Mop with humidity regulating device

A technology of humidity adjustment and mopping, which is applied in the fields of electronic information and sanitation cleaning, can solve the problems of unable to actively control humidity and reduce efficiency, and achieve the effect of reducing frequency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

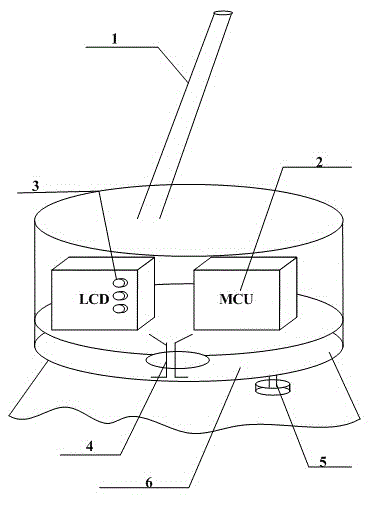

[0016] A mop with a humidity regulating device. It includes a mop shell 1, a microcontroller 2, a display and a battery 3, a valve 4, a humidity sensor 5, and a water tank 6. Microcontroller 2 is installed in the bottom right position of mop shell 1, the top of water tank 6. Microcontroller 2 is connected with display and battery 3 . Display and battery 3 are installed in the lower left position of mop shell 1. The valve 4 is installed at the bottom position of the water tank 6 . The valve 4 is connected with the display and the battery 3 . Humidity sensor 5 is connected in the bottom right of water tank 6. The humidity sensor 5 is connected with the microcontroller 2 . Water tank 6 is installed on the bottom of mop shell 1.

[0017] The water tank of the present invention has a larger volume and can store more water, so the humidity can be effectively adjusted during use, and the times of washing can be reduced. And because of the humidity sensor, it can accurately che...

Embodiment 2

[0019] The utility model relates to a mop with a humidity regulating device, the bottom water tank and the shell adopt a cylindrical structure; the bottom decontamination part adopts cloth strips. The cylindrical structure is designed to maximize the capacity while saving materials; while the cloth strip adopts the traditional design, which is economical, practical and easy to promote.

[0020] In actual use, install the battery on the present invention, set the desired humidity through the screen and the buttons next to it, and then fill the water tank with water. Then the microprocessor starts to control the valve at the bottom of the water tank to discharge a certain amount of water. When the data of the humidity sensor is transmitted to the microcontroller, the negative feedback adjustment is carried out, so as to control the humidity of the mop more accurately.

[0021] In this way, users can set the humidity they want through the buttons and the screen, and have substan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com