Ti(c,n)-based cermet reinforced and toughened by strip-shaped ternary boride and preparation method thereof

A ternary boride, strengthening and toughening technology, applied in the field of metal matrix composite materials, to achieve the effect of low raw material cost, improved service life and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

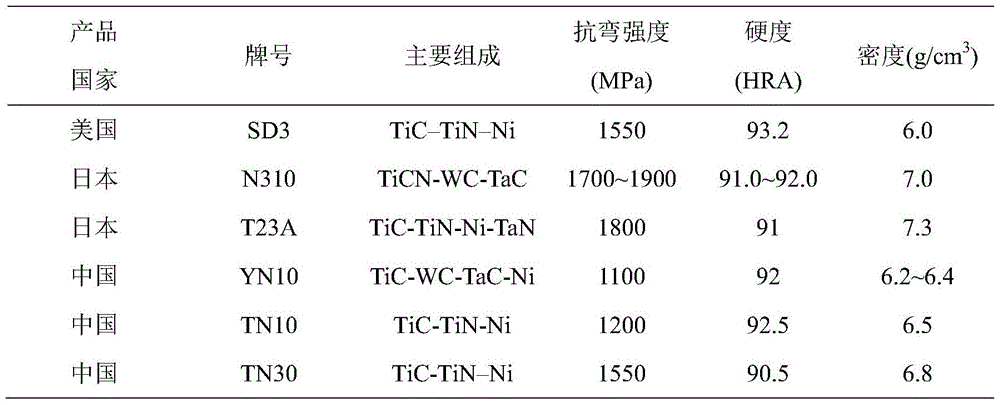

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] When preparing the mixture, Ti, C, and N are mainly introduced from titanium carbonitride solid solution; Ni and Mo are respectively introduced from nickel powder and molybdenum powder; W is introduced from tungsten carbide powder; Fe and B are introduced from ferroboron powder, of which 1 # and 2 # 0.5 part of C in the composition is introduced by graphite powder, 3 # and 4 # 1.0 part of C in the composition is introduced by graphite powder;

[0030] The mixing process is carried out in a planetary ball mill, the speed of the ball mill is 200rpm, and the time is 30h;

[0031] The addition amount of molding agent polyvinyl alcohol aqueous solution is 3wt%, and the pressure used for compression molding is 200MPa;

[0032] The degreasing process is carried out under the condition that the degree of vacuum is higher than 10Pa, and the heating rate between 200 and 400°C is 0.3°C / min;

[0033] The vacuum degree of vacuum sintering is higher than 1.0×10 -2 Pa. Vacuum si...

Embodiment 2

[0038] When preparing the mixture, Ti, C, and N are mainly introduced from titanium carbonitride solid solution; Ni and Mo are respectively introduced from nickel powder and molybdenum powder; W is introduced from tungsten carbide powder; Fe and B are introduced from ferroboron powder, of which 1 # and 2 # 0.5 part of C in the composition is introduced by graphite powder, 3 # and 4 # 1.0 part of C in the composition is introduced by graphite powder;

[0039] The mixing process is carried out in a planetary ball mill, the speed of the ball mill is 220rpm, and the time is 28h;

[0040] The addition amount of forming agent polyvinyl alcohol aqueous solution is 4wt%, and the pressure used for compression molding is 230MPa;

[0041] The degreasing process is carried out under the condition that the degree of vacuum is higher than 10Pa, and the heating rate between 200 and 400°C is 0.4°C / min;

[0042] The vacuum degree of vacuum sintering is higher than 1.0×10 -2 Pa. Vacuum si...

Embodiment 3

[0047] When preparing the mixture, Ti, C, and N are mainly introduced from titanium carbonitride solid solution; Ni and Mo are respectively introduced from nickel powder and molybdenum powder; W is introduced from tungsten carbide powder; Fe and B are introduced from ferroboron powder, of which 1 # and 2 # 0.5 part of C in the composition is introduced by graphite powder, 3 # and 4 # 1.0 part of C in the composition is introduced by graphite powder;

[0048] The mixing process is carried out in a planetary ball mill, the speed of the ball mill is 260rpm, and the time is 24h;

[0049] The addition amount of forming agent polyvinyl alcohol aqueous solution is 4wt%, and the pressure used for compression molding is 260MPa;

[0050] The degreasing process is carried out under the condition that the degree of vacuum is higher than 10Pa, and the heating rate between 200 and 400°C is 0.4°C / min;

[0051] The vacuum degree of vacuum sintering is higher than 1.0×10 -2 Pa. Vacuum si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com