Online measurement system and method for geometric parameters of wheel set

A technology of geometric parameters and measurement system, applied in the direction of rim measurement/measurement, can solve the problems of low accuracy of base point position, low efficiency and accuracy, increase cost, etc., to avoid inaccurate position measurement of inner side and improve accuracy and the effect of improving precision and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

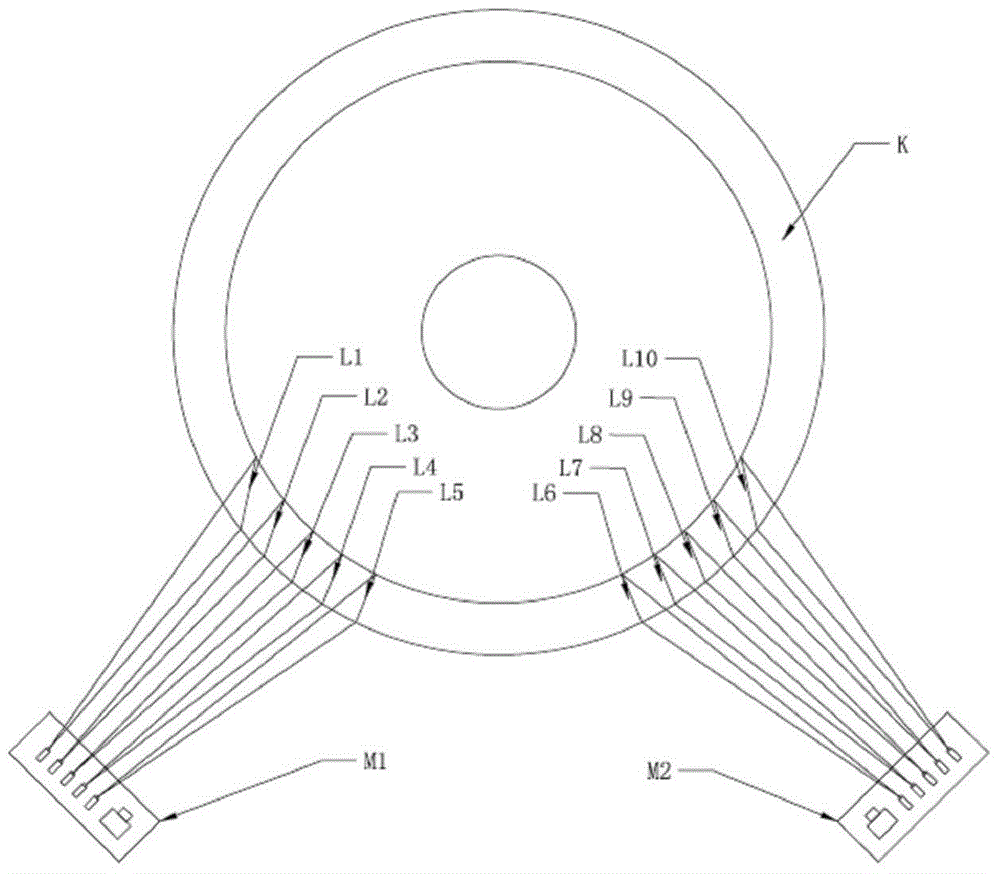

[0028] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

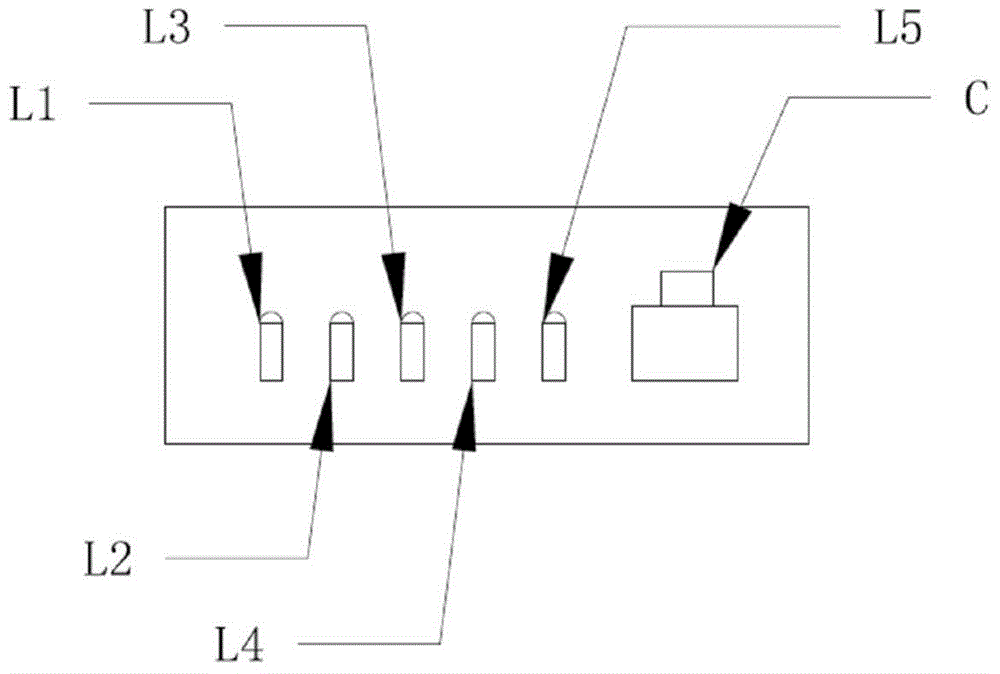

[0029] Take the online measurement system of wheel set geometric parameters based on the multi-line structured light sensor that can complete the measurement of the most basic complete unit as an example, and the first structured light sensor of each sensor group is a multi-line structured light sensor, the second structured light sensor The sensor is a single-wire structured light sensor as an example, and the technical solutions of the present invention are further described through the following embodiments.

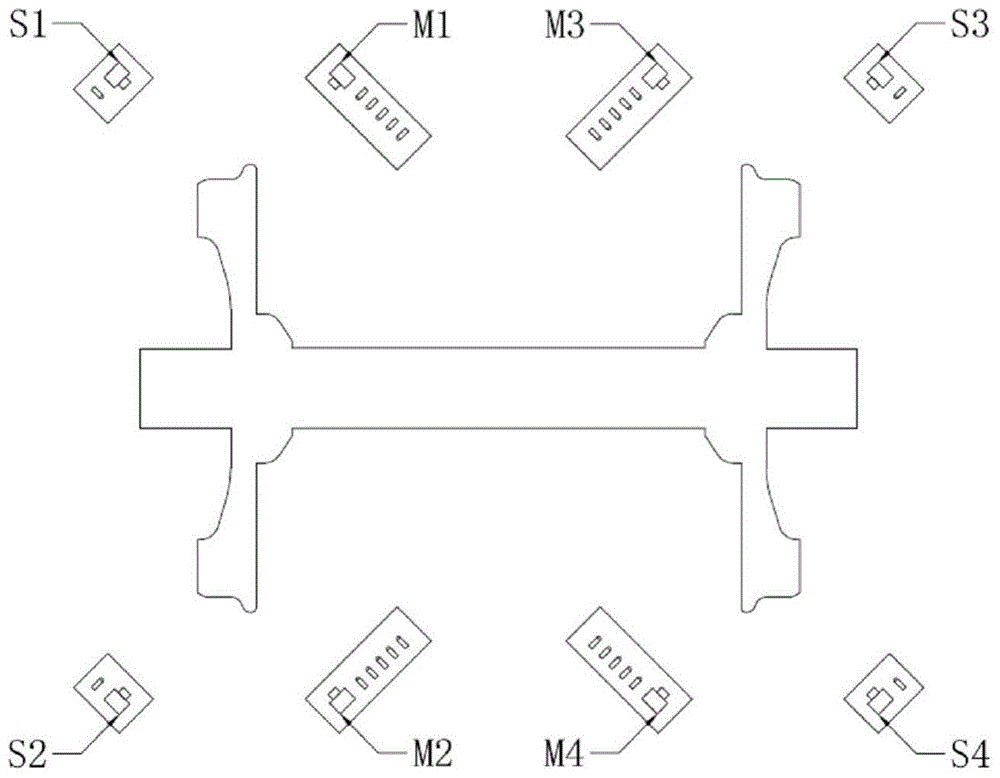

[0030] The system includes 4 multi-line structured light sensors (M1, M2, M3, M4) and 4 single-line structured light sensors (S1, S2, S3, S4) and other corresponding accessories, of which two multi-lines are arranged on the left and right sides of the wheel set Structured light sensor, two single-line struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com