Magnetron

一种磁控管、管接头的技术,应用在磁控管领域,能够解决浪费多、削除的材料多、紧固部件116插入困难等问题,达到减少浪费、触及良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

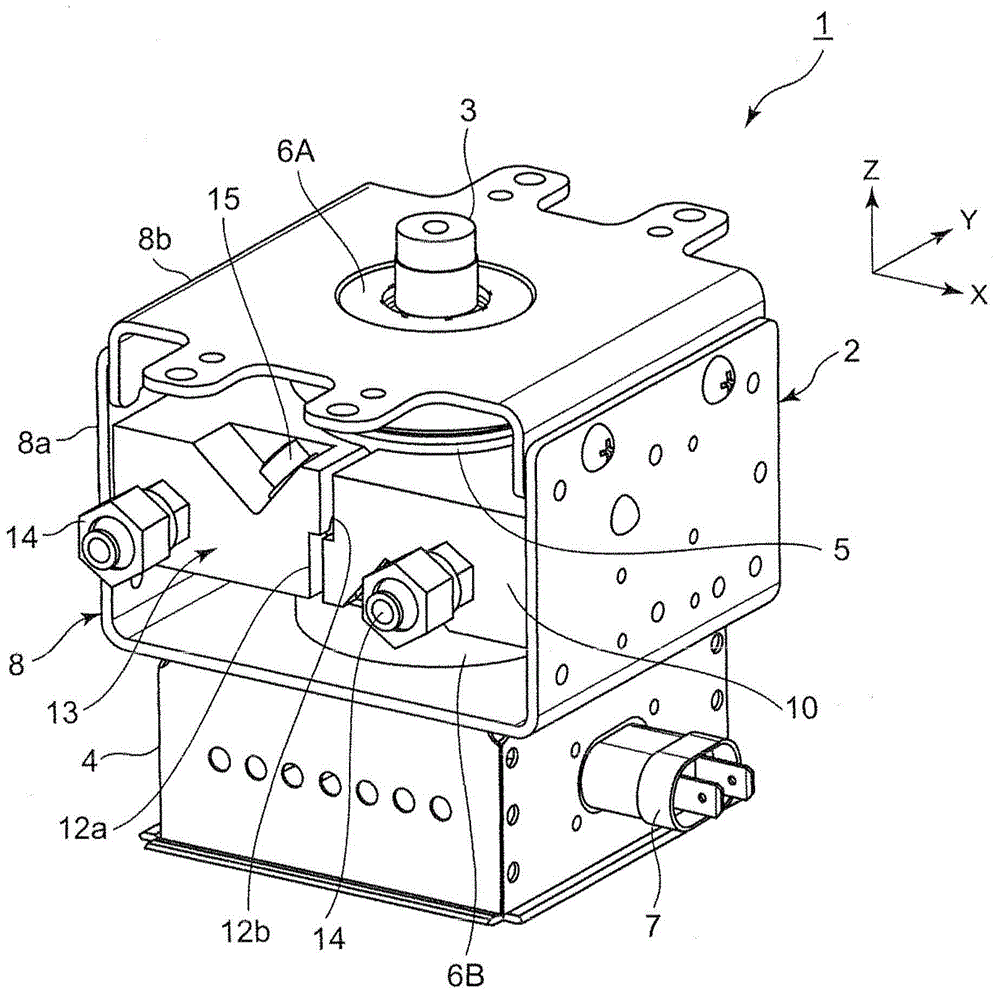

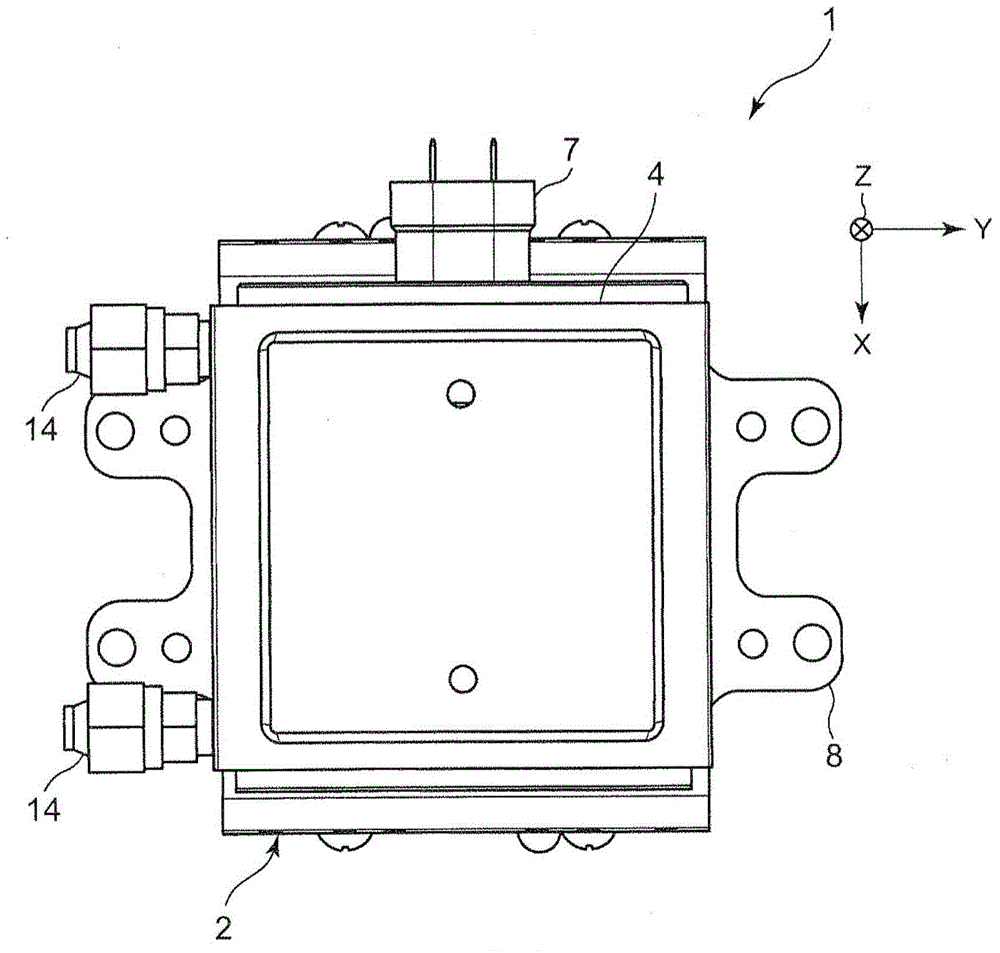

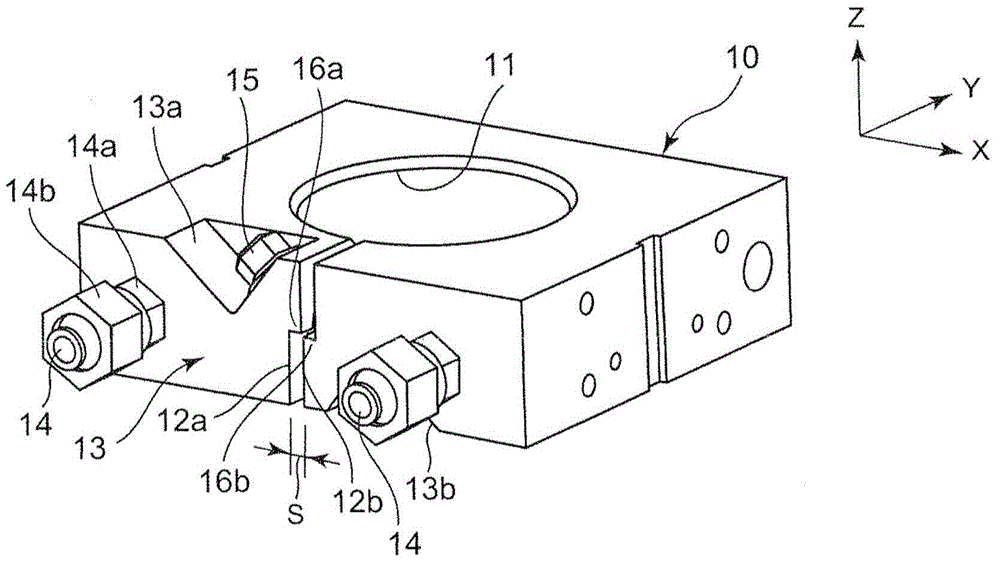

[0048] The magnetron according to the first aspect of the invention includes: an anode cylinder; and a cooling block, which is an integral part, has an annular shape in which both ends of an annular continuous portion face each other, and tightly surrounds the anode cylinder. It is fixed on the outer peripheral surface of the anode cylinder, and there is a cooling liquid circulation channel inside to cool the anode cylinder; the fastening parts are respectively engaged with the opposite ends of the cooling block, and the two ends are reduced by fastening. The distance between the ends makes the inner peripheral surface of the cooling block pressed against the outer peripheral surface of the anode cylinder; and a pair of pipe joints, which are connected to the opposite ends of the cooling block in a manner communicated with the circulation channel of the cooling liquid The adjacent parts are respectively connected, and the fastening member is arranged between a pair of pipe join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com