Suspension rail type rock drilling machine

The utility model relates to a rock drilling rig and a suspension rail type technology, which is applied to the suspension rail type rock drilling rig, drilling operation equipment, and rock drilling fields. , The effect of shortening operation time and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

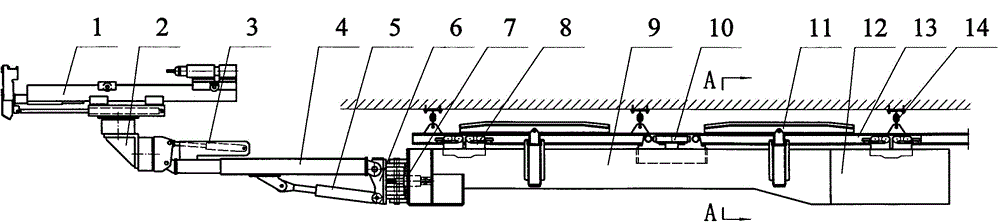

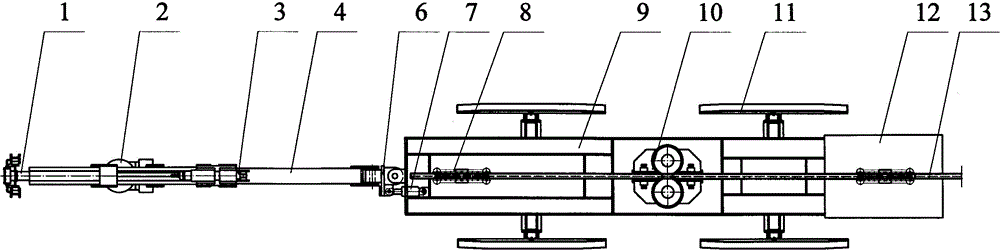

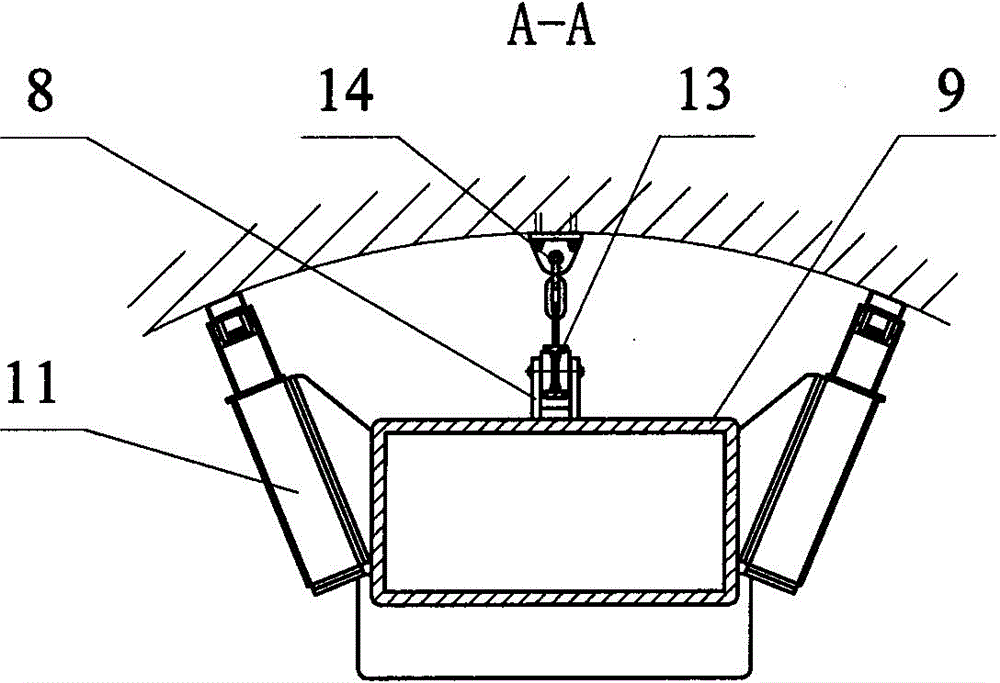

[0021] according to Figure 1-9 The specific structure of the present invention will be described in detail. The suspension rail rock drilling rig can be made into type I according to the actual use requirements (such as Figure 1~2 shown) structure or type II (such as Figure 8-9 shown) structure. It includes body 9, rock drilling device 1, running gear and hydraulic pump station 12 etc. parts. Taking the type I structure as an example, the body 9 is assembled on the traveling track 13 through the driving wheel 10 and the driven wheel 8 of the traveling mechanism, and the driven traveling wheel 8 and the driving wheel 10 that support and walk along the traveling track 13 are fixed by brackets On airframe 9. In order to facilitate braking and positioning during operation, a braking device (not shown in the drawings) is provided on the driving wheel 10 . Walking track 13 utilizes hanging fastener 14 to hang on the roadway top, and walking track 13 can adopt single track or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com