A Side Excitation Ultrasonic Elliptical Vibration Milling Tool Holder

A technology of elliptical vibration and ultrasonic vibration, applied in milling cutters, fluids using vibration, milling machine equipment, etc., can solve the problem that the excellent characteristics of ultrasonic vibration processing are not fully exerted, the processing ability of difficult-to-machine metal materials is limited, and the form of tool vibration is single, etc. problems, to achieve the effects of excellent processing quality, improved processing quality and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

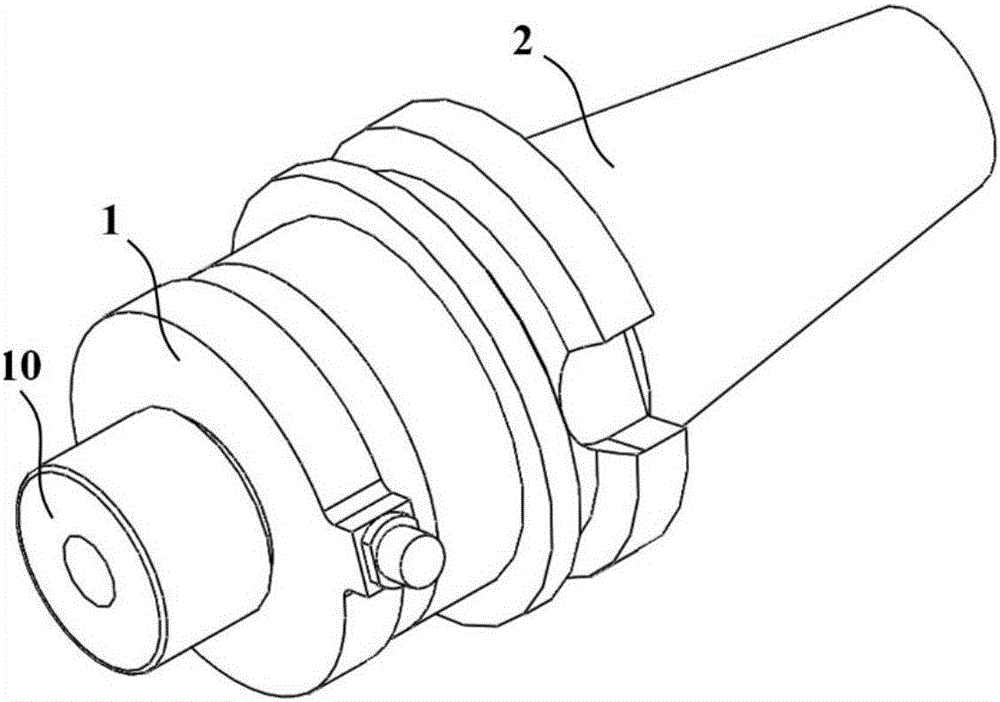

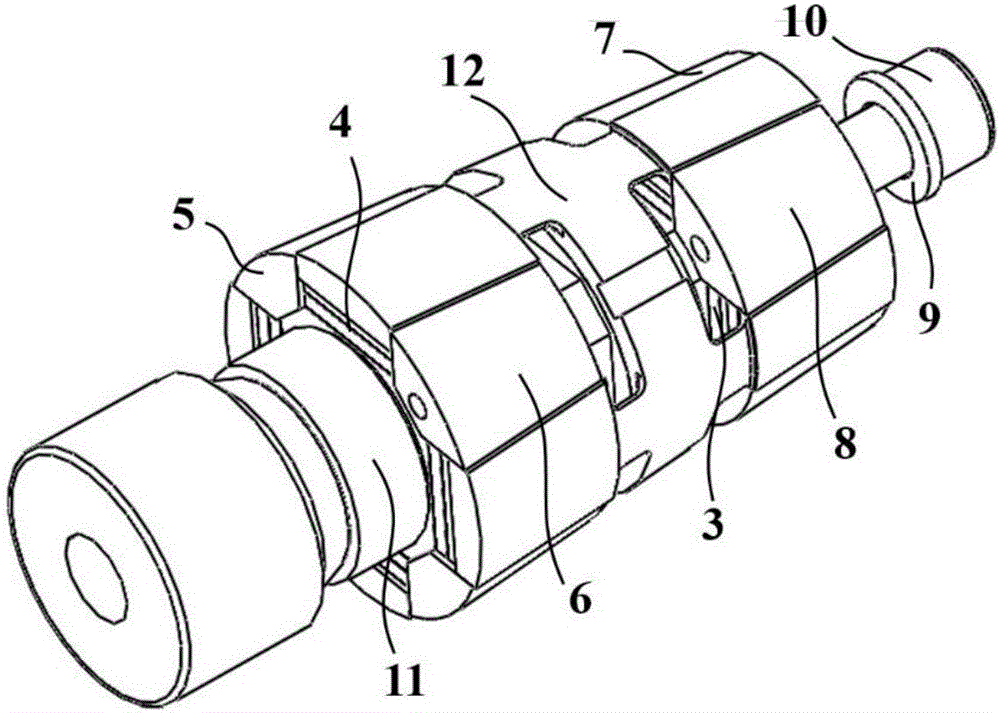

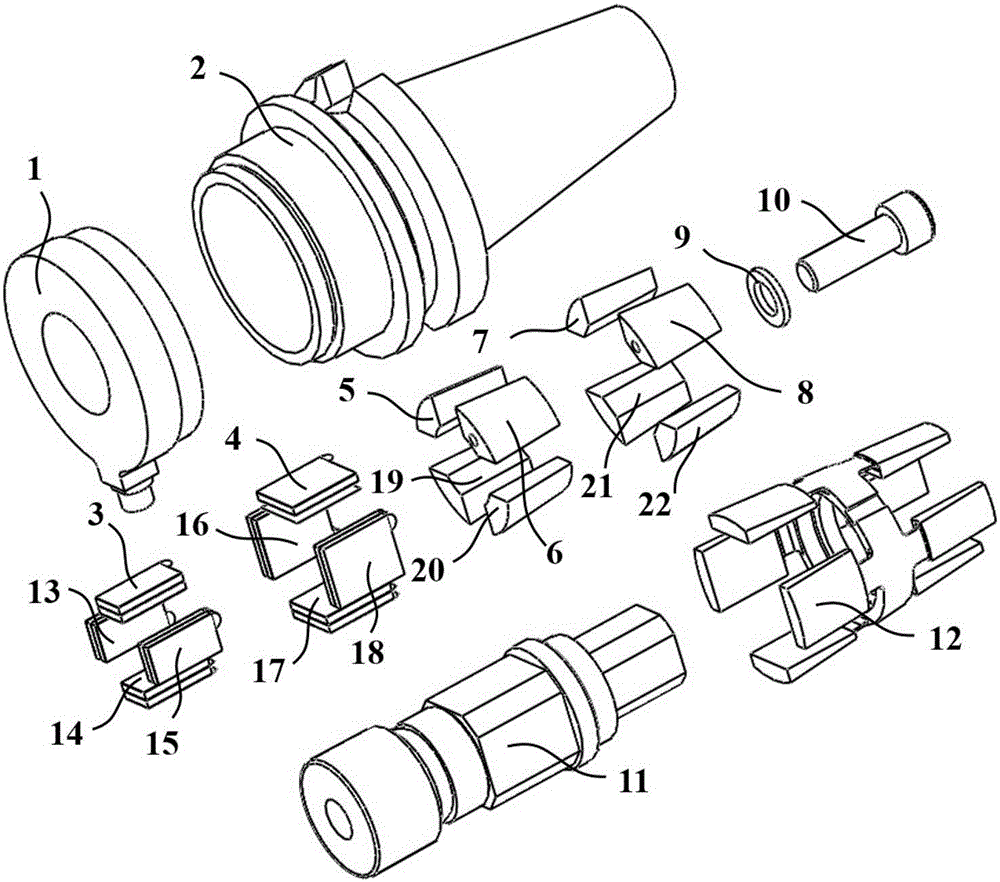

[0049] See figure 1 —— image 3 , the present invention is a side-excited ultrasonic elliptical vibration milling tool holder, the components include a conductive slip ring 1, a BT50 tool holder 2, four sets of Type I ceramic stacks (Type I ceramic stack A 3, Type I ceramic stack B13, Type I ceramic pile C14, Type I ceramic pile D15), four groups of Type II ceramic piles (Type II ceramic pile A 4, Type II ceramic pile B 16, Type II ceramic pile C 17, Type II ceramic pile D 18), three One Ⅰ-1 type nylon protection block (Ⅰ-1 type nylon protection block A 5, Ⅰ-1 type nylon protection block B 19, Ⅰ-1 type nylon protection block C 20), one Ⅰ-2 type nylon protection block 6, Three Ⅱ-1 type nylon protection blocks (Ⅱ-1 type nylon protection block A 7, Ⅱ-1 type nylon protection block B 21, Ⅱ-1 type nylon protection block C 22), one Ⅱ-2 type nylon protectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com