High-efficiency spray washing device

A water washing device and high-efficiency technology, which is applied in the configuration of textile material processing equipment, spray/jet textile material processing, textile and papermaking, etc., can solve the problems of large equipment footprint, low wastewater utilization rate, and long process flow, etc. Achieve the effects of small equipment footprint, reduced water and sewage discharge, and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

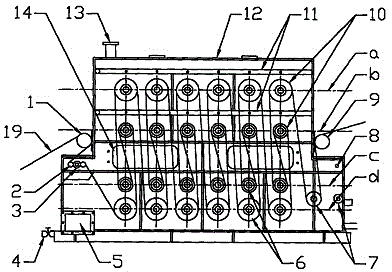

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

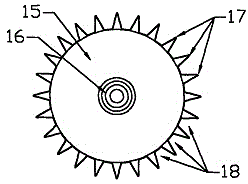

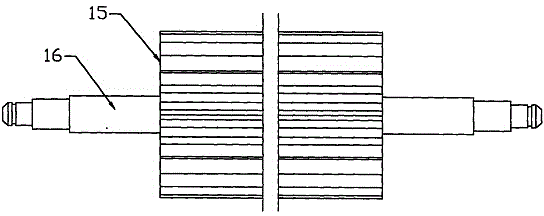

[0019] like figure 1 As shown, the high-efficiency spraying water washing device of the present invention, its basic concept is: set four layers of cloth guide roller layers a, b, c, d from top to bottom in the spray water tank 12, and each layer of cloth guide stick layer has number The same plural rows of parallel cloth guide rollers correspond one by one up and down; the first cloth guide layer a and the second cloth guide layer b are respectively provided with spray pipes 11, the third cloth guide layer c, the fourth cloth guide layer The cloth roller layer d is located at the position below the water surface of the conventional water storage capacity of the spray water tank 12; figure 2 , 3 ), which includes a cylindrical stick body 15 and tooth-shaped ribs 17 uniformly distributed on the surface of the stick body 15 in the axial direction.

[0020] As a further i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com