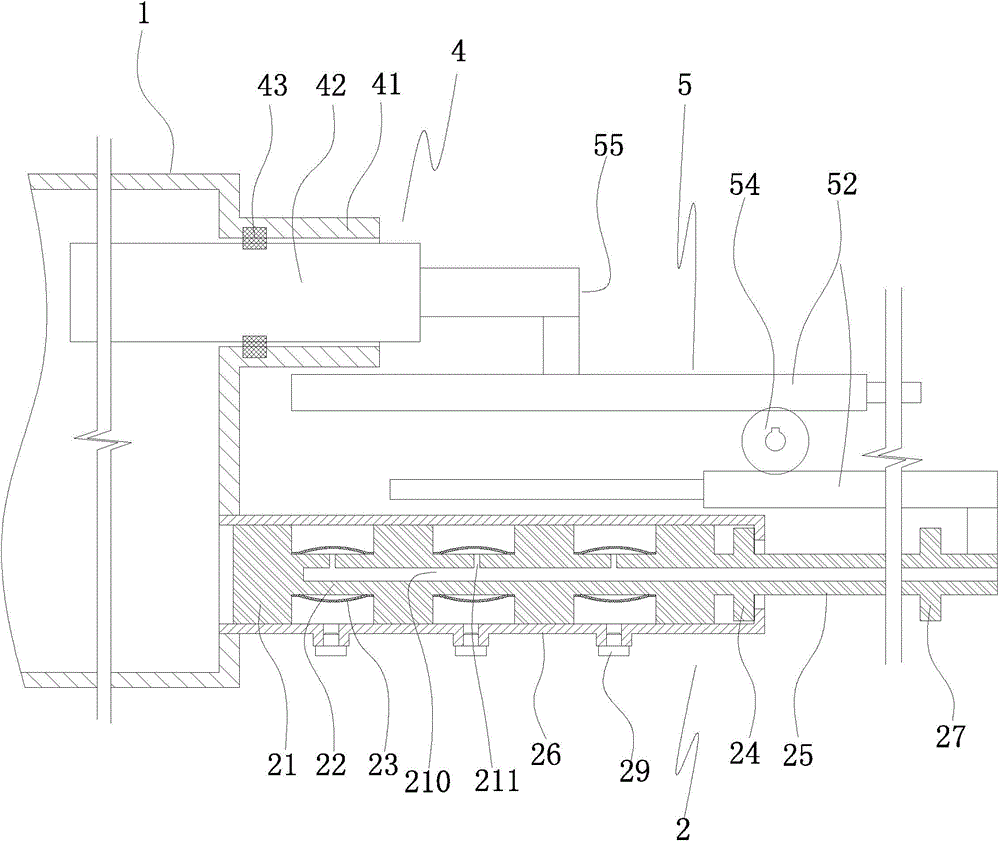

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0023] like figure 1 , figure 2 As shown, an online synchronous detection of the heating quality of substances and a gas sampling device includes an oven 1, a mounting frame 10, an electronic weighing device 3 arranged at the bottom of the oven for weighing the quality of the substance, a gas sampling device 2 arranged on the oven and Volume compensation device 4. The inner cavity of the oven is a sealed cavity. The side of the oven is provided with a sealed box door. There are supporting feet at the bottom of the oven. The oven is provided with a thermometer for detecting the temperature of the inner cavity of the oven. An electric heater is also provided on the oven.

[0024]A partition 6 is arranged in the middle of the oven, and the partition is arranged horizontally. The electronic weighing device is located below the partition, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com