Method for machining perforated structure form luneberg lens

A hole-opening structure and Lumber lens technology, applied in the direction of electrical components, antennas, etc., can solve the problems that the processing technology cannot meet the requirements, the hole positioning and processing are difficult, and the electrical performance has a huge impact, so that the production environment is easy to realize, The effect of stable and reliable performance and low price and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0028] A processing method of a Lumberg lens antenna in the form of an aperture structure, comprising the following steps:

[0029] S1. Through electromagnetic software simulation, design parameters such as the diameter of the Lunberg lens, the number of layers along the radial direction, the number of holes in each layer, and the shape of the holes;

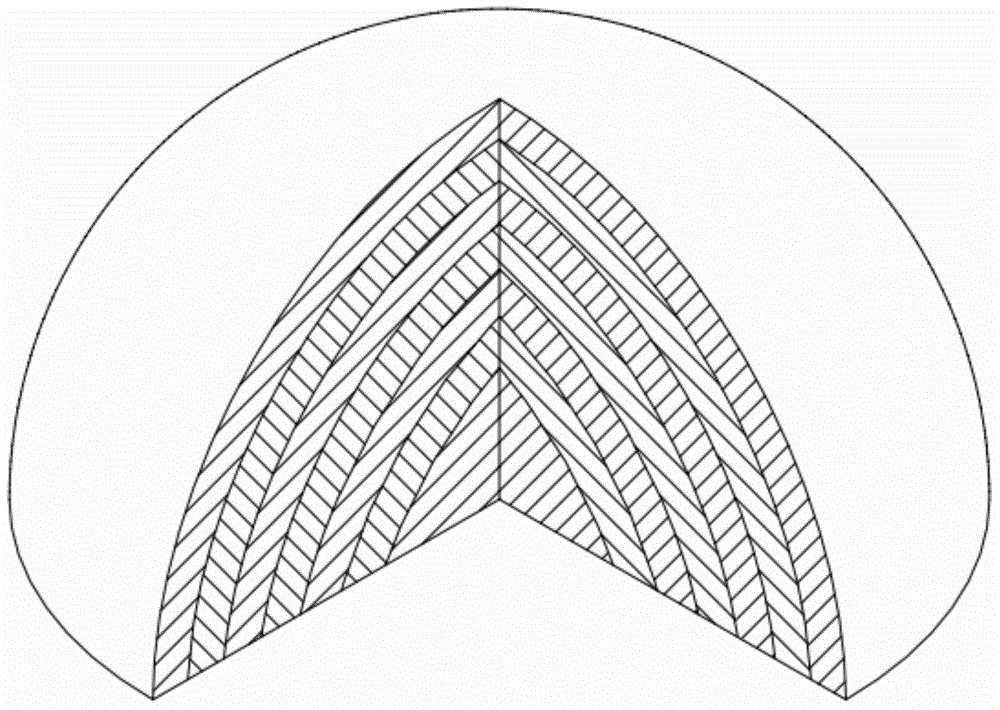

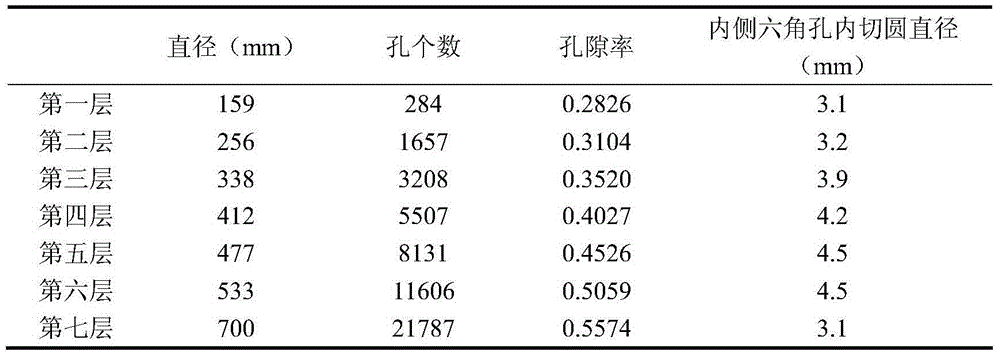

[0030] Example The simulation design is completed by the electromagnetic software CST, using polystyrene material, its size is a hemisphere with a diameter of 700mm, and it is divided into seven layers along the radial direction. The number of openings in each layer is shown in Table 1, and the openings are hexagonal structures. , the diameter of the inscribed circle of the hexagonal hole on the outer side of each layer is 5.2mm, and the diameter of the inscribed circle of the inner hexag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com