Freeze-thaw-environment-resistant fiber composite recycled concrete column and preparation method thereof

A technology for recycling concrete and concrete columns, which is applied in the field of concrete to achieve the effects of high tensile strength, low water absorption, good dimensional stability and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

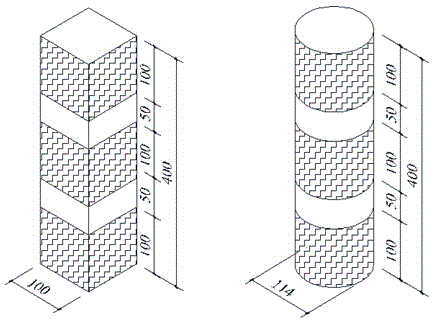

[0035] 1) In order, add fine aggregate, cement, primary coarse aggregate and recycled coarse aggregate, water in turn, and stir evenly in turn;

[0036] 2) Put the result of step 1) into steel pipe or carbon pipe, and vibrate evenly to form a recycled concrete column;

[0037] 3) Wrap the steel pipe recycled concrete column or carbon tube recycled concrete column obtained in step 2) with fibers;

[0038] In parts by weight, the proportioning relationship of each substance in step 1) is: 1 part of cement, 0.53 parts of water, 1.86 parts of sand, 1.72 parts of primary coarse aggregate, and 1.72 parts of recycled coarse aggregate. The amount of fiber in step 3) is 2 kg / m 3 Concrete column; the fine aggregate is natural river sand, the recycled coarse aggregate is waste concrete, and the original coarse aggregate is natural pebbles; the fiber is CFRP.

Embodiment 2

[0040] 1) In order, add fine aggregate, cement, primary coarse aggregate and recycled coarse aggregate, water in turn, and stir evenly in turn;

[0041] 2) Put the result of step 1) into steel pipe or carbon pipe, and vibrate evenly to form a recycled concrete column;

[0042] 3) Wrap the steel pipe recycled concrete column or carbon tube recycled concrete column obtained in step 2) with fibers;

[0043] In parts by weight, the proportioning relationship of each substance in step 1) is: 1 part of cement, 0.53 parts of water, 1.86 parts of sand, 1.72 parts of primary coarse aggregate, and 1.72 parts of recycled coarse aggregate. The amount of fiber in step 3) is 4 kg / m 3 Concrete column; the fine aggregate is natural river sand, the recycled coarse aggregate is waste concrete, and the original coarse aggregate is natural pebbles; the fiber is GFRP.

Embodiment 3

[0045] 1) In order, add fine aggregate, cement, primary coarse aggregate and recycled coarse aggregate, water in turn, and stir evenly in turn;

[0046] 2) Put the result of step 1) into steel pipe or carbon pipe, and vibrate evenly to form a recycled concrete column;

[0047] 3) Wrap the steel pipe recycled concrete column or carbon tube recycled concrete column obtained in step 2) with fibers;

[0048] In parts by weight, the proportioning relationship of each substance in step 1) is: 1 part of cement, 0.53 parts of water, 1.86 parts of sand, 1.72 parts of primary coarse aggregate, and 1.72 parts of recycled coarse aggregate. The amount of fiber in step 3) is 8 kg / m 3 Concrete column; the fine aggregate is natural river sand, the recycled coarse aggregate is waste concrete, and the original coarse aggregate is natural pebbles; the fiber is BFRP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com