Method for predicting density and particle size distribution of particles in fluidized bed based on computational fluid mechanics

A computational fluid dynamics, prediction method technology, applied in particle and sedimentation analysis, particle size analysis, measuring devices, etc., can solve the problem of inability to accurately obtain the particle density and particle size distribution in the fluidized bed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

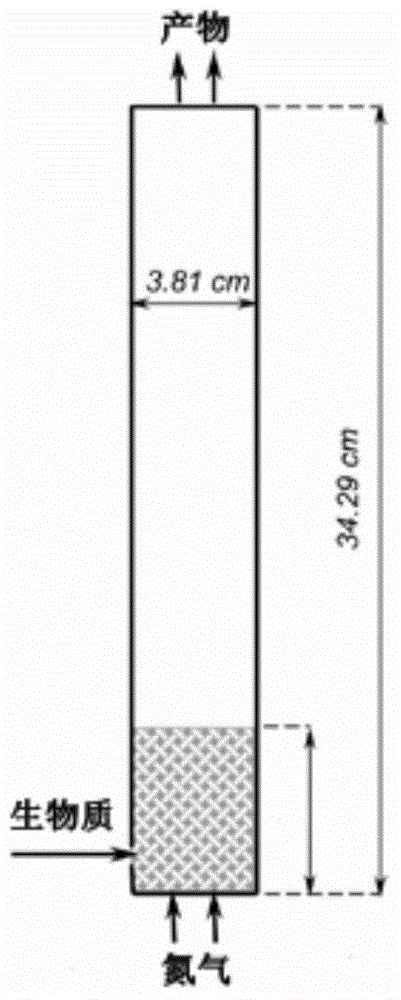

Method used

Image

Examples

Embodiment 1

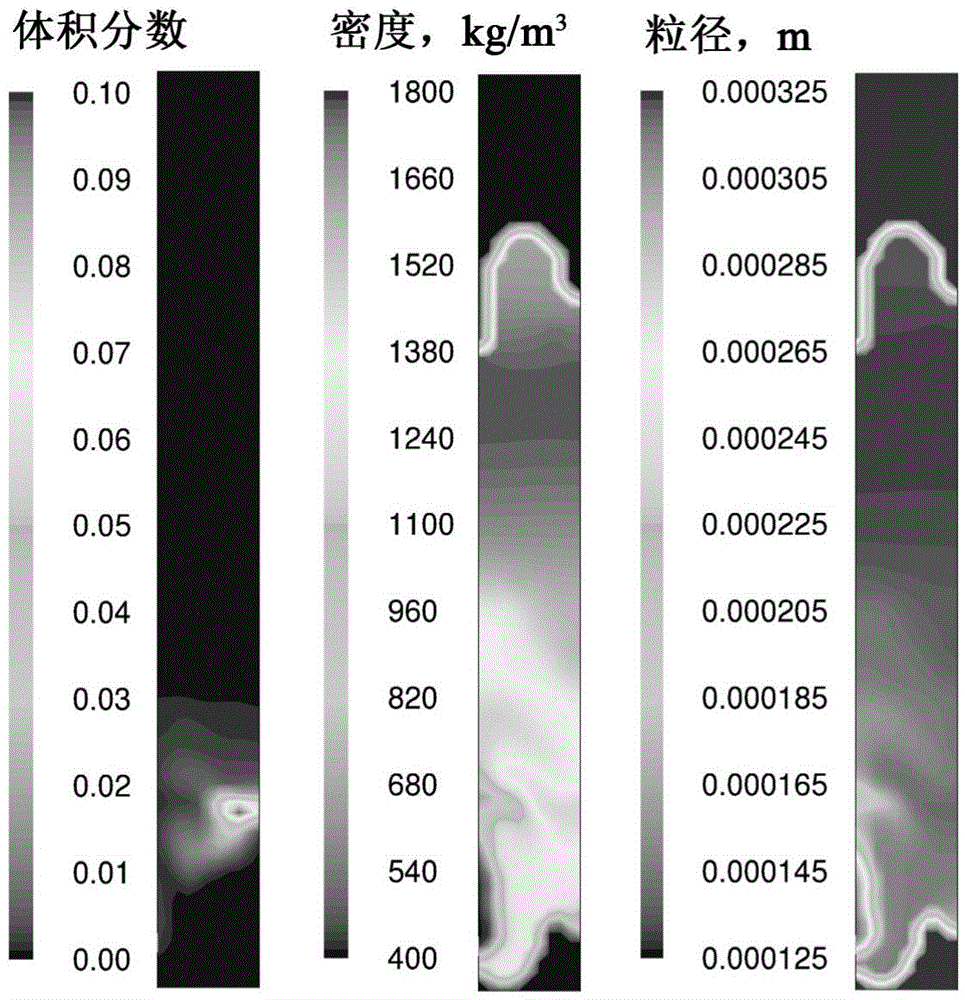

[0246] If the density and particle size change simultaneously during the rapid pyrolysis of biomass, the following mathematical model can be used to describe the particle size and density variation of the particle phase:

[0247] Mathematical model of particle phase density change:

[0248] ρ = 1 Y A ρ A + Y C ρ C

[0249] Mathematical model of particle size change in particle phase:

[0250] d p = ( 1 - ρ C - ρ ...

Embodiment 2

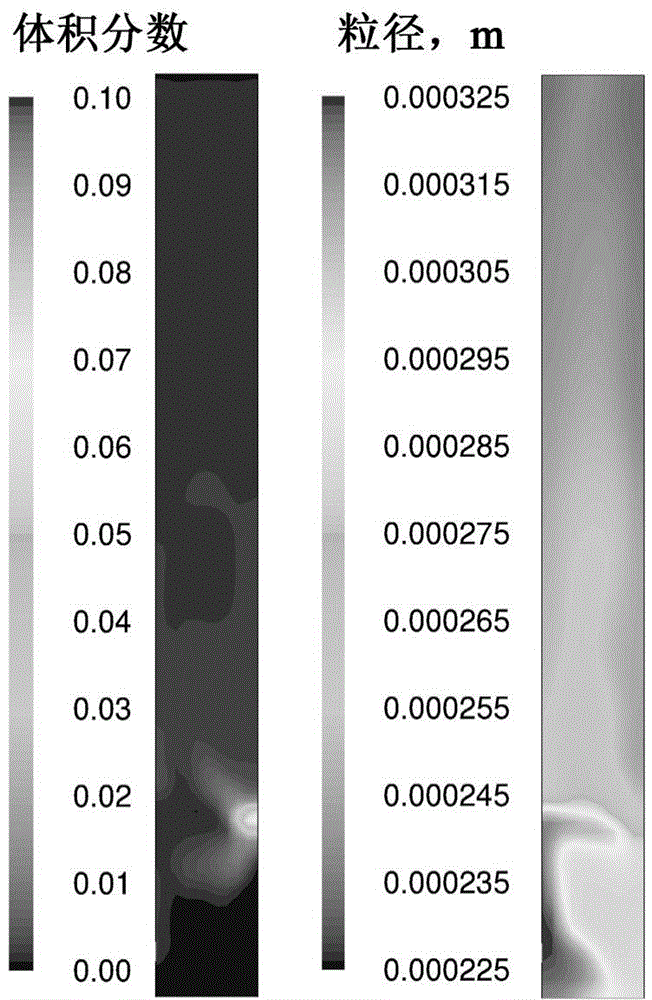

[0253] If only the particle size changes during the rapid pyrolysis of biomass, the following mathematical model can be used to describe the particle size and density variation of the particle phase:

[0254] Mathematical model of particle phase density:

[0255] ρ=ρ A = ρ C

[0256] Mathematical model of particle size change in particle phase:

[0257] d p = ( 1 - ( 1 - a ) ( 1 - Y A ) 1 - Y A ...

Embodiment 3

[0260] If only the density changes during the rapid pyrolysis of biomass, the following mathematical model can be used to describe the particle size and density changes of the particle phase:

[0261] Particle phase particle size mathematical model:

[0262] d p = d p0

[0263] Mathematical model of particle phase density change:

[0264] ρ C =aρ A

[0265] ρ = 1 Y A ρ A + Y C ρ C

[0266] Keep the particle size of the particle phase unchanged at 325 μm, and set the coke density ρ C =aρ A =108kg / m 3 In the process of numerical simulation, the density is corrected in real time according to the mathematical model of particle phase density ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com