Preparing method for finned inner cooling structure cooling pipe based on gel electrochemical machining

A technology of electrochemical machining and cooling structure, applied in electrochemical machining equipment, metal machining equipment, machining working medium and other directions, can solve the problems of complex structure and process, inability to carry out rib machining, poor cooling effect, etc., to control the machining reaction, Ease of control, the effect of reducing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Before electrochemical machining is performed, the processed parts need to be pretreated to ensure that the processed parts are suitable for the processing technology and prevent the generation of defective products. The main purpose is to remove the organic impurities contained in the inner wall of the tube, and to detect whether there is a defect in the inner wall of the tube. For inert metals (ranked after H hydrogen) should be activated.

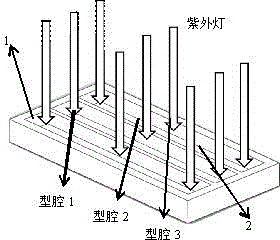

[0028] The electrolyte solution carrier of the present invention is a gel, and the method for preparing a solid-shaped gel with good conductivity is as follows: figure 1 As shown, dimethyl acetoacetamide DMAA (40% by mass), clay Clay (7%), photoinitiator DEAP (3%) and 4% sodium nitrate solution (50%) are used. A clear and transparent gel solution is obtained. The obtained solution is placed in the mold cavity 1, the entire device is placed under an ultraviolet lamp, and the polymerization reaction is carried out for 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com