Concrete composite shear wall and construction method thereof

A technology of combining shear walls and concrete walls, applied in the direction of walls, buildings, building components, etc., can solve the problems of increasing weight, steel consumption, and increasing costs, and achieves low steel consumption, low cost, and low self-weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

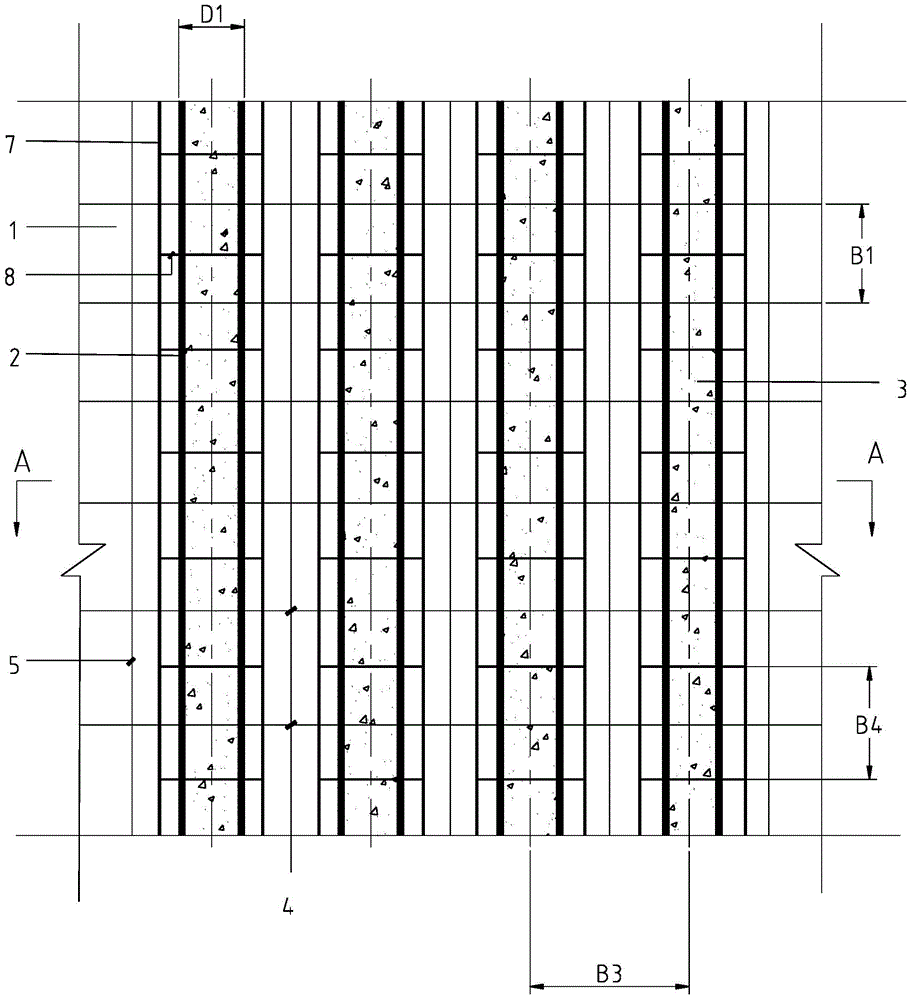

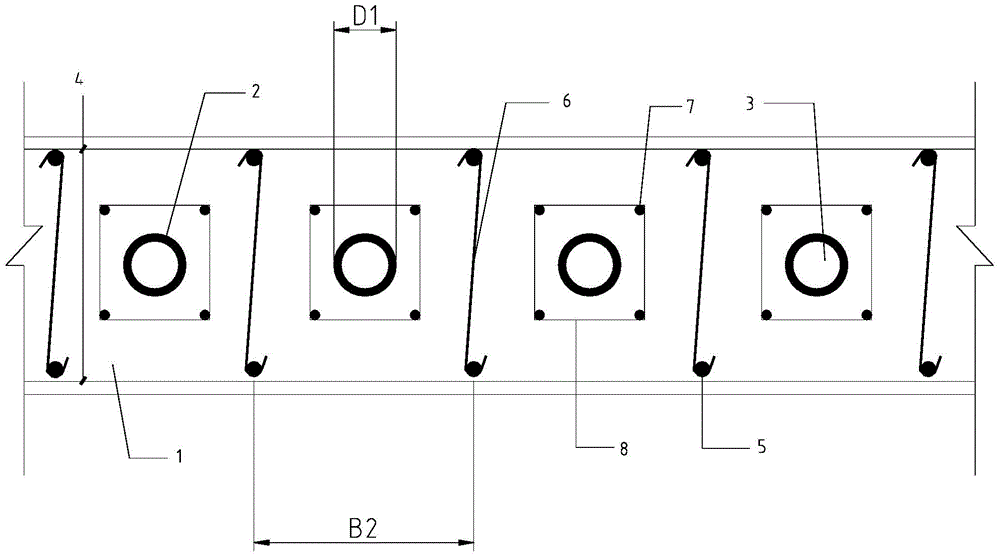

[0025] The structure of the concrete composite shear wall of the embodiment of the present invention is as follows figure 1 and figure 2 As shown, it includes a concrete wall 1 and a plurality of PVC concrete pipes, the plurality of PVC concrete pipes are arranged separately along the length direction of the concrete wall 1, and the PVC concrete pipes are placed on the steel bars formed by binding and fixing the vertical bars 7 and stirrups 8 The center of the cage is vertically embedded in the concrete wall 1 .

[0026] The concrete walls 1 on both sides of the PVC concrete pipe array each include a grid net composed of steel bars, and the two grid nets are connected by tie bars 6 .

[0027] The PVC concrete pipe is composed of a PVC double-wall corrugated pipe 2 and concrete 3 poured into the PVC double-wall corrugated pipe 2 .

[0028] The grid net includes horizontal steel bars 4 and vertical steel bars 5, the spacing B1 between the horizontal steel bars 4 is 2-6 times ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com