Novel dry-process fiber fabric forming equipment

A molding equipment and fiber fabric technology, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of different directions of thrown out fibers, affecting the uniformity of fiber distribution and laying, and the easy re-adhesion of fibers, etc., to achieve The effect of high-quality web laying, improved utilization of raw materials, and uniform fiber dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The patent of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

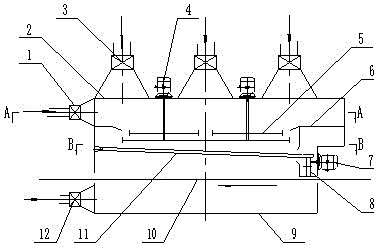

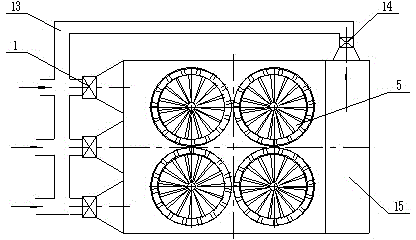

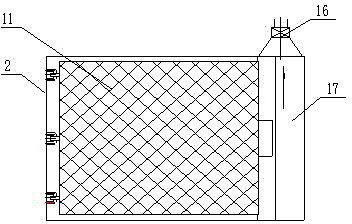

[0012] The invention provides a novel dry-laid fiber fabric forming equipment, such as figure 1 As shown, the molding equipment includes a molding box upper box (2), a molding box lower box (9), a screen (11) and a forming net (10). A feeding fan (1) is installed on the side wall of the upper box body (2) of the molding box, and a top pressure fan (3) and a fan motor (4) are installed on the top, and the fan motor (4) drives the upper box body of the molding box The dispersing fan (5) in (2) rotates, and a partition (6) is arranged in the upper box (2) of the forming box, and a screen (11) is provided on the lower side of the partition (6), and the screen (11) One end is hinged on the side wall of the upper box (2) of the molding box, and the other end is connected with the cam (8), which is driven by the vibrating screen motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com