A rodless oil production device driven by a permanent magnet linear motor in the well

A permanent magnet linear motor and rodless oil production technology, which is applied in the direction of machines/engines, production fluids, earthwork drilling and production, etc., can solve the problems of increased crude oil production costs, increased maintenance workload, and reduced efficiency, so as to reduce operational safety risk, solve the eccentric wear of the rod tube, and eliminate the effect of stroke loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

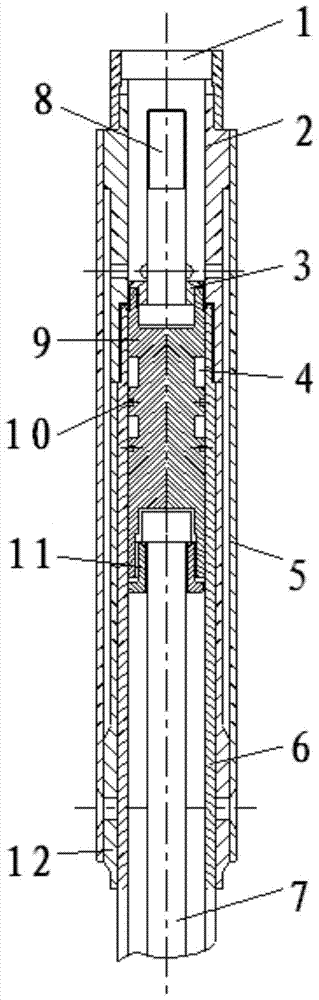

[0015] Taking a rodless oil production device driven by a downhole permanent magnet linear motor as an example, the present invention will be described in detail.

[0016] refer to figure 1 , the plunger 1 of the pull-down pump is connected to the pull rod of the motor through a conversion joint 8 with pins, the lower outer pipe of the pull-down pump is connected to the front piston collar 2 of the motor, the upper collar of the pull-down pump is connected to the tail end of the oil pipe, and the oil pipe, pull-down The pump and the downhole linear motor are lowered into the well to a predetermined depth.

[0017] The front sand control piston 9 is connected with the connecting shaft 7 by the upper piston nut 3 and the lower piston nut 11 at both ends, and the front sand control piston 9 is equipped with a sand control packing 4 and a dynamic seal 10, which jointly play a role in sealing the motor.

[0018] The front piston tube 6 is covered with a guide tube 5, which is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com