Shearing clearance adjusting device for metal pull-down shearing pliers

A gap adjustment device and technology of gap adjustment, which are applied in shearing devices, accessories of shearing machines, metal processing equipment, etc., can solve the problems of blocking movable blades and fixed blades, unable to cut, and deformation of movable and fixed bodies. , to achieve the effect of changing the gap, accurate and firm positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

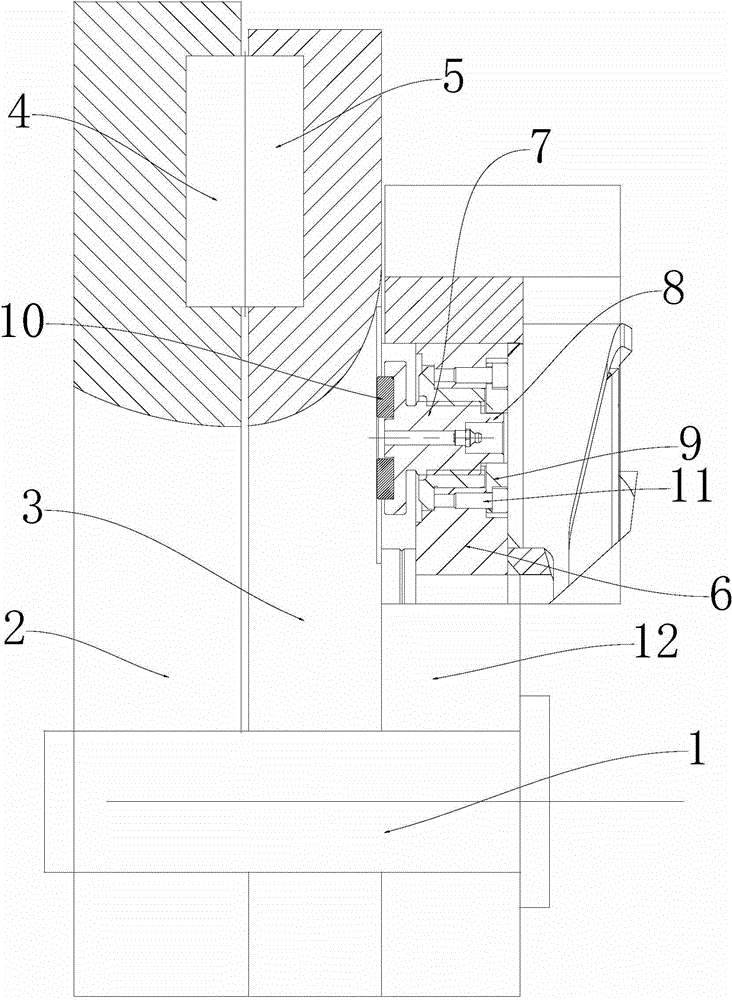

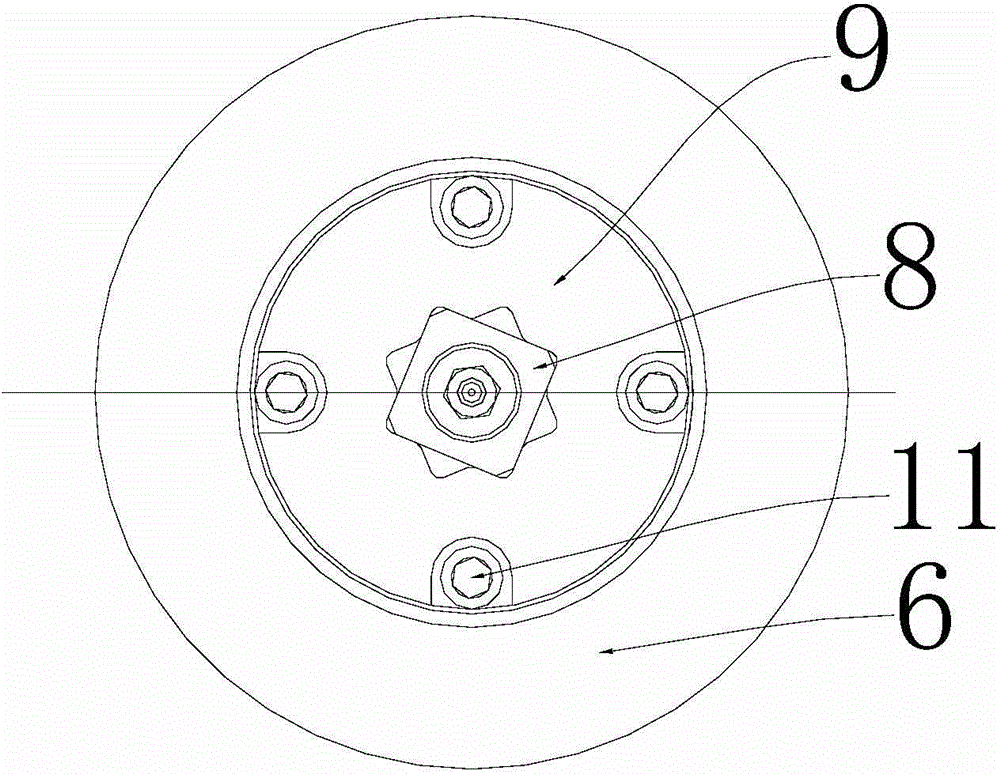

[0014] Such as figure 1 , figure 2 As shown, the pliers cutting gap adjustment device for breaking and shearing metal described in this embodiment includes a movable body 3, a fixed body 2, and a moving body transfer shaft 1. The movable body 3 is equipped with a movable blade 5, and the fixed body 2 The upper assembly is equipped with a fixed blade 4, and the movable body 3 and the fixed body 2 are both sleeved on the movable body transfer shaft 1; a support body 12 is arranged on the solid outside the movable body 3, and the support body 12 is axially fixed relative to the movable body 3 , the movable body 3 can rotate relative to the support body 12; a spiral gap adjustment seat 6 is arranged above the support body 12, and a spiral gap adjustment column 7 is arranged inside the spiral gap adjustment seat 6, and the spiral gap adjustment column 7 is connected to the The screw-type gap adjustment seats 6 are connected through threaded rotation, and the end of the screw-type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com