Dual-rolling broom sweeping mechanism for sweeping vehicle

A cleaning mechanism and cleaning vehicle technology, applied in road cleaning, cleaning methods, construction and other directions, can solve the problems of inability to move up and down freely, high input costs, high maintenance costs, and achieve low cost, reduce energy consumption, and extend service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

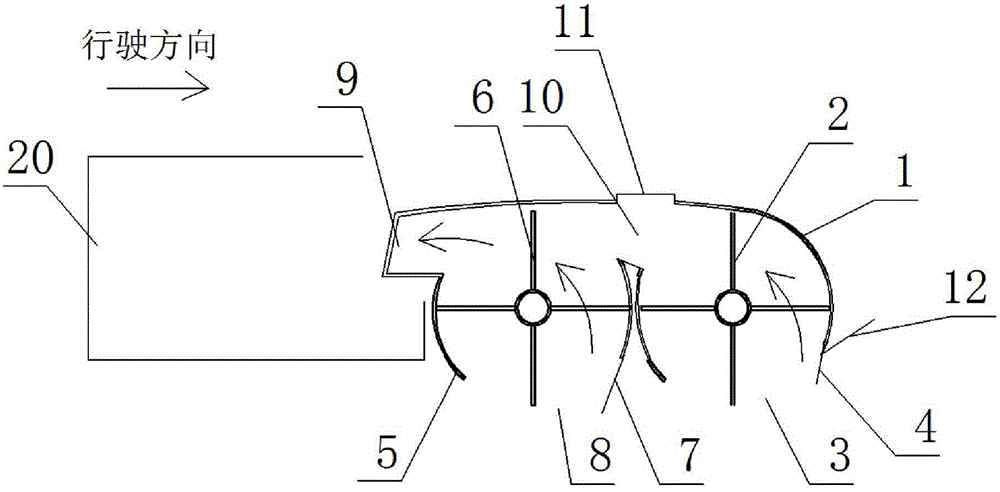

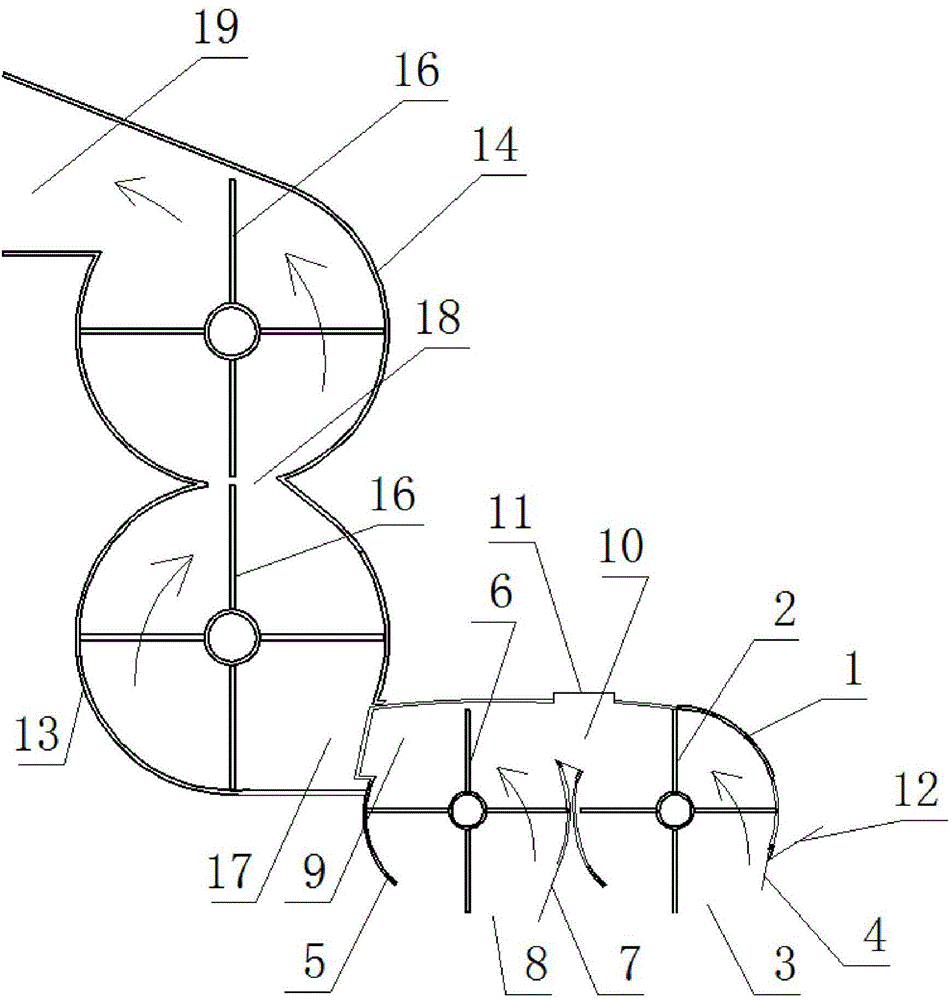

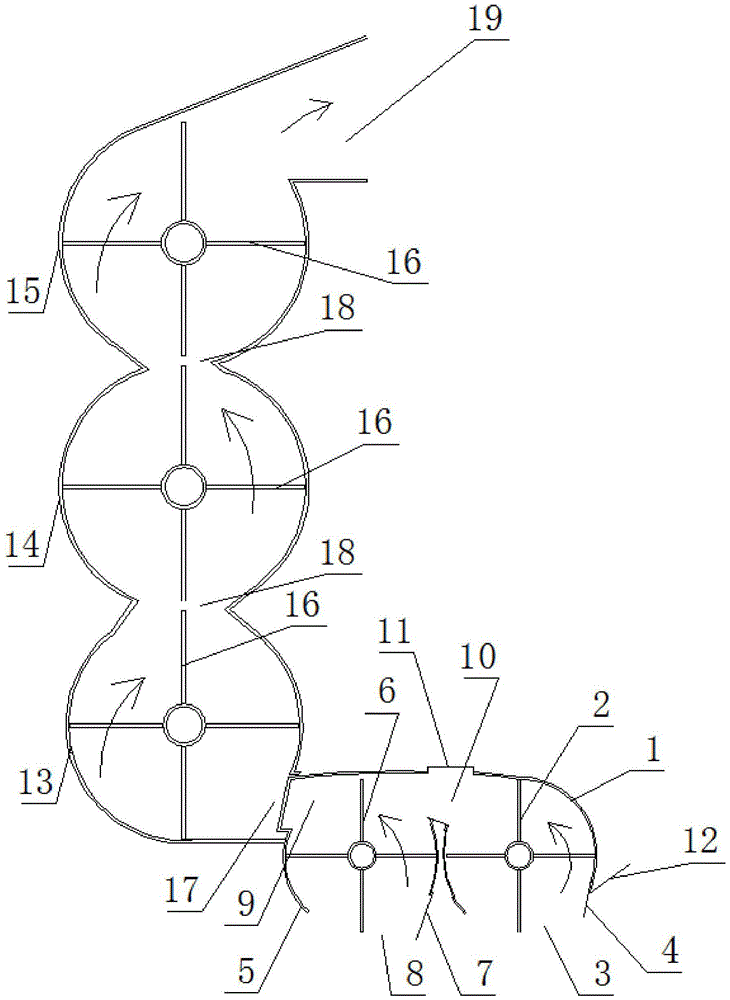

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] Such as figure 1 , figure 2 , image 3 Shown, a kind of sweeping vehicle double-roller sweeping cleaning mechanism of the present invention comprises by front rolling sweeping outer cover 1, forward rolling sweeping 2, forward rolling sweeping garbage inlet 3, forward rolling sweeping elastic dust guide plate 4, rear rolling sweeping The outer cover 5, the rear rolling sweep 6, the rear rolling sweeping elastic dust guide plate 7, the rear rolling sweeping garbage inlet 8, the rear rolling sweeping garbage outlet 9, etc., the front rolling sweeping 2 and the rear rolling sweeping 6 are the same 200810071548.X has the same or similar structure of the main and auxiliary rolling sweeps, but the rotation principle is different, and the garbage passage is completely different . The front rolling sweep cover 1 is connected with the rear rolling sweep cover 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com