Adhesive-free graphene/silicon electrode for lithium ion battery and preparation method thereof

A lithium-ion battery, binder-free technology, applied in the direction of battery electrodes, non-aqueous electrolyte storage battery electrodes, electrode manufacturing, etc., can solve the problems of unsuitable for large-scale industrial production, lack of electrode conductivity, and difficulty in industrial production, etc., to achieve Good dispersion effect, improved capacity and cycle performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

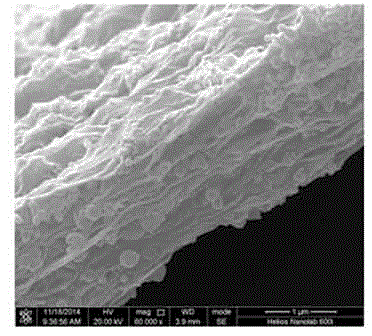

Image

Examples

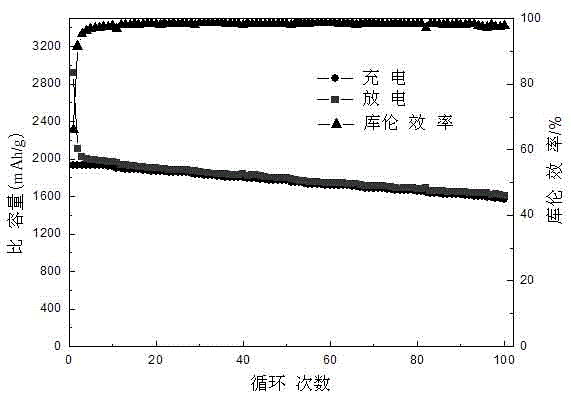

Embodiment 1

[0038] The present embodiment provides a kind of preparation method of binder-free graphene / silicon electrode for lithium ion battery, and concrete steps are as follows:

[0039] 1. Preparation of pre-oxidized graphite:

[0040] Add 39mL of concentrated sulfuric acid (98%) into a three-necked flask, then weigh 2.5g of potassium persulfate and 2.5g of phosphorus pentoxide and add them to the three-necked flask successively, mix well; then add 5g of natural flake graphite powder (325 mesh), Then place it in a constant temperature water bath and react for 6 hours under stirring at 80°C; slowly pour the reactant into a beaker filled with 700ml of deionized water for dilution, transfer the diluted liquid to a Buchner funnel for filtration, and wash until the filtrate The obtained filter cake was dried under vacuum at 100°C for 10 hours, and the obtained solid substance was pre-oxidized graphite.

[0041] Two, the preparation of graphite oxide solution:

[0042] Weigh 2.5g of pre-ox...

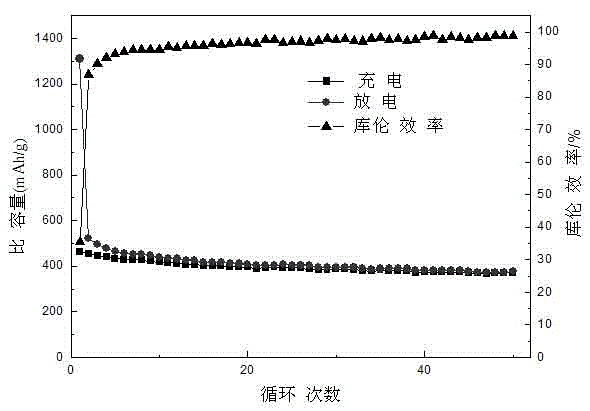

Embodiment 2

[0052] The present embodiment provides a kind of preparation method of binder-free graphene / silicon electrode for lithium ion battery, and concrete steps are as follows:

[0053] 1. Preparation of pre-oxidized graphite:

[0054] Mix 3g of natural flake graphite (100 mesh) with 2.5g of potassium persulfate and 2.5g of phosphorus pentoxide into a three-necked flask filled with 50mL of concentrated sulfuric acid (98%), mix well under magnetic stirring conditions, and then place at constant temperature In a water bath, react for 6 hours under stirring at 80°C; slowly pour the reactant into a beaker filled with 500ml deionized water for dilution, then filter and wash with a Buchner funnel until the filtrate becomes neutral; filter the cake in a vacuum Dry at 80°C for 20 hours, and the resulting solid substance is pre-oxidized graphite.

[0055] Two, the preparation of graphite oxide solution:

[0056] Take 2.5g of pre-oxidized graphite and 1.25g of sodium nitrate and add them to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

| Coulombic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com