Micro power digital pressure gauge and pressure measuring method

A pressure gauge and micro-power consumption technology, which is applied in the direction of fluid pressure measurement by changing ohmic resistance, can solve the problems of inability to use overpressure, decreased measurement accuracy, short service life, etc., and achieves strong overpressure capability and good reliability. , the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

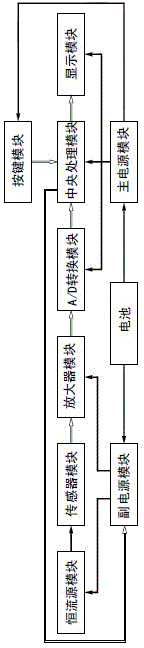

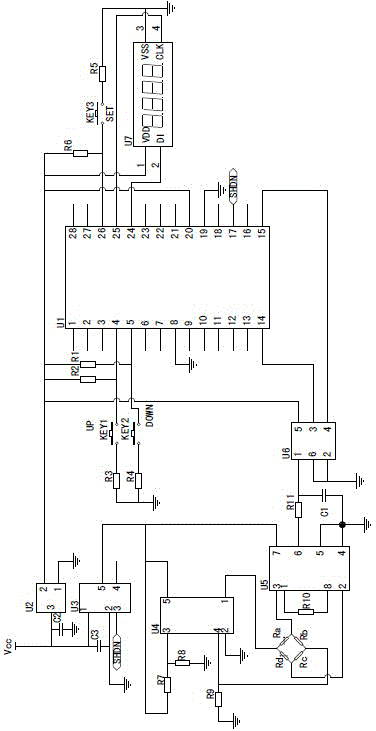

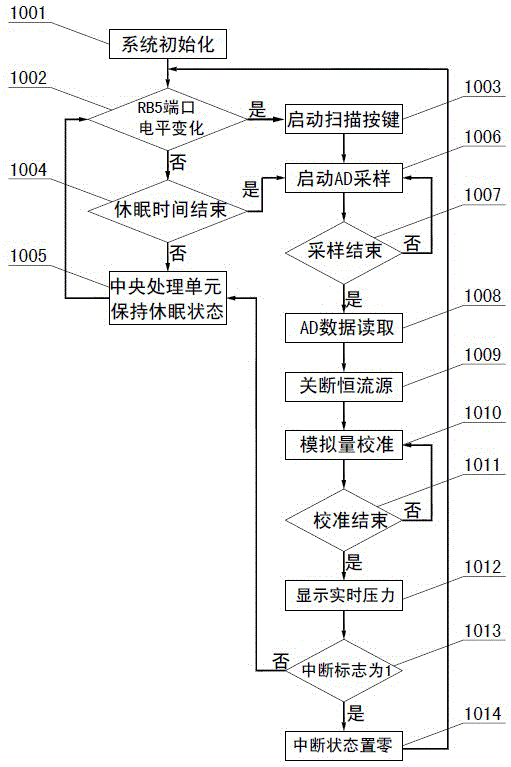

[0082] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~4 The present invention will be further described.

[0083] exist figure 1 In the schematic block diagram of the micro-power consumption digital pressure gauge shown, the black arrow indicates the flow direction of the power supply signal, and the white arrow indicates the flow direction of the control signal. The micro-power consumption digital pressure gauge includes a power supply unit, a sensor unit and a data processing unit, the sensor unit is connected to the data processing unit, and the power supply unit supplies power to the sensor unit and the data processing unit at the same time. The power supply unit includes a battery and a main power module and an auxiliary power module connected to the battery. The main power module and the auxiliary power module are realized by a voltage stabilizing chip, which respectively convert the output voltage of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com