Method and equipment for gluing ASA and PMMA alloy decorative films

A decorative film and gluing technology, which is applied to chemical instruments and methods, coatings, lamination devices, etc., can solve the problems of hard glue layer, unsuitable gluing, and no flexibility, so as to prevent deformation and maintain softness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

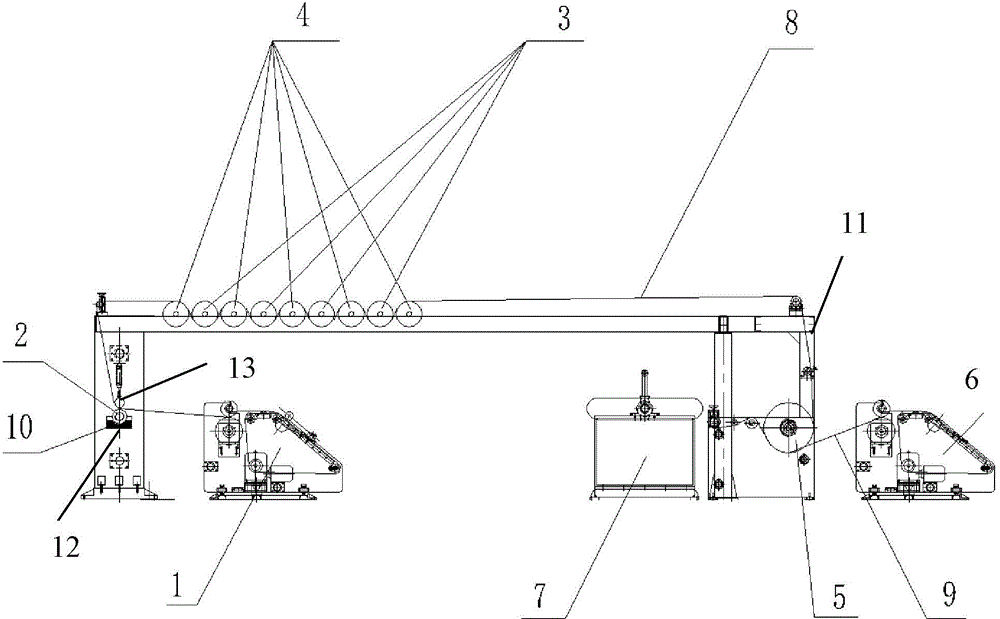

[0016] The gluing method and gluing equipment for ASA and PMMA alloy decorative films provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0017] The glue coating method for ASA and PMMA alloy decorative films provided by the present invention is to first coat a layer of primer glue on the back of the ASA and PMMA alloy decorative films as base materials, and then heat the primer glue and the base material respectively. After drying and cooling, the base coating glue is dried to form an adhesive layer, thereby making an ASA, PMMA alloy decorative film with an adhesive layer.

[0018] A layer of release paper is also attached on the adhesive layer.

[0019] The heating and drying temperature is 40-250 degrees.

[0020] The heating and drying method is contact heating; the cooling method is contact cooling, and heating drying and cooling are alternately performed.

[0021] like figure 1 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com