Dispersing device of powder grinding equipment

A throwing device and grinding device technology, applied in the field of throwing devices, can solve problems such as high unit energy consumption, easy inhalation of operators, poor load adaptability, etc., and achieve the effect of uniform grinding particle size and narrow distribution range of powder particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

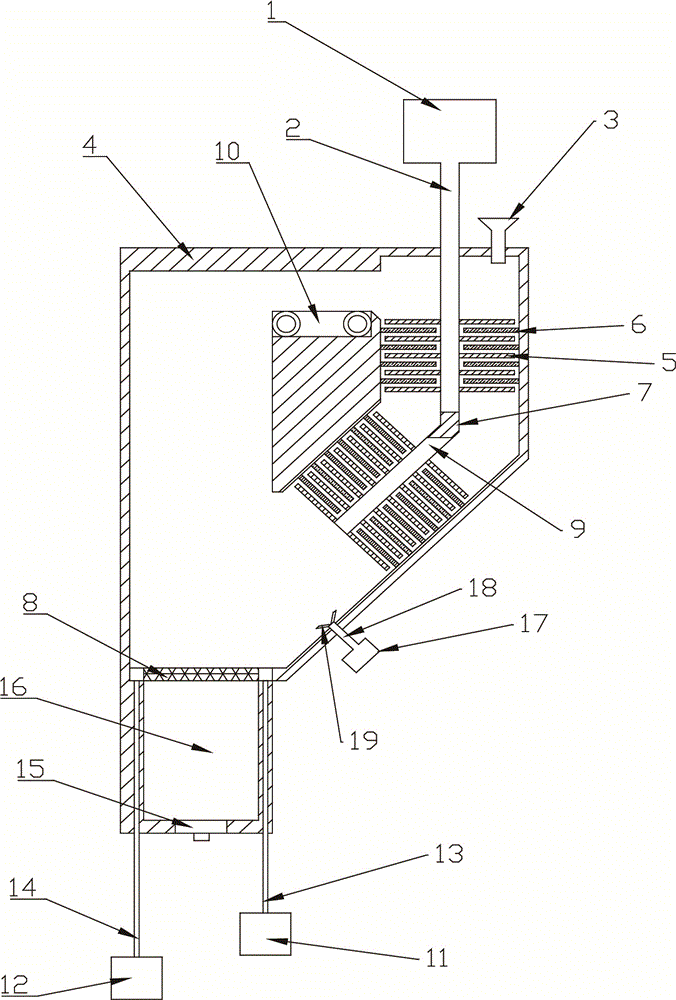

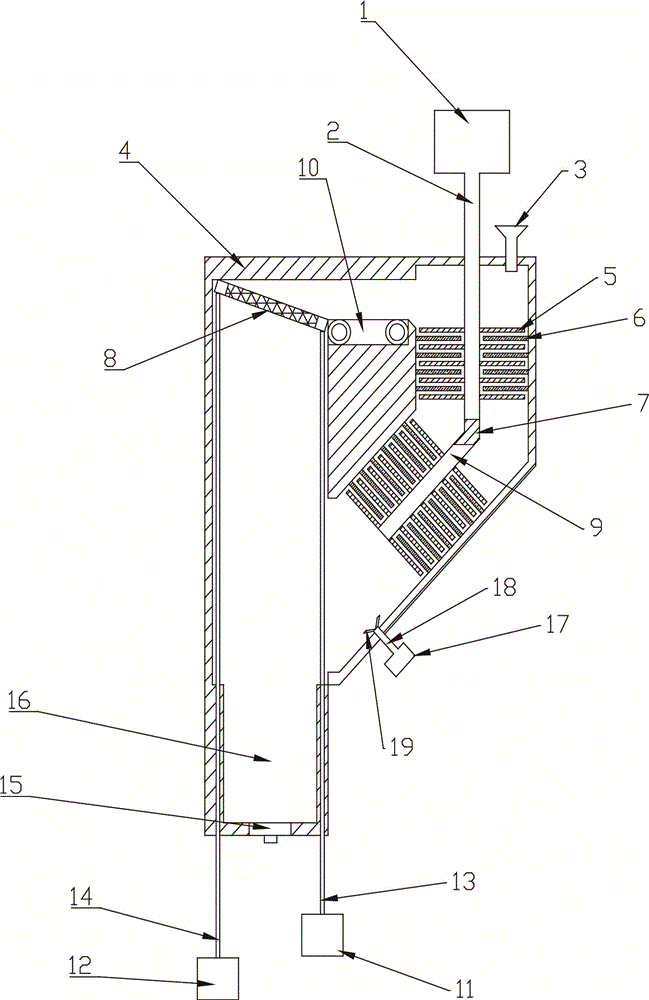

[0012] The technical solutions of the present invention will be further described below with reference to the drawings and embodiments.

[0013] See Figure 1 to Figure 2 , a throwing device for powder grinding equipment, the throwing device includes a second motor 17, the second motor 17 is connected to a rotating shaft 18, and the rotating shaft 18 is provided with a throwing blade 19, which is ground by the grinding device When the powder goes down the slope, the throwing device can throw the powder onto the filter screen 8, so that the powder will not stick together when the slope falls, so that the powder sticks into blocks. When the lifting device rises, the first lifting plate 13 will block the entrance to the storage bin 16, so that the powder will accumulate at the entrance, and the scattering device can scatter these powders to prevent the powder from accumulating for a long time and condensing into piece.

[0014] In this embodiment, the powder grinding equipment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com