Support structure of glue-pumping device

A support structure and support plate technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of low work efficiency and achieve the effect of improving work efficiency and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

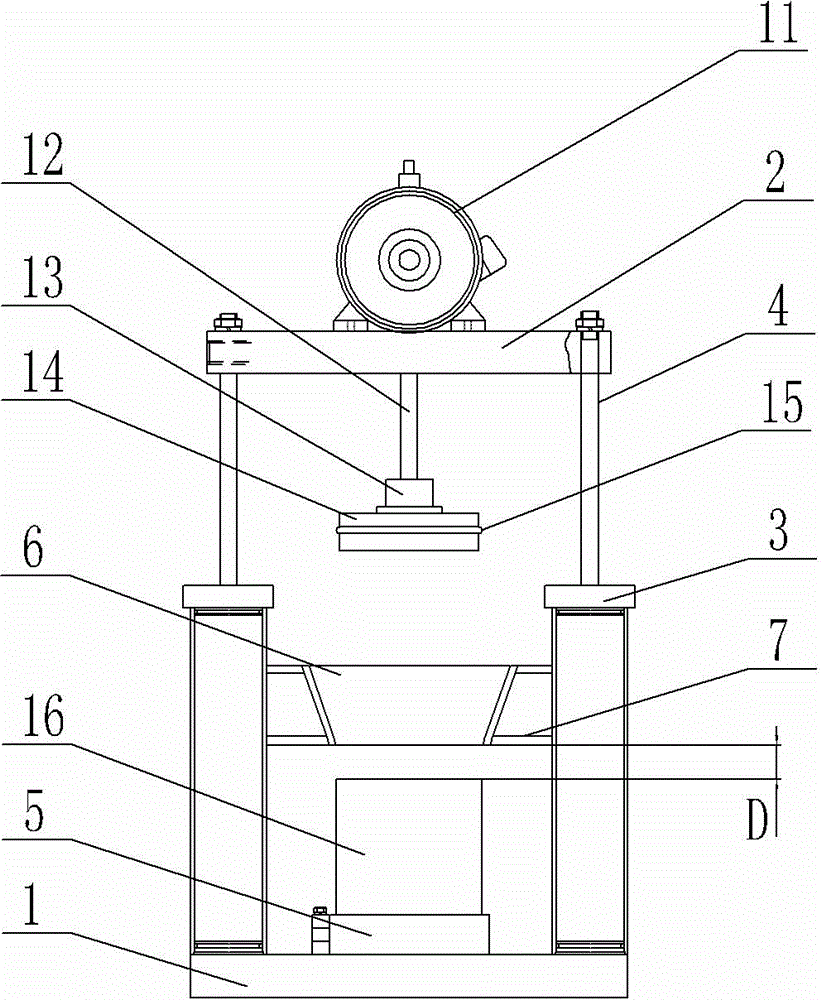

[0010] Such as figure 1 As shown, the supporting structure of the glue pumping device includes a base 1 and a support plate 2, the two ends of the base 1 are provided with a cylinder 31 and a cylinder 32, and the two ends of the support plate 2 are supported on the piston rods of the cylinder 31 and the cylinder 32 4. At the end, the motor 11 of the glue pumping device is fixed on the support plate 2, the positioning hoop 5 is installed on the base 1, and the guide hoop 6 is arranged above the positioning hoop 5. The heating of the positioning hoop 5, the guiding hoop 6 and the glue pumping device The disk 14 is coaxially distributed; the guide hoop 6 is an inverted cone shape, and the distance D between the bottom end surface of the guide hoop 6 and the upper end surface of the hot melt adhesive barrel 16 is 1.5 cm to 2 cm, and its inner diameter is the same as that of the hot melt adhesive barrel 16 The inner diameter is equal; the inner diameter of the positioning hoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com