Production method of composite wall brick

A production method and composite technology, applied in botany equipment and methods, container cultivation, gardening, etc., can solve the problems of lack of visual beauty, messy overall structure, water seepage or leakage, etc., and achieve the goal of simplifying maintenance procedures and reducing operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

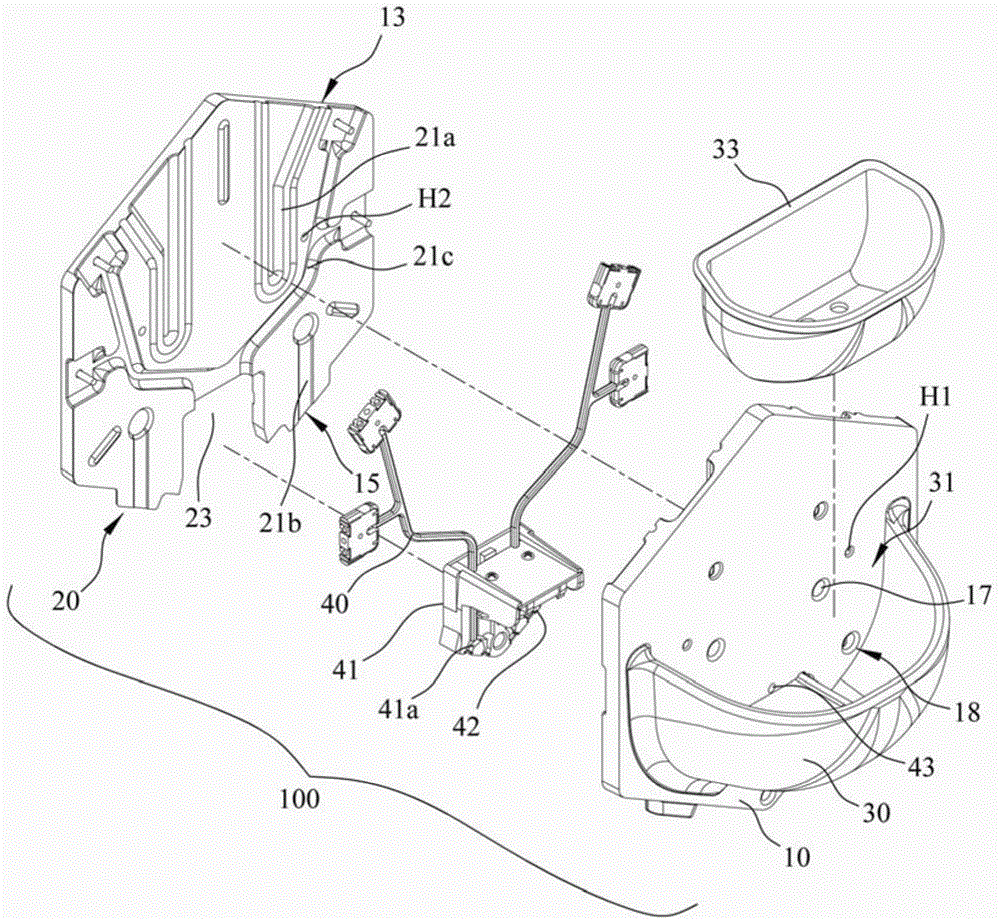

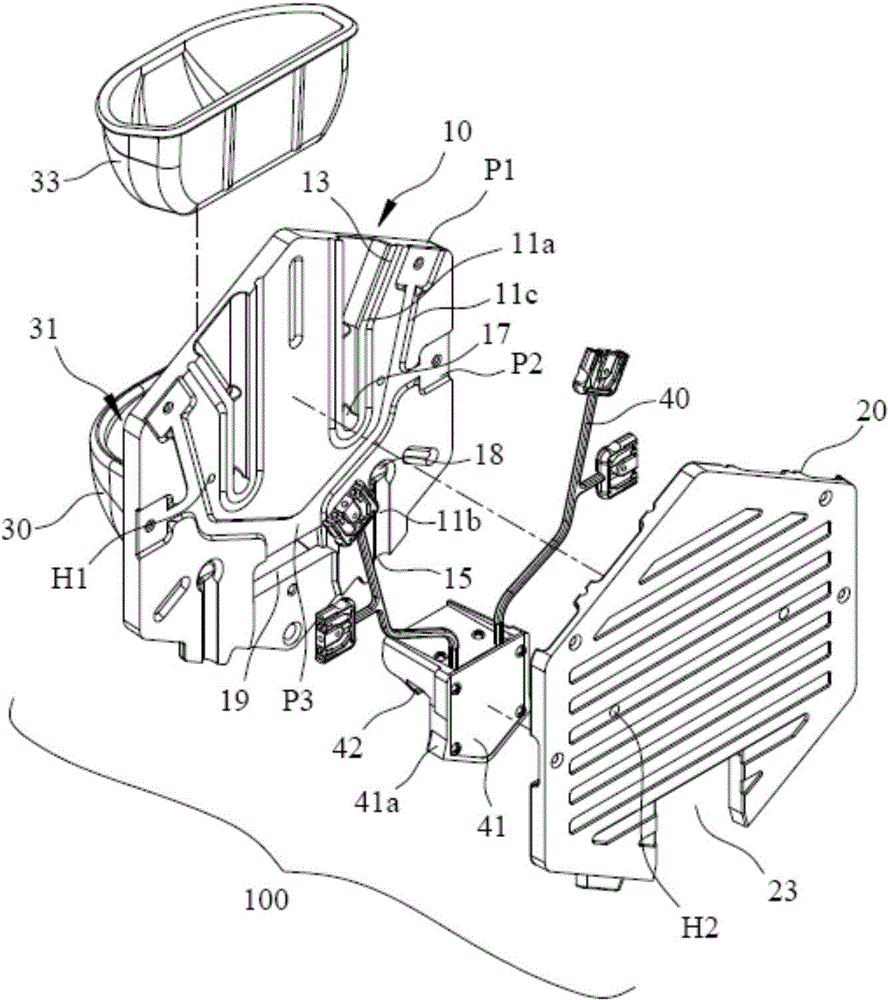

[0056] The implementation of the present invention will be described in more detail below with reference to the drawings and reference numerals, so that those skilled in the art can implement it after studying this specification.

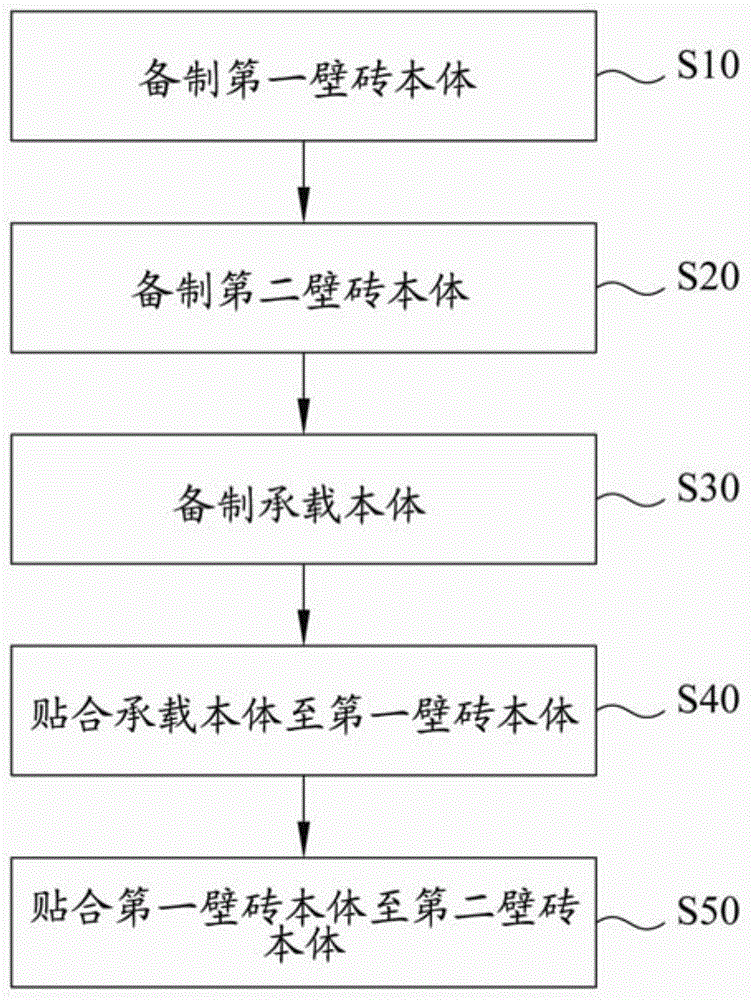

[0057] refer to figure 1 , a schematic diagram of the operation flow of the manufacturing method of the composite wall brick according to the embodiment of the present invention. Such as figure 1 As shown, the manufacturing method of the composite wall brick of the present invention includes the following steps: preparing the first wall brick body S10, preparing the second wall brick body S20, preparing the bearing body S30, and attaching the bearing body to the first wall brick body. The wall brick body S40 and the bonding of the first wall brick body to the second wall brick body S50 are used to make composite wall bricks with hidden internal water flow pipes and / or electrical pipes.

[0058] In order to clearly illustrate the technical characte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com