Micro milling control system based on rotating laser beam mechanism

A control system and a technology of rotating beams, applied in the fields of laser milling and design laser processing, can solve the problems of surface quality damage of surface recast layer, excessive surface roughness of milling surface, restricting research work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The following exemplary embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

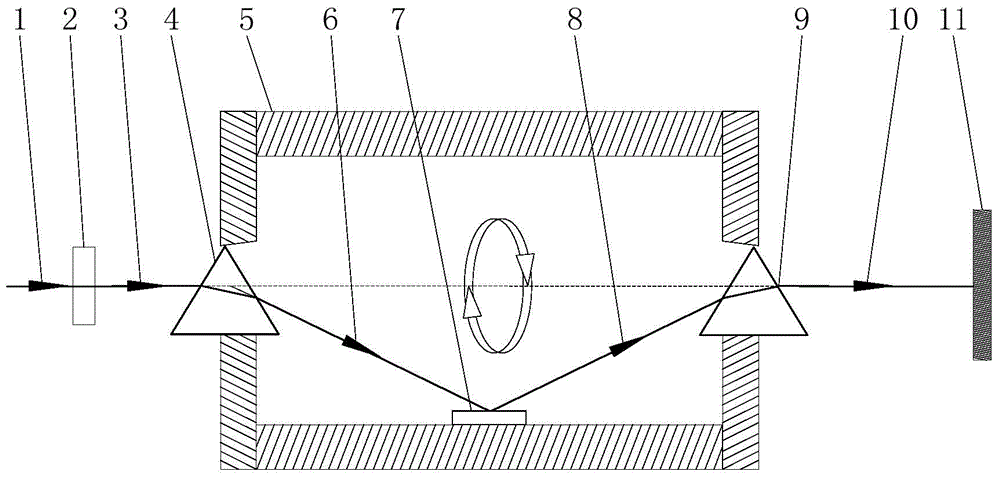

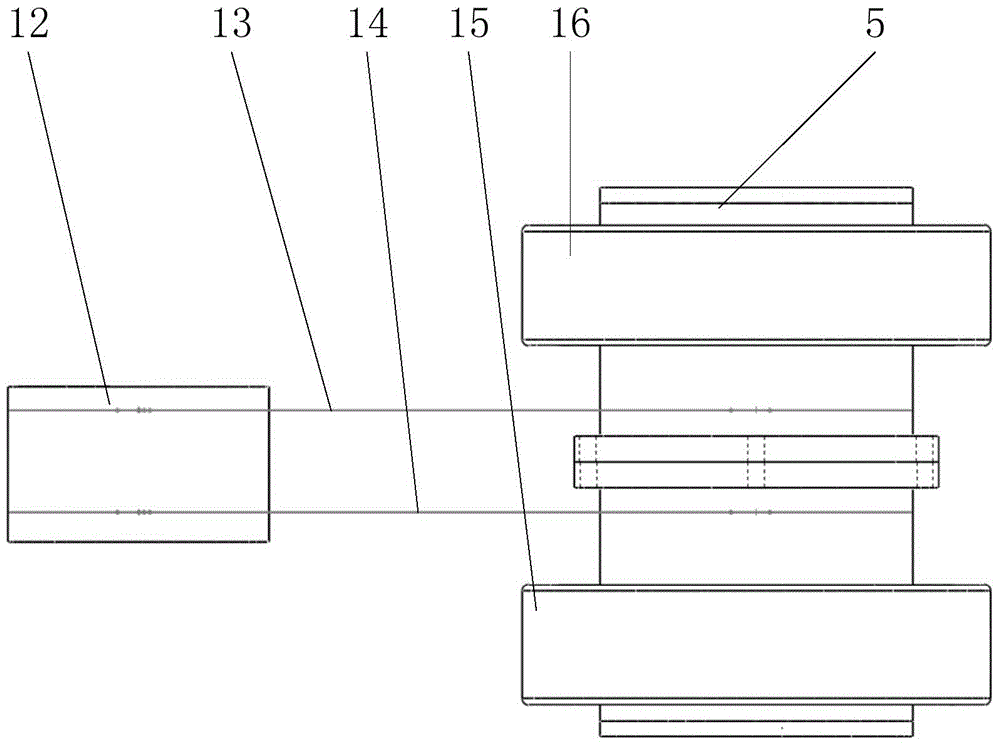

[0018] figure 1 Schematic diagram of how the optical path works for a rotating beam. It can be seen from the figure that the optical system is mainly composed of a focusing lens 2, two mirrors 4 and 9 with a deflection angle of 60°, and a plane mirror 7.

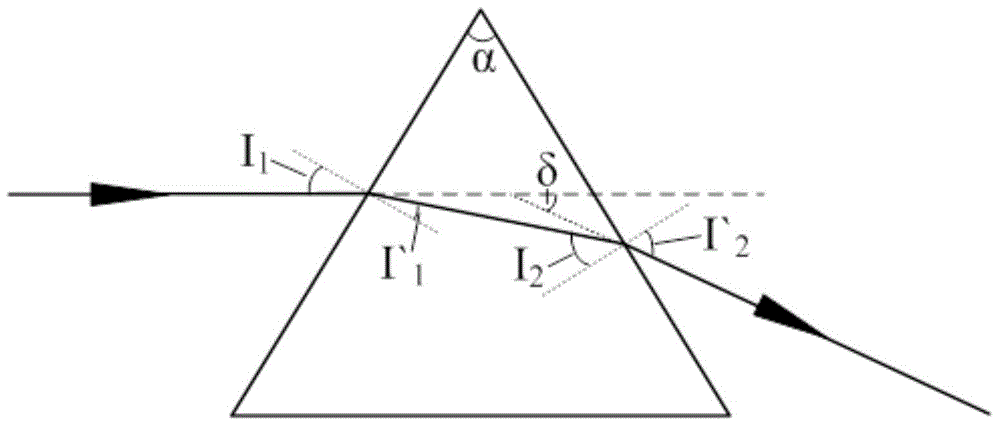

[0019] Select two triangular mirrors whose deflection angle is α=60°. The Mitsubishi mirror is ultraviolet optical quartz glass (JGS1), and its refractive index n=1.503 for ultraviolet light with a wavelength of 248 nanometers. figure 2 It is a schematic diagram of the refraction of light beams in a single triangular mirror. According to the refraction process of the light beam in the triangular mirror, sin' 1 =n s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com