Metal mask plate and organic electroluminescent display device manufactured by metal mask plate

A metal mask and image display technology, which is applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of unfavorable OLED display, limiting the width of OLED display frame, and large magnetic force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

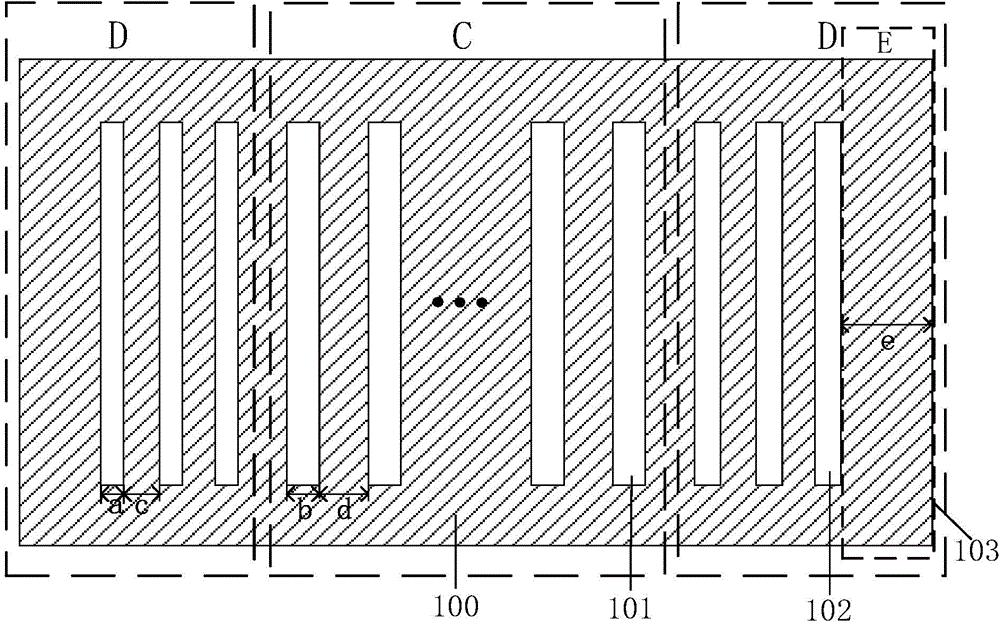

[0051] Such as Figure 2b As shown, the width b of the first strip slit 101 of the metal mask is 35 μm, the distance d between adjacent first strip slits 101 is 80.5 μm, and the width of the second strip slit 102 is a is 25 μm, the distance c between adjacent second strip-shaped slits 102 in the same second region D is 80.5 μm, and the width e of the side region E is less than 2.45 mm.

[0052] At this time, if the metal mask of this design is used for evaporation, the total width of the evaporated organic matter will be reduced by 60 μm compared to the original (because 6*(35-25)=60 μm), if the organic electroluminescent display is formed after packaging The frame of the device product will be reduced by 0.06mm.

example 2

[0054] Such as Figure 2dAs shown, the width b of the first strip slit 101 of the metal mask is 35 μm, the distance d between adjacent first strip slits 101 is 80.5 μm, and the width of the second strip slit 102 is a is less than 35 μm, the distance c between adjacent second strip-shaped slits 102 in the same second region D is less than 80.5 μm, and the width e of the side region E is less than 2.45 mm.

[0055] Such as Figure 3a with Figure 3b As shown, the metal mask of this design is combined with the magnetic spacer 104, and in the process of being attracted by the magnetic spacer 104 to move upward, it is assumed that three strip-like slits 101 are provided in each second region D. The second strip-shaped slits 102 parallel to each other, the area between the adjacent second strip-shaped slits 102 is R 1 , R 2 , R 3 , the dotted line is set as the central stress line of the area between the adjacent second strip-shaped slits 102 . for R 3 , the interaction force...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com