A solid electrolyte aluminum electrolytic capacitor and its manufacturing method

A technology of aluminum electrolytic capacitors and solid electrolytes, applied in solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of increased resistance of conductive polymers, impossibility of immersion or immersion, and low performance, so as to improve the lead-out rate, Improve the withstand voltage value and improve the effect of electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] The conductive polymer used in the dispersion A in this embodiment is poly-3,4-ethylenedioxythiophene, and its particle size is about 40-80 nm, preferably 60 nm. The capacitor specification is 200V100μF, and the size is Φ16*26mm. The manufacturing method of this capacitor is:

[0109] (1) JCC anode foil (manufactured by Japan Accumulator Industry Co., Ltd.), whose model is HGF110J16-365VF-1.33μF, with a width of 17mm and a length of 491mm; Nanofoil cathode foil, whose model is NF3000, with a width of 17mm and a length of 521mm ; Electrolytic paper Asahi Kasel ADS040060, width 20mm. The anode foil and the cathode foil are wound together into a core package through electrolytic paper, the anode of the core package is welded on the iron bar, the core package is immersed in the chemical solution, and a voltage of 365V is applied according to the voltage of the positive foil in the phosphoric acid system chemical solution. Formation for 20 minutes; after formation, soak th...

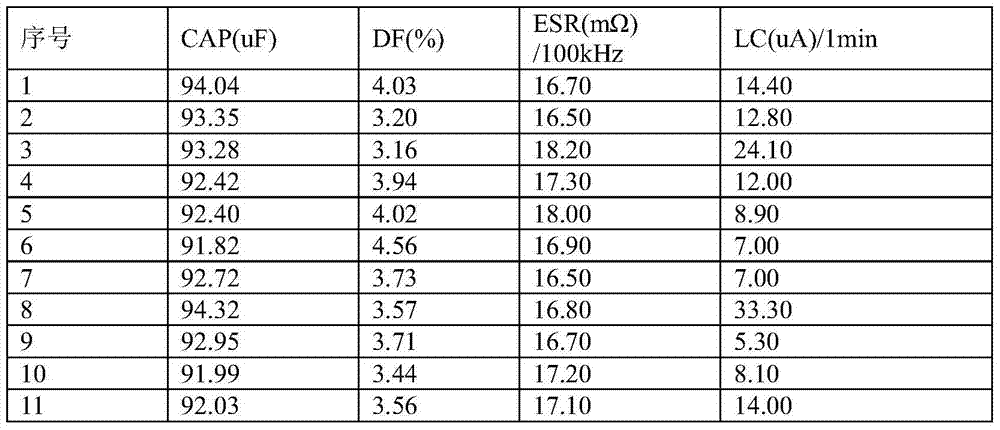

Embodiment 2

[0120] Similar to Example 1, 20 capacitors were manufactured and analyzed. The capacitor specification was 200V100μF, and the size was Φ16*26mm. The difference was that step (3) became: keep the core pack in the dispersion A, and pressurize it with compressed air. to 0.5MPa, the impregnation time is 5min, and the other steps and their order remain unchanged; the analysis results are shown in Table 2.

[0121] Table 2 is the performance test of the capacitor that embodiment 2 makes

[0122]

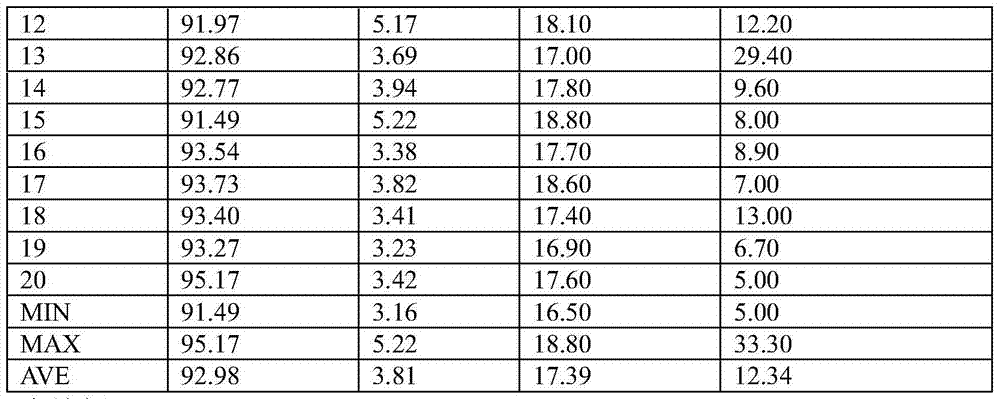

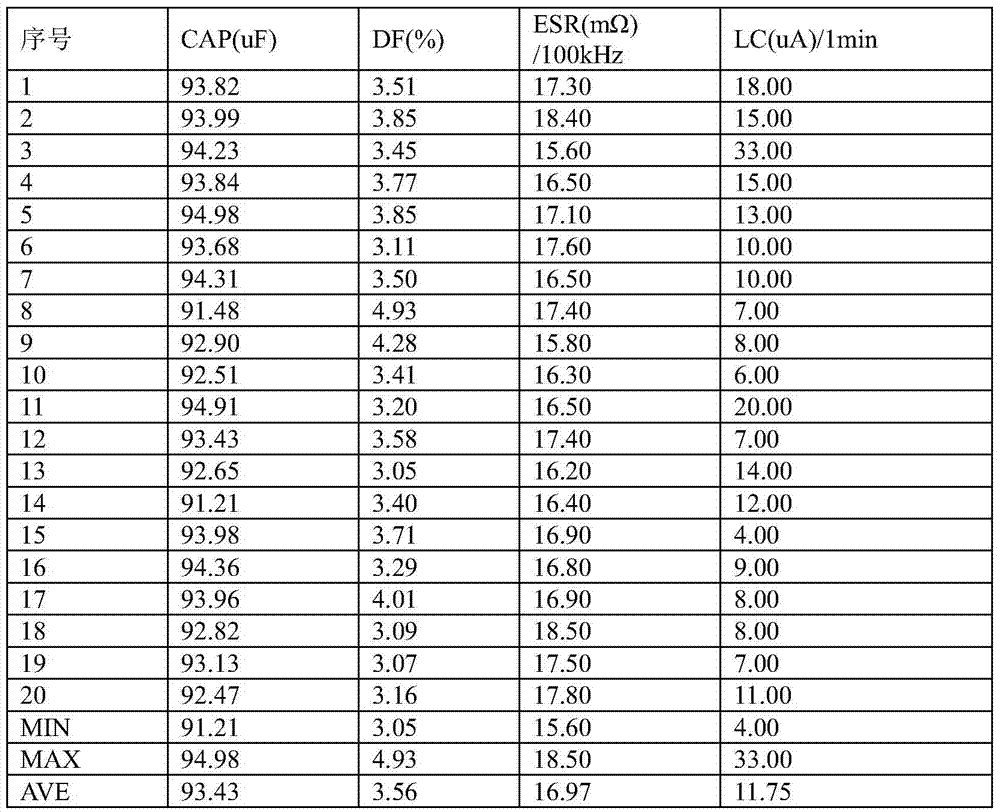

Embodiment 3

[0124] Similar to Example 1, 20 capacitors were manufactured and analyzed. The capacitor specification was 200V100μF, and the size was Φ16*26mm. The difference was that an atmospheric pressure impregnation step was added between steps (3) and (4). The atmospheric pressure impregnation step specifically For: keep the core package in the dispersion A, break the vacuum to normal pressure, and impregnate for 5 minutes; other steps remain unchanged, and the analysis results are shown in Table 3.

[0125] Table 3 is the performance test of the capacitor that embodiment 3 makes

[0126]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com