Viscoelastic system constructed by functional Gemini surfactants and preparation method of viscoelastic system

A surfactant and viscoelastic technology, applied in the field of viscoelastic surfactant solution, can solve the problems of high cost and high concentration of surfactant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: the synthesis of α-bromotetradecanoic acid methyl ester. Add tetradecanoic acid (150g, 0.6568mol) into a 500ml three-necked flask, melt at 65°C, slowly add thionyl chloride (106.6g, 0.821mol) dropwise under stirring, raise the temperature to 90°C after the dropwise addition, add A little elemental iodine was used as an initiator, and liquid bromine (131.2g, 0.821mol) dried by concentrated sulfuric acid was slowly added dropwise, stirred and refluxed for 12 hours, and the temperature was lowered to 65°C, and anhydrous methanol (52.6g, 1.64mol) was added dropwise with stirring. mol), reflux for 2-4 hours after the addition. After cooling, wash with water 3-4 times, then wash the organic layer with 50 ml of saturated sodium sulfite solution until neutral, and finally wash with water 3-4 times. The organic layer was dried overnight by adding anhydrous magnesium sulfate. After filtration, the crude product was distilled under reduced pressure to obtain α-brom...

Embodiment 2

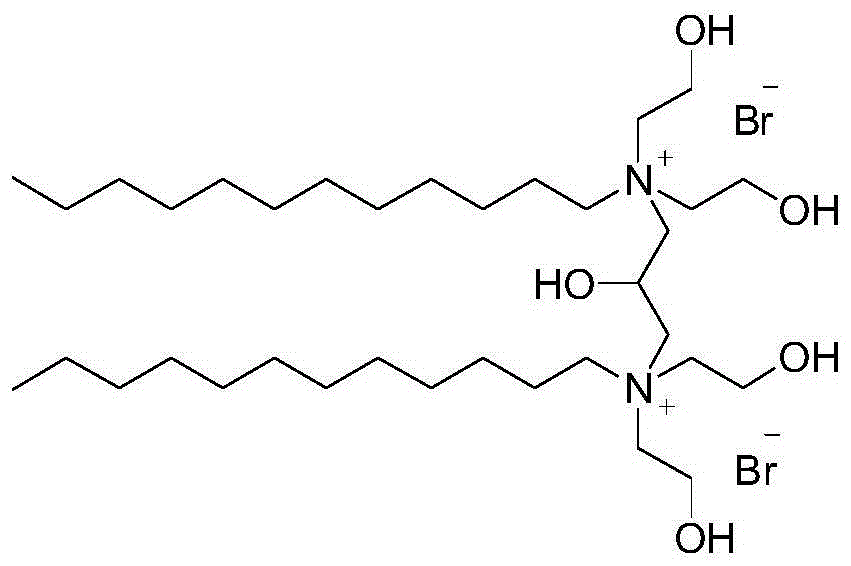

[0017] Embodiment 2: the synthesis of Gemini cationic surfactant. Mix 200 mL of absolute ethanol, 1-bromododecane (100 g, 0.4 mol), and diethanolamine (170 g, 1.62 mol), and react at 60° C. for 48 h. After cooling, sodium hydroxide (20 g, 0.5 mol) was added and stirring was continued for 1 h. After the ethanol was removed by rotary evaporation, 150 mL of distilled water and 100 mL of diethyl ether were added to the residue, and the system was separated into layers. The upper organic layer was separated, and the lower layer was extracted twice with diethyl ether. The extracts were combined and washed twice with distilled water. The ether solution was dried over anhydrous magnesium sulfate, filtered and removed by rotary evaporation of ether. The residue was distilled under reduced pressure to obtain N-dodecyldiethanolamine as a colorless viscous liquid (180°C / 5mmHg).

[0018] N-dodecyldiethanolamine (20g, 0.073mol), 1,3-dibromopropane (6.6g, 0.033mol) and 20mL of absolute e...

Embodiment 3

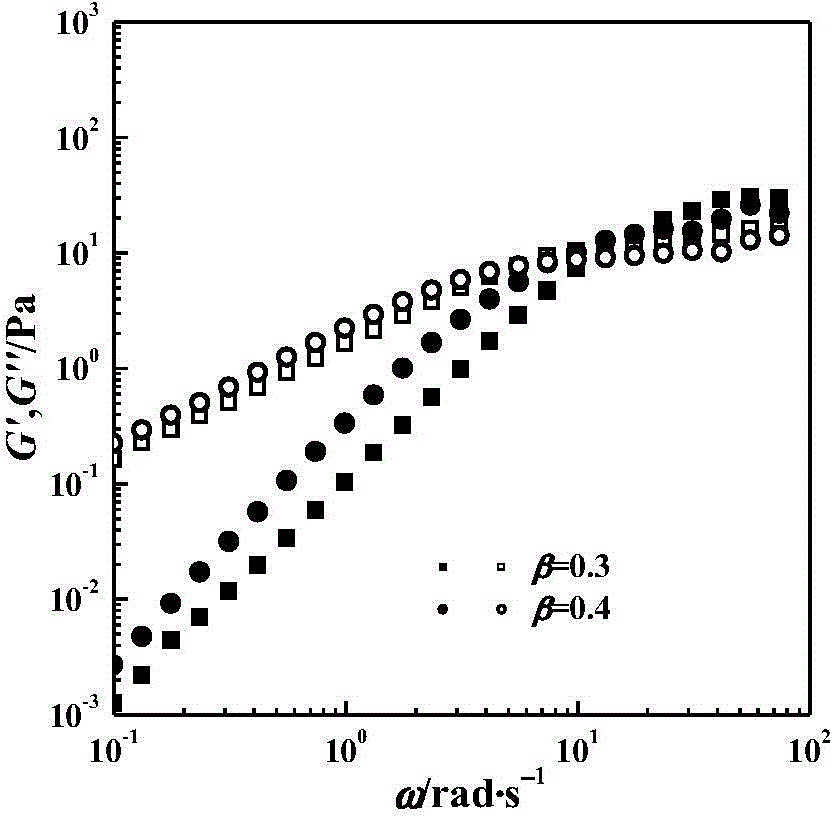

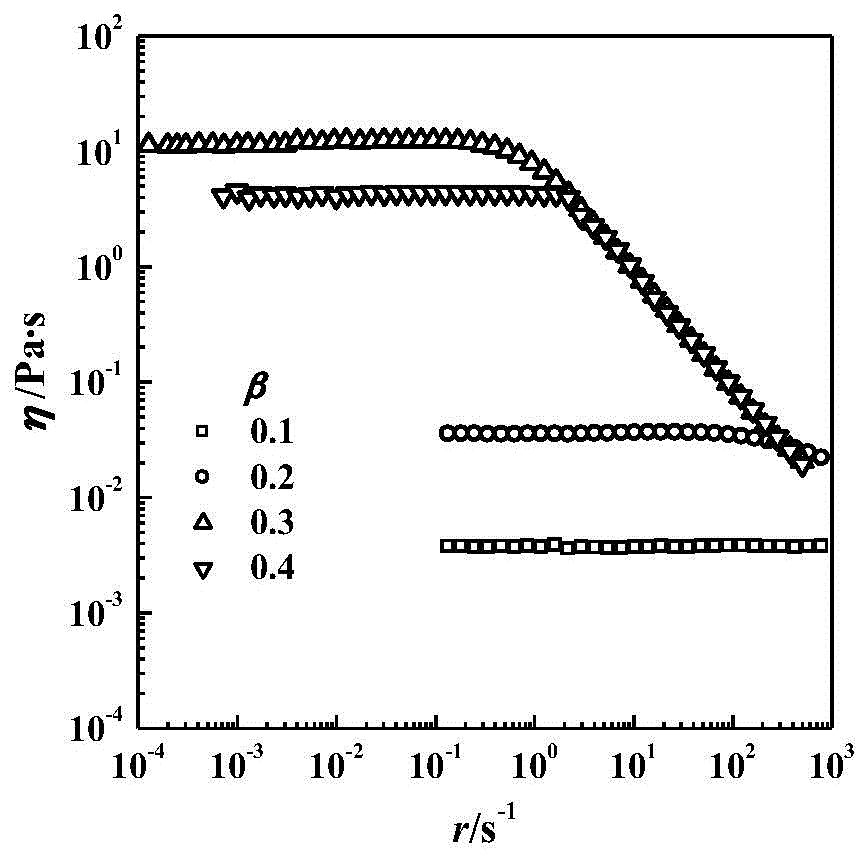

[0019] Embodiment 3: the preparation of viscoelastic surfactant solution. Prepare 5ml of Gemini cationic surfactant solution of 50mmol / L, and add appropriate amount of sodium dodecanoate, sodium myristate and sodium palmitate solid to it respectively to make Gemini cationic surfactant and sodium dodecanoate and sodium myristate The molar ratios of sodium palmate reached 1:0.1, 1:0.2, 1:0.3 and 1:0.4 respectively, and the molar ratios of Gemini cationic surfactant and sodium hexadecanoate reached 1:0.1, 1:0.2, 1:0.3, 1:0.4 and 1:0.5. After dissolving, a series of viscoelastic surfactant solutions are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com