Metal smelting connecting rod stirring mechanism

A technology of stirring mechanism and connecting rod, which is applied in the field of mechanism for stirring molten metal, which can solve the problems that the stirring force and speed are difficult to control and affect metal smelting, etc., and achieve the effects of easy stirring control, reduced influence, and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

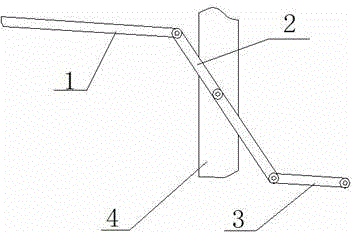

[0014] like figure 1 As shown, the connecting rod stirring mechanism for metal smelting includes a stirring shaft 1, a connecting rod A2, a connecting rod B3, and a base 4. The stirring shaft 1 is hinged to the connecting rod A2, and the other end of the connecting rod A2 is connected to the connecting rod B3 Connected by a hinge, the middle end of which is hinged on the base 4, the connecting rod B3 is connected with an external power source, and the movement mode of the external power source is rotational motion.

[0015] The length of the connecting rod B3 is less than the length of the connecting rod A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com