Fluidized bed boiler for incinerating straws

A fluidized bed boiler and straw technology, which is applied in the directions of fluidized bed combustion equipment, combustion method, combustion type, etc., can solve the problems that the boiler cannot be used for straw fuel, the boiler is easy to accumulate ash and heat energy conversion, and the pollutant emission is high. The effect of good fuel ash activity, good market prospect and low combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

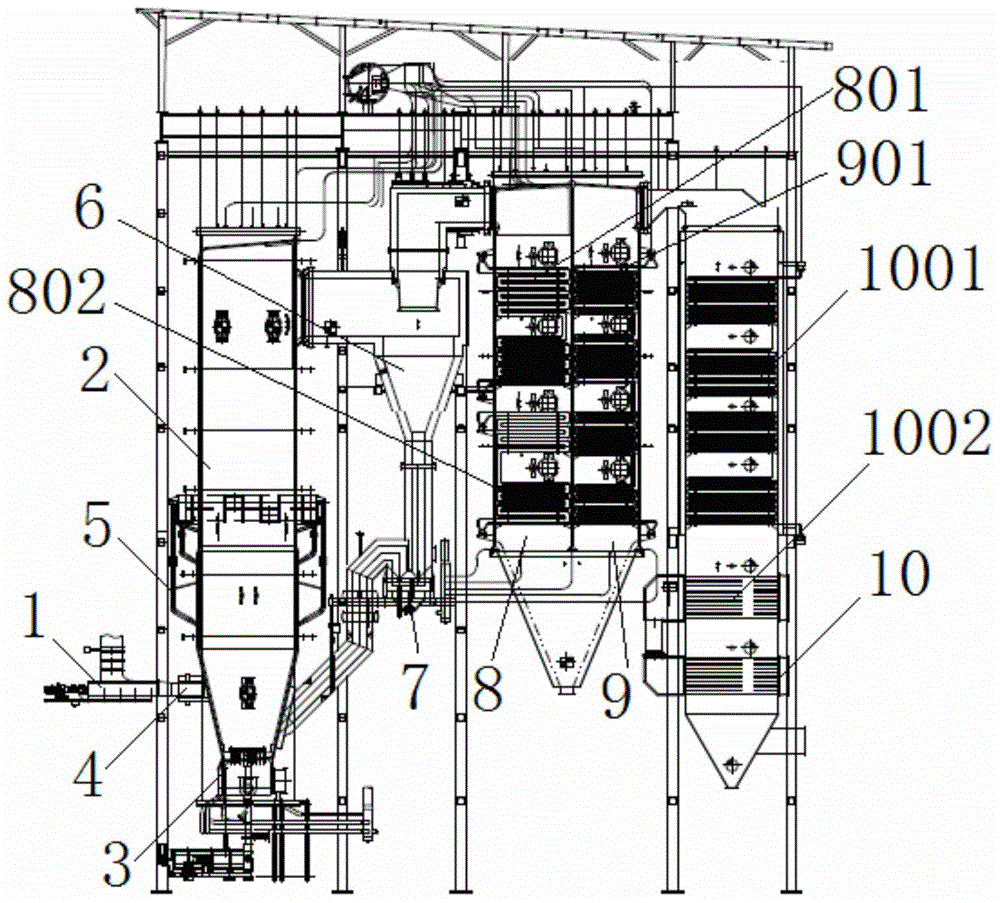

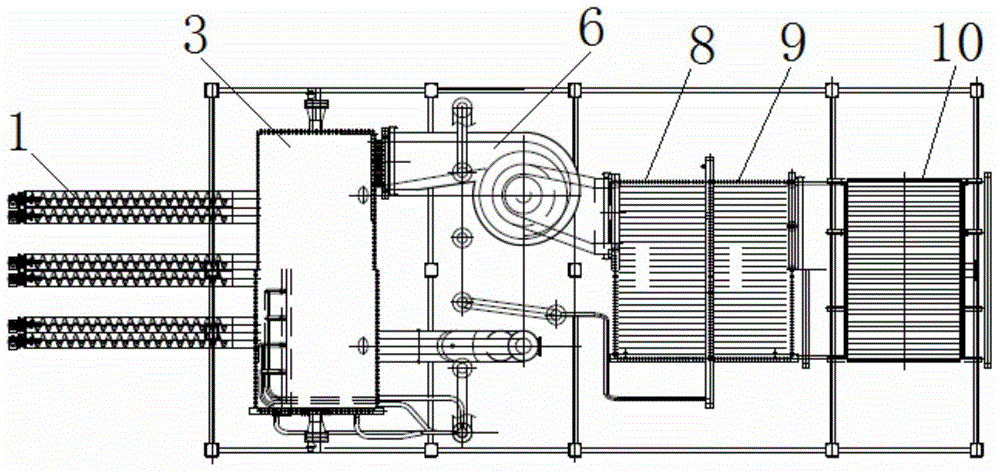

[0034] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

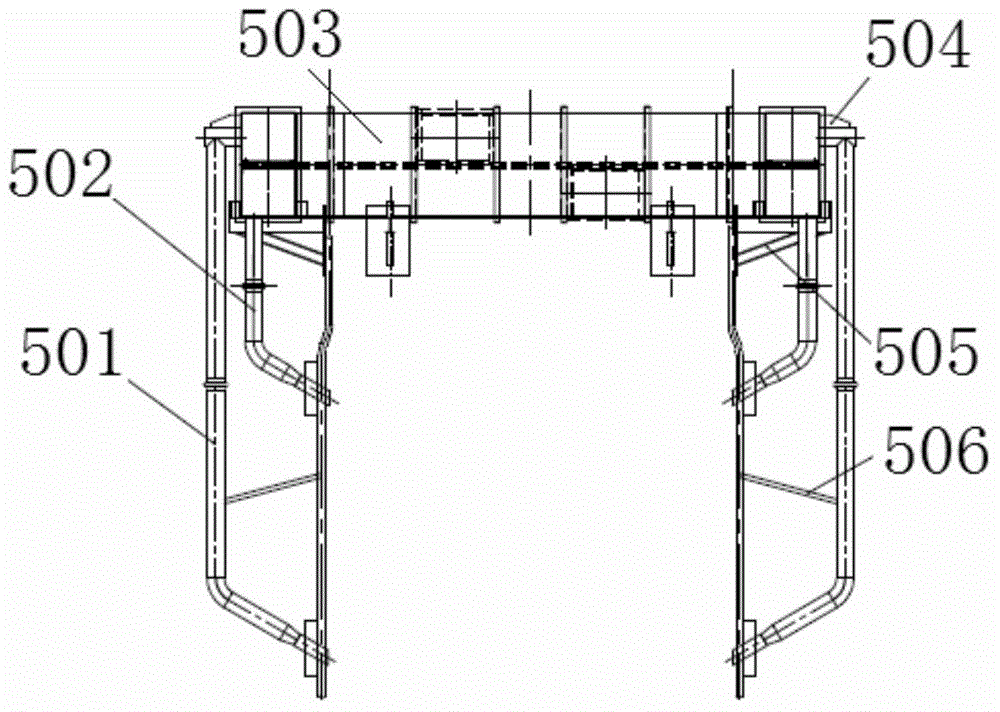

[0035] like Figure 1 to Figure 7 As shown, the straw incineration fluidized bed boiler includes a feeding mechanism 1, a furnace 2, an ignition mechanism 3, a flue, a material circulation system, and a secondary air intake mechanism 5, wherein the furnace 2 is vertically arranged, and the furnace 2 is supported It is fixed in combination with hanging, the evaporation heating surface of the furnace adopts membrane water-cooled wall, and the flue at the tail adopts water-cooled cladding wall.

[0036] The material circulation system includes a cyclone separator 6, the inlet of the cyclone separator 6 is connected to the top of the furnace 2, the outlet of the lower part of the cyclone separator 6 is connected to the bottom of the furnace through a pipeline and a return valve 7 is provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com