Efficient and sustainable production method for greenhouse and fruit tree potting media

A continuous production and greenhouse technology, applied in the field of high-efficiency and sustainable production methods in greenhouses and the field of fruit tree potting substrates, can solve the problem of low utilization rate of greenhouses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

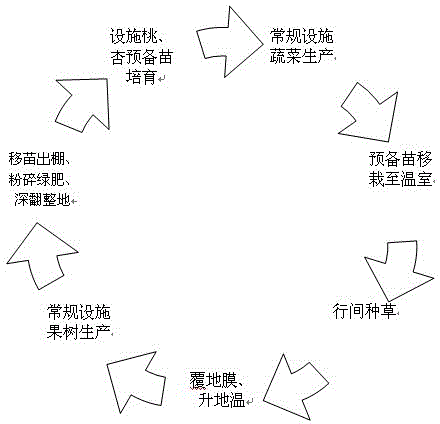

[0040] A greenhouse efficient and sustainable production method, comprising the following steps:

[0041] (1) Cultivation of prepared peach seedlings in facilities. This step is the third step to cultivate the material.

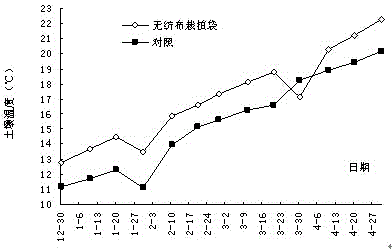

[0042] In mid-to-late March, choose high-quality seedlings with a low-cooling variety Shuguang. The ratio of pollination varieties to cultivated varieties is 1:3. Seedlings require full buds, thick branches, and complete and well-developed root systems. A non-woven bag with a diameter of 30 cm and a depth of 30 cm (volume about 20 L) was used as a cultivation container. Using slag, decomposed high-quality farmyard manure and garden soil as raw materials, the cultivation substrate is prepared by mixing slag: decomposed high-quality organic fertilizer: garden soil = 2:1:3.

[0043] The cultivation medium is prepared according to the above-mentioned ratio for later use, and then the prepared cultivation medium is put into a cultivation container, and the water...

Embodiment 2

[0058] A greenhouse efficient and sustainable production method, comprising the following steps:

[0059] (1) Cultivation of prepared apricot seedlings in facilities. This step is the third step to cultivate the material.

[0060] In the middle and late March, choose Kate, a variety that requires less cooling. The ratio of pollination varieties to cultivated varieties is 1:3. High-quality seedlings. Seedlings require full buds, thick branches, and complete and well-developed root systems. A non-woven bag with a diameter of 30 cm and a depth of 30 cm (volume about 20 L) was used as a cultivation container. Using slag, decomposed high-quality farmyard manure and garden soil as raw materials, the cultivation substrate is prepared by mixing slag: decomposed high-quality organic fertilizer: garden soil = 2:1:3.

[0061] The cultivation medium is prepared according to the above-mentioned ratio for later use, and then the prepared cultivation medium is put into a cultivation contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com