Upright inserted high-voltage line maintaining ladder

A high-voltage line, plug-in technology, applied to overhead lines/cable equipment, ladders, buildings, etc., can solve problems such as unstable high-voltage lines, unfavorable environmental protection, and damage to the green environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

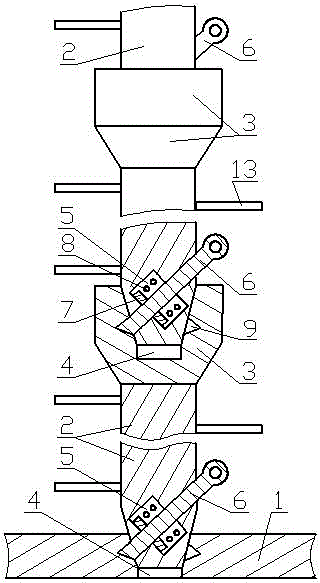

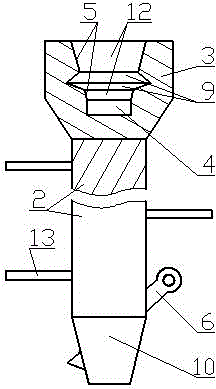

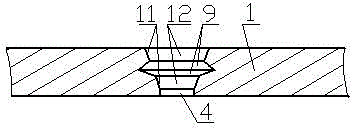

[0048] The vertical plug-in high-voltage line maintenance ladder of the present invention mainly includes a stable seat 1, a column body, a brake hole 5, a brake pin 6, a locking spring 8, a thrust plate 7, a locking groove 9, an outer cone surface 10, an inner cone Hole 12, inner tapered surface 11;

[0049] The middle part of the stable seat 1 has an inner cone hole 12, an air gap groove 4 is arranged below the inner cone hole 12, and an annular locking groove 9 is arranged on the inner cone surface 11 of the inner cone hole 12; The outer cone surface 10 and the other end have an inner cone hole 12, the outer cone surface 10 is at one end of the column 2, the inner cone hole 12 is at one end of the connector 3, and there is an air gap groove 4 inside the inner cone hole 12, and the inner cone There is an annular locking groove 9 on the inner cone surface 11 of the hole 12, and a foldable foot step that can be folded in to one end of the connector 3 of the column body is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com