Anti-falling heat dissipation brake pad

A brake pad and anti-falling technology, which is applied to friction linings, slack adjusters, mechanical equipment, etc., can solve the problems of friction pads that cannot dissipate heat quickly, low braking efficiency, and small friction coefficient, so as to reduce temperature, Excellent heat dissipation performance and strong shear force resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below, the technical solution of the present invention will be described in detail through specific examples.

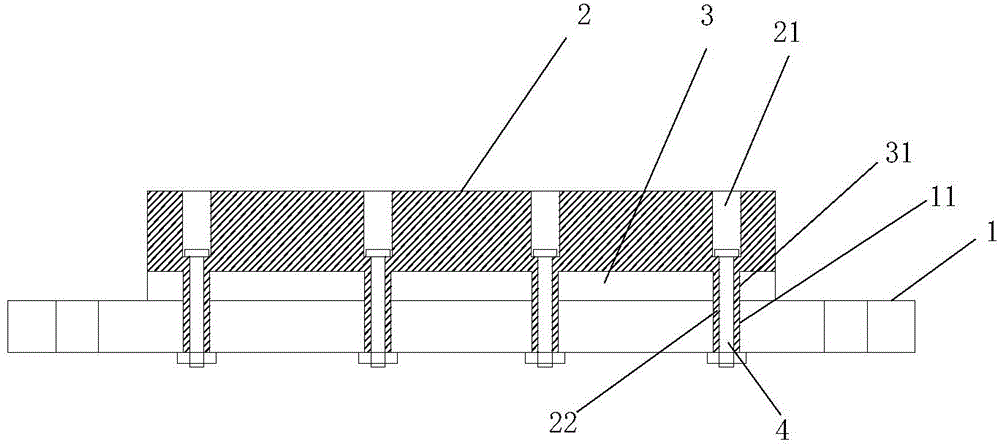

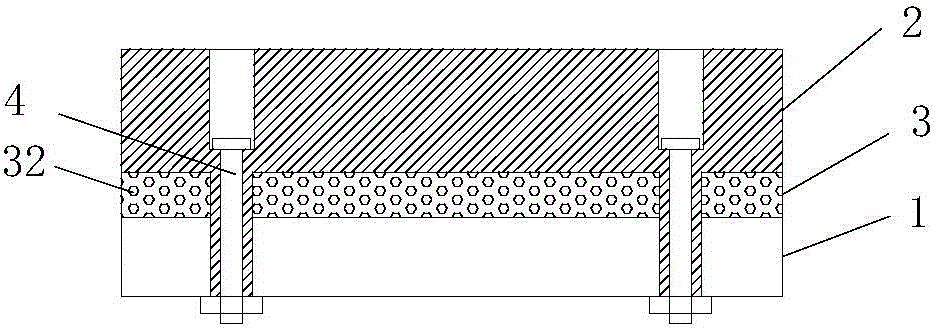

[0012] like Figure 1-2 as shown, figure 1 It is a structural schematic diagram of an anti-falling off heat dissipation brake pad proposed by the present invention; it is a cross-sectional view of a kind of anti-fall off heat dissipation brake pad proposed by the present invention.

[0013] refer to Figure 1-2 , an anti-falling heat dissipation brake pad proposed by an embodiment of the present invention includes: a steel back 1 , a friction plate 2 and a heat dissipation pad 3 arranged between the steel back 1 and the friction plate 2 .

[0014] Among them, the steel back 1 is provided with a plurality of first through holes 11, and the inner peripheral surface of the first through holes 11 is provided with tooth grooves, and the tooth grooves are arranged to strengthen the protrusion 22 on the friction plate 2 and the first through hole 11. The frictiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com