Moderate-strength abnormally-shaped heat-resistant aluminum alloy overhead conductor

An overhead wire and aluminum alloy technology, applied in the field of power overhead wires, to achieve the effects of no electromagnetic induction loss, convenient and simple connection, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

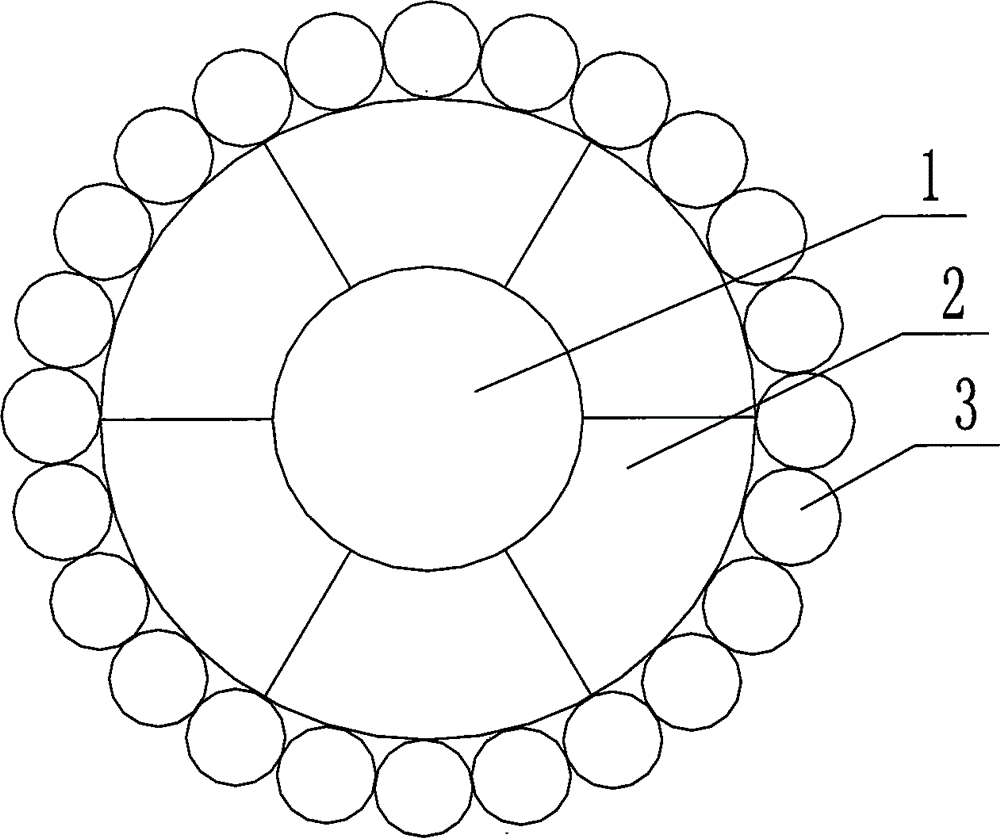

[0018] Embodiment 1: as figure 1 As shown, the heat-resistant circular aluminum alloy core wire 1 in the inner layer, the heat-resistant trapezoidal aluminum alloy monofilament 2 in the middle layer and the heat-resistant circular aluminum alloy monofilament 3 in the outer layer are twisted together. The heat-resistant circular aluminum alloy core wire 1 has a circular cross-section, the heat-resistant trapezoidal aluminum alloy monofilament 2 in the middle layer has a trapezoidal cross-section, and the heat-resistant circular aluminum alloy monofilament 3 in the outer layer has a circular cross-section. Two heat-resistant trapezoidal aluminum alloy monofilaments are concentrically twisted in one layer around the heat-resistant round aluminum alloy core wire 1, and the number of heat-resistant trapezoidal aluminum alloy monofilaments 2 per layer is six.

Embodiment 2

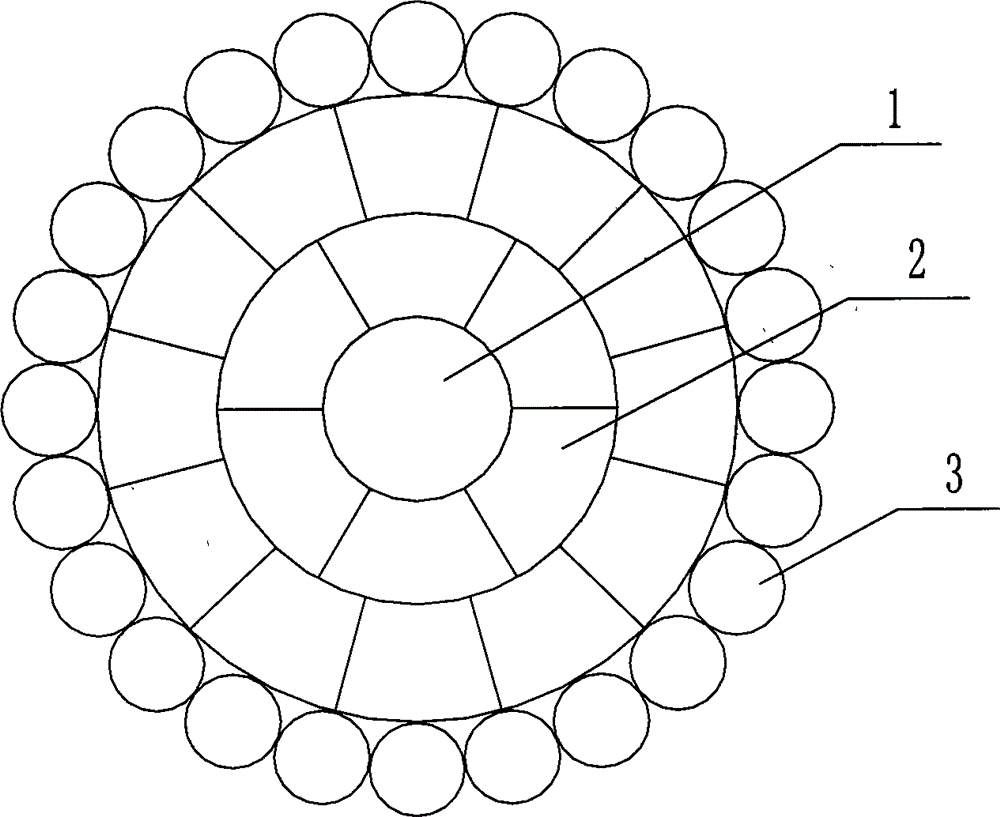

[0019] Embodiment 2: as figure 2 As shown, the heat-resistant circular aluminum alloy core wire 1 in the inner layer, the heat-resistant trapezoidal aluminum alloy monofilament 2 in the middle layer and the heat-resistant circular aluminum alloy monofilament 3 in the outer layer are twisted together. The heat-resistant circular aluminum alloy core wire 1 has a circular cross-section, the heat-resistant trapezoidal aluminum alloy monofilament 2 in the middle layer has a trapezoidal cross-section, and the heat-resistant circular aluminum alloy monofilament 3 in the outer layer has a circular cross-section. The heat-resistant trapezoidal aluminum alloy monofilament 2 is concentrically twisted in two layers from the inside to the outside around the heat-resistant circular aluminum alloy core wire 1. The number of heat-resistant trapezoidal aluminum alloy monofilament 2 in the first layer is 6 pieces, and the second layer The number of heat-resistant trapezoidal aluminum alloy mon...

Embodiment 3

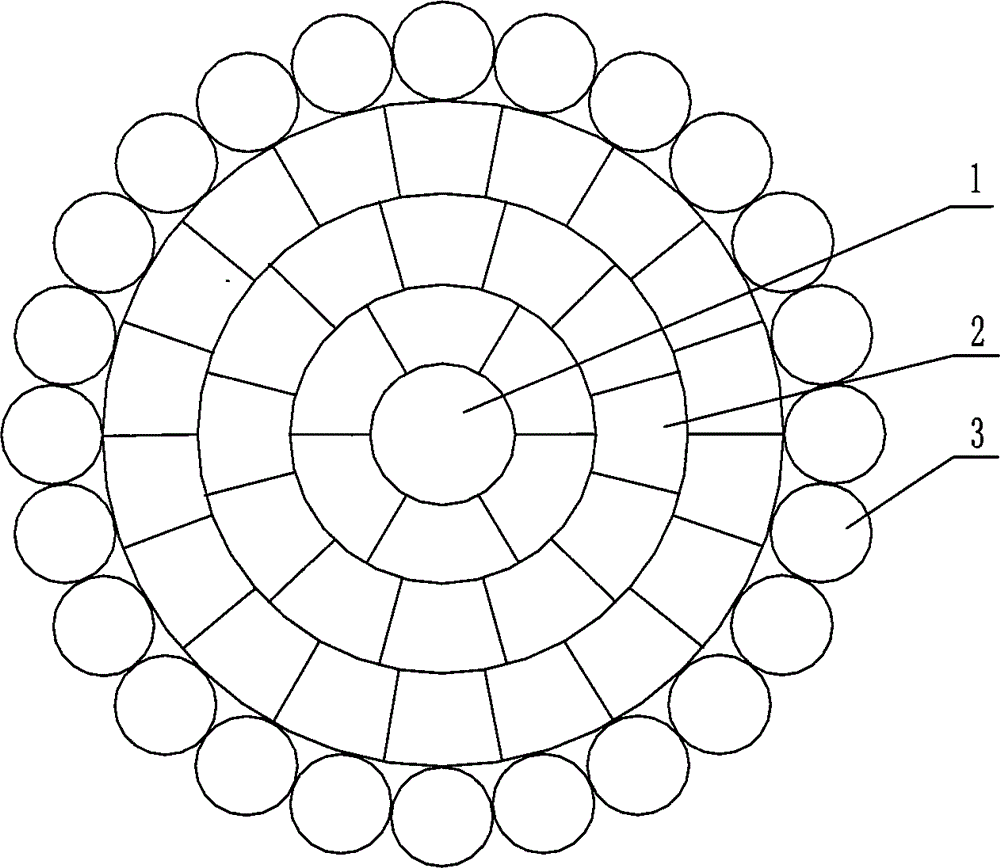

[0020] Embodiment 3: as image 3 As shown, the heat-resistant circular aluminum alloy core wire 1 in the inner layer, the heat-resistant trapezoidal aluminum alloy monofilament 2 in the middle layer and the heat-resistant circular aluminum alloy monofilament 3 in the outer layer are twisted together. The heat-resistant circular aluminum alloy core wire 1 has a circular cross-section, the heat-resistant trapezoidal aluminum alloy monofilament 2 in the middle layer has a trapezoidal cross-section, and the heat-resistant circular aluminum alloy monofilament 3 in the outer layer has a circular cross-section, and the heat-resistant trapezoidal aluminum alloy core wire has a circular cross-section. The alloy monofilament 2 is concentrically twisted in three layers from the inside to the outside around the heat-resistant circular aluminum alloy core wire 1. The number of heat-resistant trapezoidal aluminum alloy monofilaments 2 in the first layer is 6, and the second layer The number...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com