A Method of Fault Diagnosis of Rolling Bearings Based on LCD‑MF

A rolling bearing and fault diagnosis technology, applied in mechanical bearing testing, special data processing applications, instruments, etc., can solve problems such as lack of robustness, poor classification effect of different fault degrees, lack of adaptability to changing working conditions, etc., to improve judgment The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

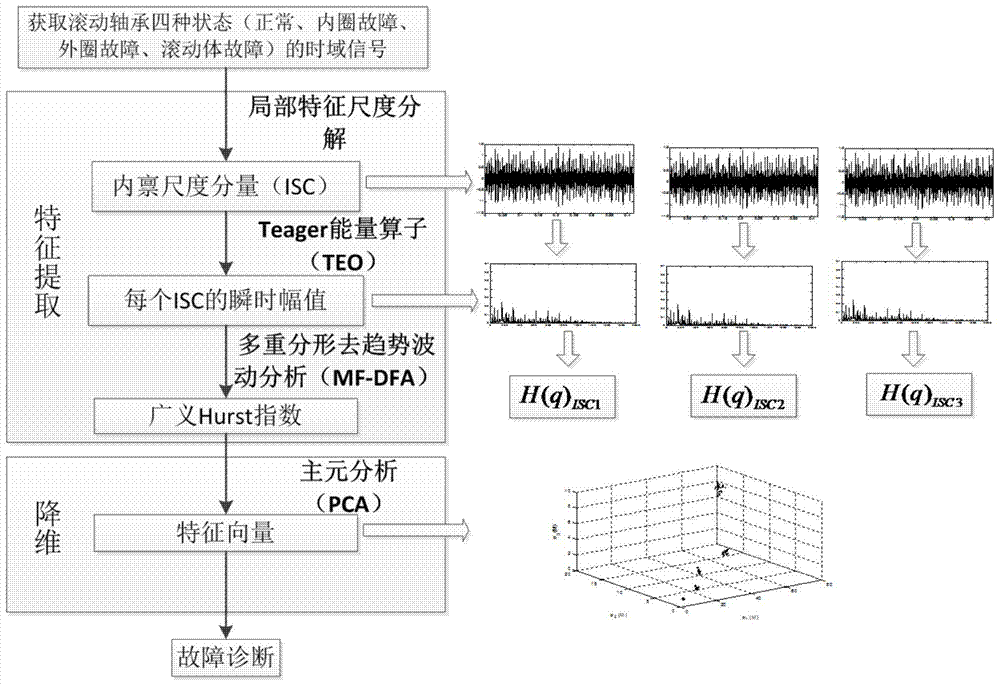

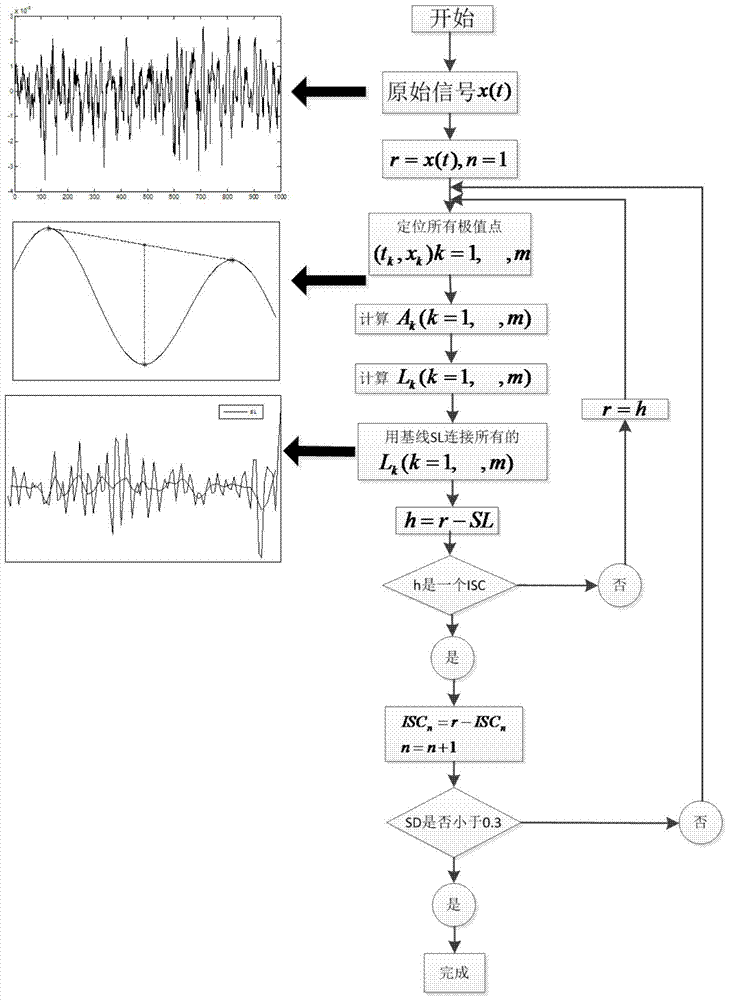

Method used

Image

Examples

Embodiment

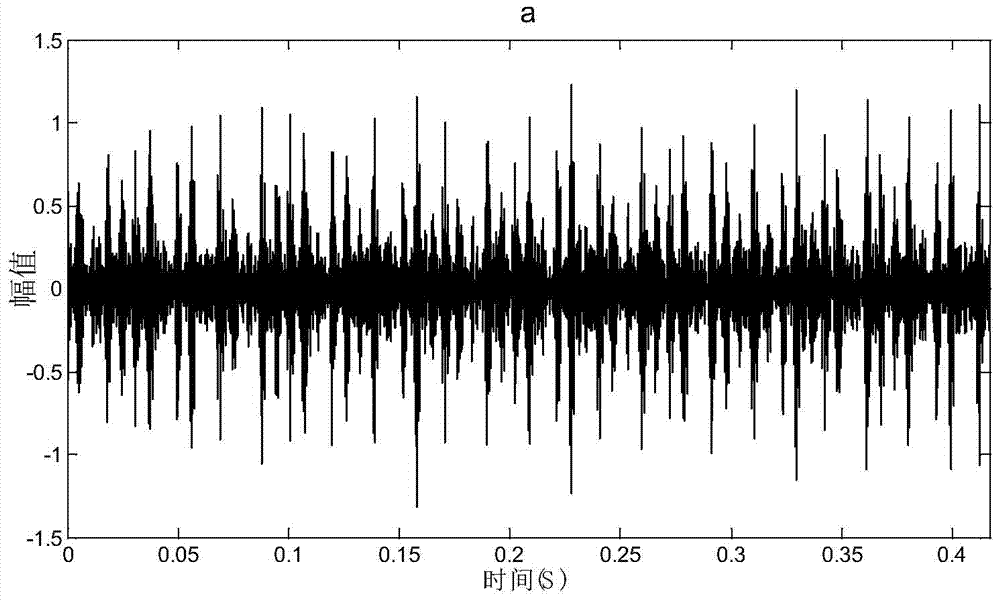

[0092] This example uses the experimental data of 6205-2RS deep groove ball bearings for verification. The outer diameter of the bearing is 39.04mm, the thickness is 12mm, the pitch diameter is 28.5mm, the diameter of the rolling elements is 7.94mm, and the number of rolling elements is 9. The angle is 0°. The bearing test consists of a motor with a power of 1.5kW, a torque sensor / encoder, a dynamometer and an electrical control device. The motor drives the input shaft, and the output shaft drives the load.

[0093] The sample signals collected during the normal state of the rolling bearing, the inner ring fault, the outer ring fault, and the rolling element fault are respectively used to detect and verify the rolling bearing fault diagnosis method based on local characteristic scale decomposition and multi-fractal detrending fluctuation analysis of the present invention. The specific steps are as follows:

[0094] Step 1. In the running state of the rolling bearing, collect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com