Automatic punching machine tool for disk slices

An automatic punching and machine tool technology, applied in thin material handling, feeding devices, manufacturing tools, etc., can solve problems affecting factory production efficiency, low processing efficiency, and high labor costs, saving manpower, improving efficiency, and automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

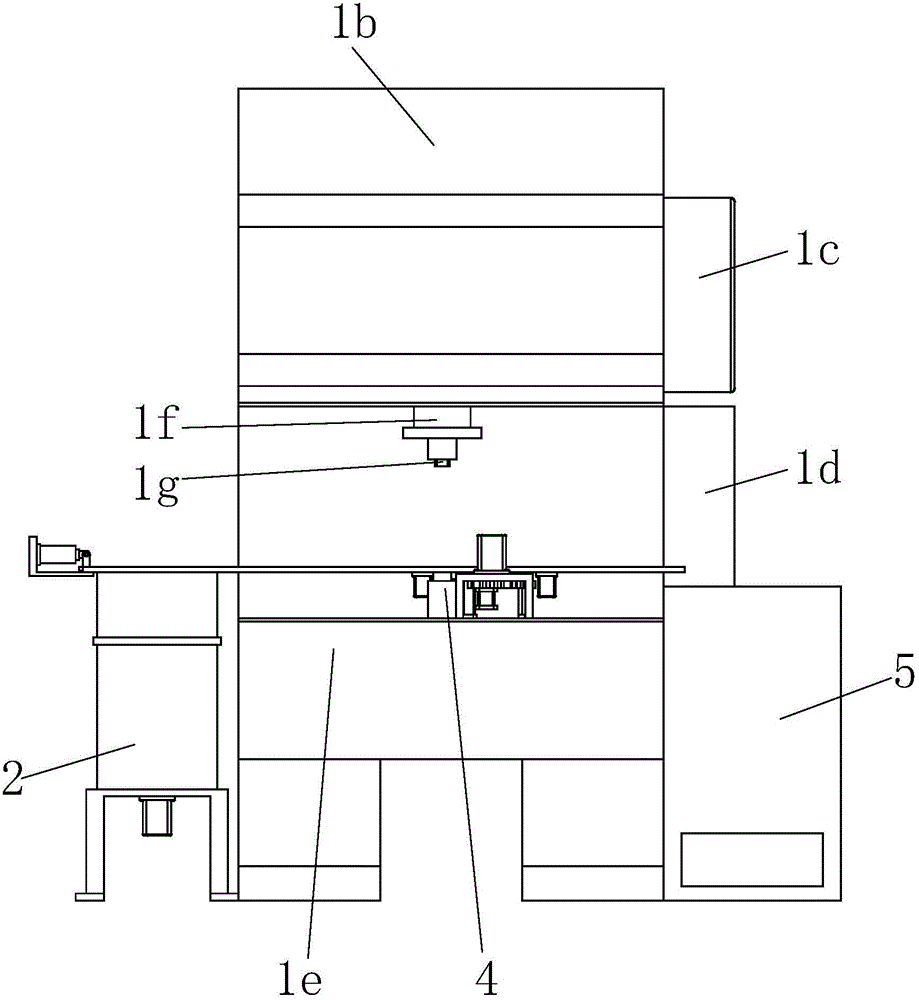

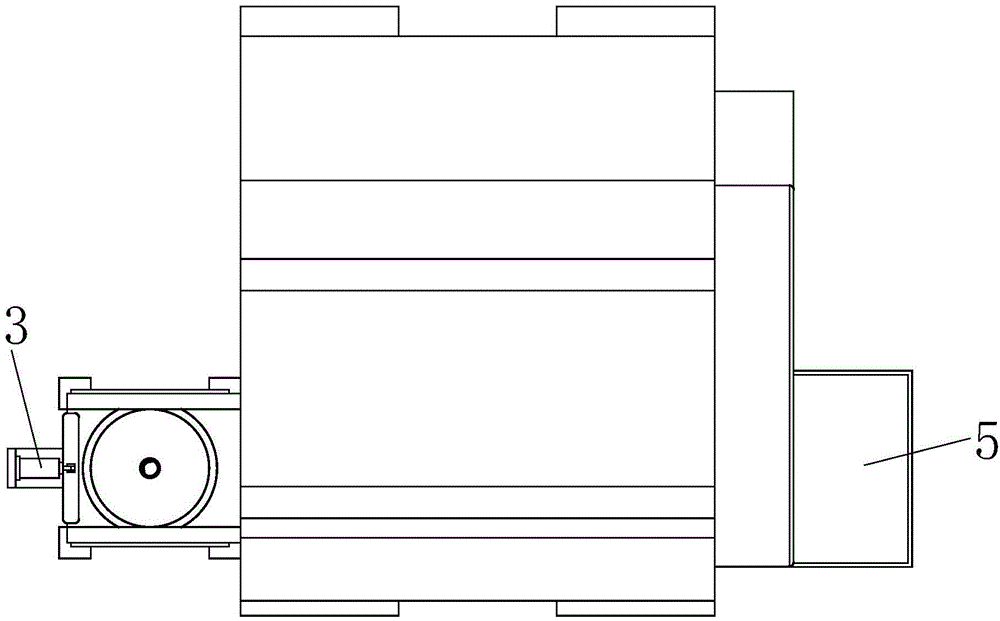

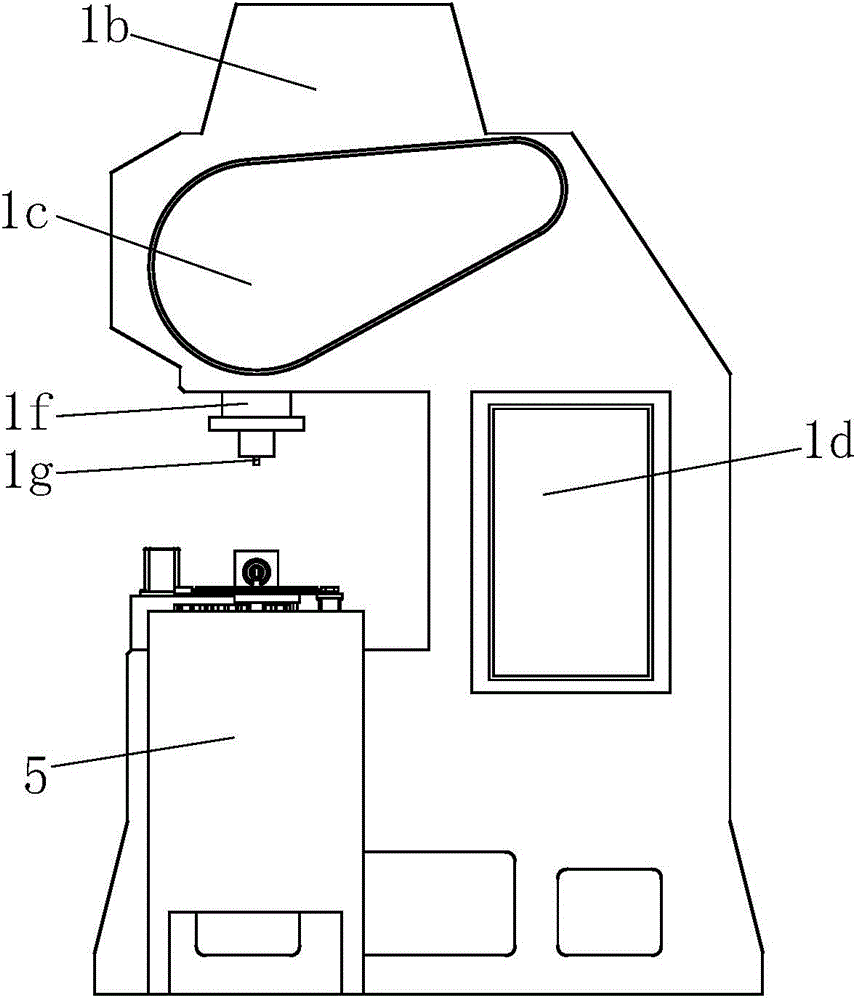

[0027] Such as Figure 1 to Figure 14As shown, a disc-like sheet automatic punching machine tool includes a machine tool body 1, an automatic feeding device 2, a single-piece processing and conveying device 3, a rotary punching device 4 and a receiving bin 5, and the machine tool body 1 Including machine base 1a, main drive box 1b, transmission device 1c, main control box 1d, workbench 1e, lifting shaft 1f and main cutter 1g, said main drive box 1b is arranged on the top of machine base 1a, said transmission device 1c Fixed on the right side of the main drive box 1b, the main control box 1d is installed in the middle of the right side of the machine base 1a, the workbench 1e is arranged on the front side of the machine base 1a, and the lifting shaft 1f is located at the main drive box 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com