Method for monitoring bending life of steel wire rope of CNC (Computer Numerical Control) floor type boring and milling machine

A steel wire rope and floor boring technology, which is applied in the field of wire rope bending life monitoring of CNC floor boring and milling machines, can solve the problems of lack of accurate and reliable data in the selection and maintenance of steel wire ropes, the inability to count the number of bending times of steel wire ropes, and the overdue service of steel wire ropes. Accurate maintenance, improved overall safety, and guaranteed safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

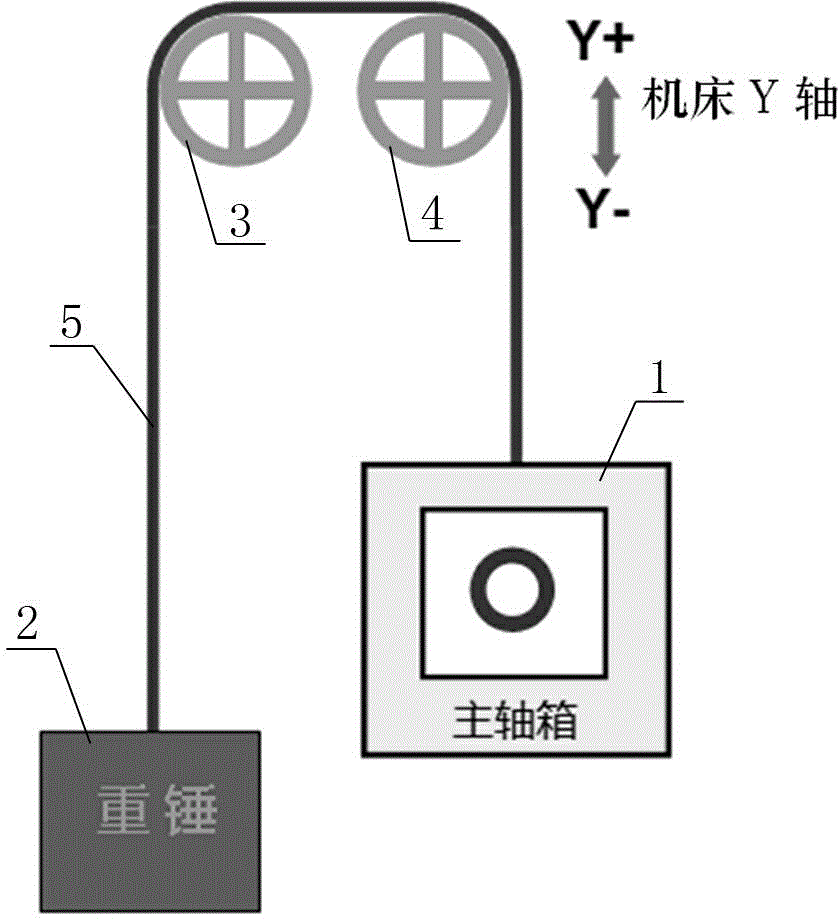

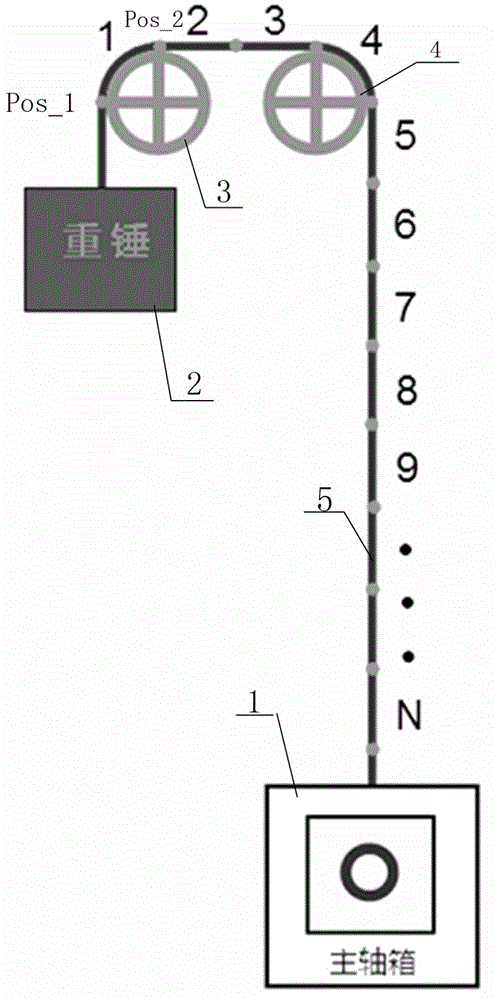

[0021] Such as figure 1 As shown, the schematic diagram of the structure of the spindle box in the CNC boring and milling machine is counterweighted by a steel wire rope, a fixed pulley and a weight. One end of the steel wire rope 5 is fixed to the spindle box 1, and the other end bypasses the first fixed pulley 3 After the second fixed pulley 4 is fixed with the weight 2, the headstock 1 is provided with a tool and a driving device that drives it to move along the Y-axis direction, and the weight 2 realizes the counterweight to the headstock 1, so that it Under the action, it is convenient to drive it to move along the Y-axis direction.

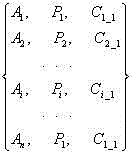

[0022] During the working process of the CNC boring and milling machine, the spindle box 1 will move up and down along the Y axis, so that the steel wire rope 5 will be bent on the first fixed pulley 3 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com