Inserting row for industrial furnaces

A technology for industrial furnaces and sockets, applied in furnaces, heat treatment furnaces, manufacturing tools, etc., can solve the problems that conventional sockets cannot meet, and achieve the effects of simple structure, convenient operation, light and flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiments are described in detail in conjunction with the accompanying drawings,

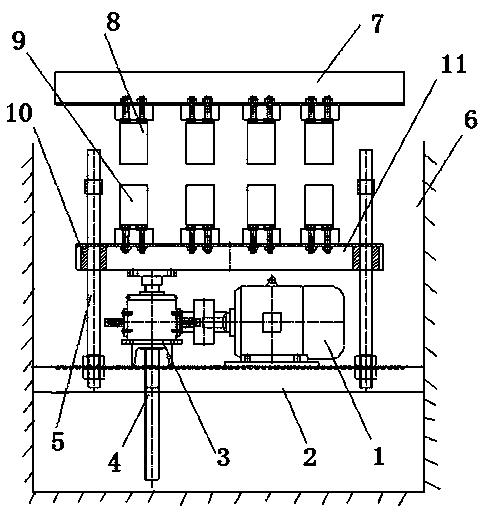

[0009] An insertion row used on an industrial furnace, which includes a fixed insertion row, a fixed insertion row 8 is provided at the bottom of the trolley 7, a pit 6 is preset at the center of the track in the furnace body, and a fixed bottom plate is arranged in the pit 2. One side of the fixed bottom plate is provided with a rotating motor 1, the output shaft of the motor drives the screw lifter 3, the upper part of the ejection shaft 4 of the screw lifter is fixedly connected with the movable frame 11, and the movable rack 9 is arranged above the movable frame, and the movable frame Both ends of the guide sleeve 10 are provided, the guide sleeve is set on the guide rod 5, and the guide rod is fixed on the fixed base plate;

[0010] The present invention can also increase the trolley positioning device to facilitate better positioning of the trolley. The trolley positioning device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com