Dry-process new type double-layer positive-negative once coating machine

A coating machine, a new type of technology, applied in textile processing machine accessories, textile and papermaking, liquid/gas/vapor textile processing, etc., can solve the problems of low efficiency, not easy to clean, easy to be dirty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

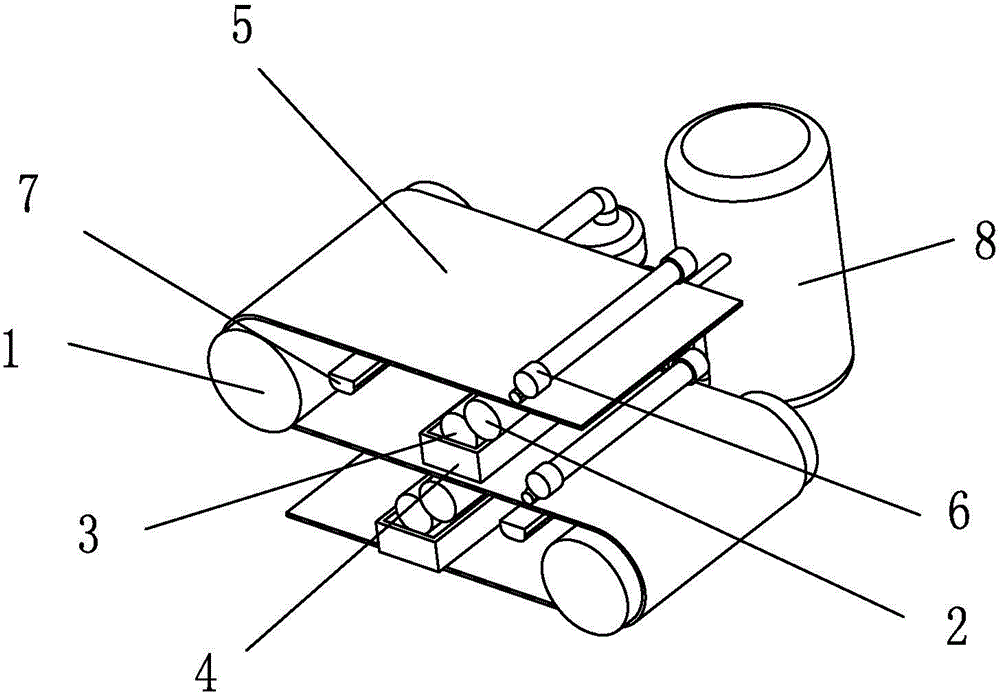

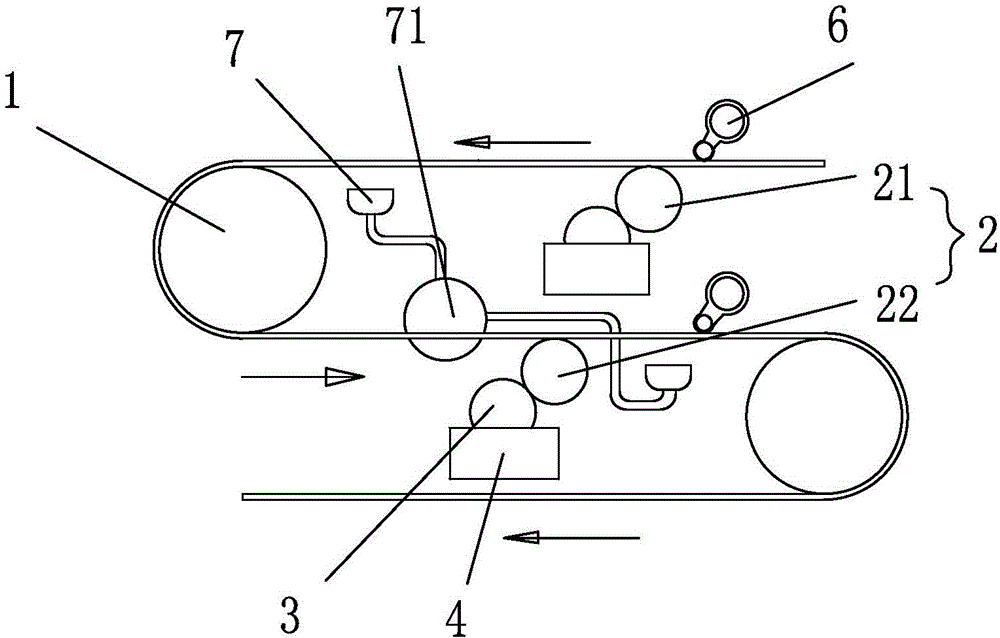

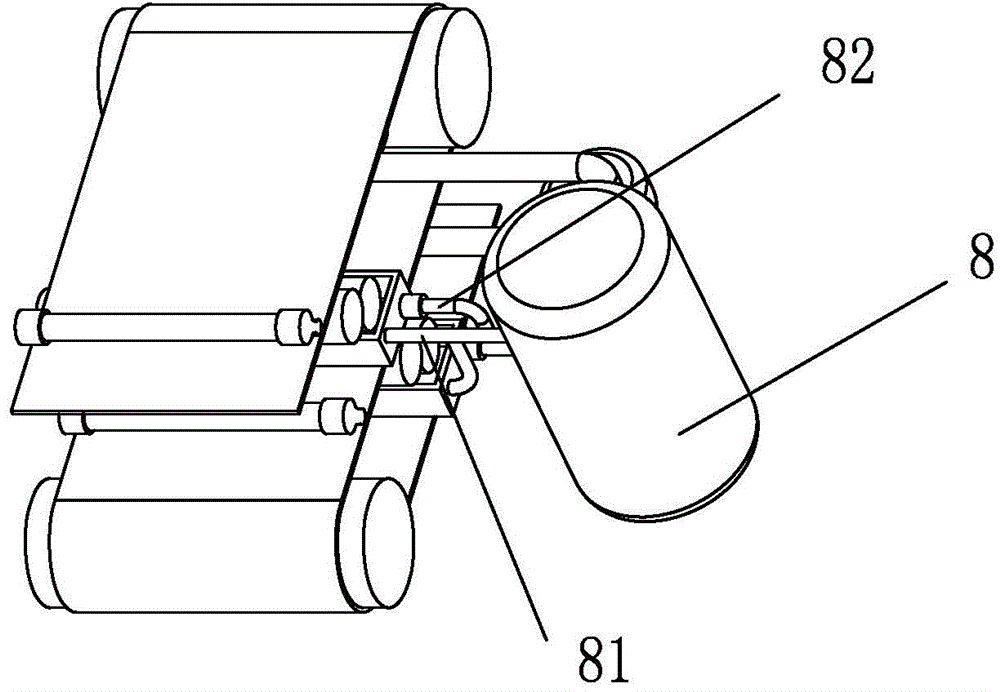

[0022] Such as Figure 1 to Figure 6 As shown, the dry-process new double-layer positive and negative one-time coating machine, the coating machine includes a transmission roller 1, the cloth 5 is transmitted on the transmission roller, and the coating machine is provided with a brushing roller 2 in contact with the surface of the cloth. The fabric is conveyed on two conveying rollers in an S shape, and the conveying diagram is as follows figure 1 and figure 2 As shown, there are two conveying rollers, and the cloth enters from the upper right side in the figure, and outputs from the lower left side after passing through the S-shaped route. The brushing roller includes the upper brushing roller 21 and the lower brushing roller Wheel 22, the upper brushing roller and the lower brushing roller are located on different height layers, wherein the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com