Anti-reflection-crack waterproof coiled material used in airport runway and construction method thereof

A technology for airport runways and waterproofing membranes, which can be applied in the directions of roads, roads, and pavement details. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

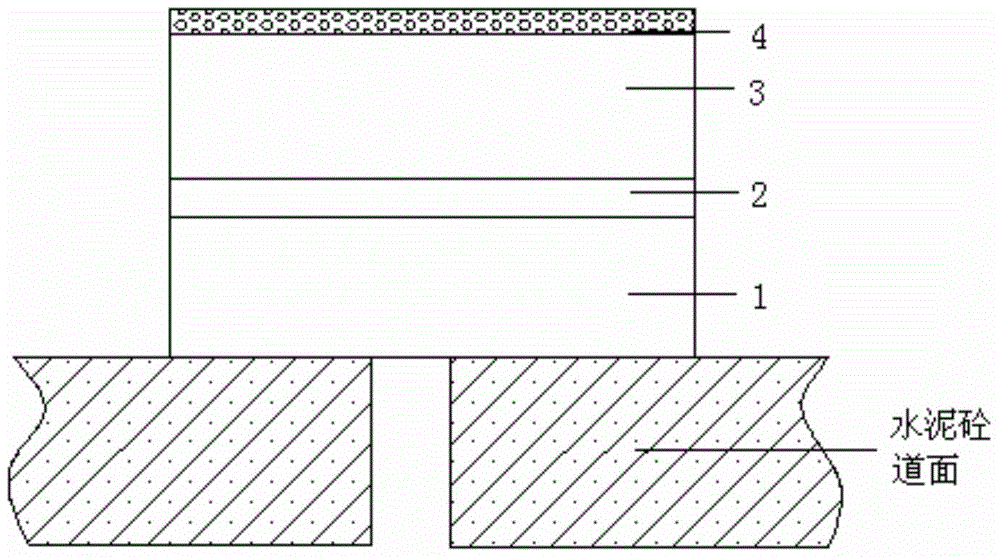

[0017] Examples of the present invention figure 1 As shown, the first stress dissipating layer 1, the second stress dissipating layer 2, the third stress dissipating layer 3 and the slab layer 4 are arranged sequentially from bottom to top, and the first stress dissipating layer 1 is composed of specially-made modified asphalt; The second stress dissipating layer 2 is made of special polyester non-woven fabric; the third stress dissipating layer 3 is made of special modified asphalt; the rock slice layer 4 is made of 8-10 mesh rock flakes, and the overall stress dissipating layer and cement Concrete pavement and asphalt concrete pavement must be firmly bonded. Since the first and third stress dissipating layers are made of special modified asphalt, the tensile str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com