Visual triaxial test system

A triaxial test, positioning plate technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as inability to use, glass breakage, etc., and achieve the effects of easy assembly, low cost, and accurate test data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

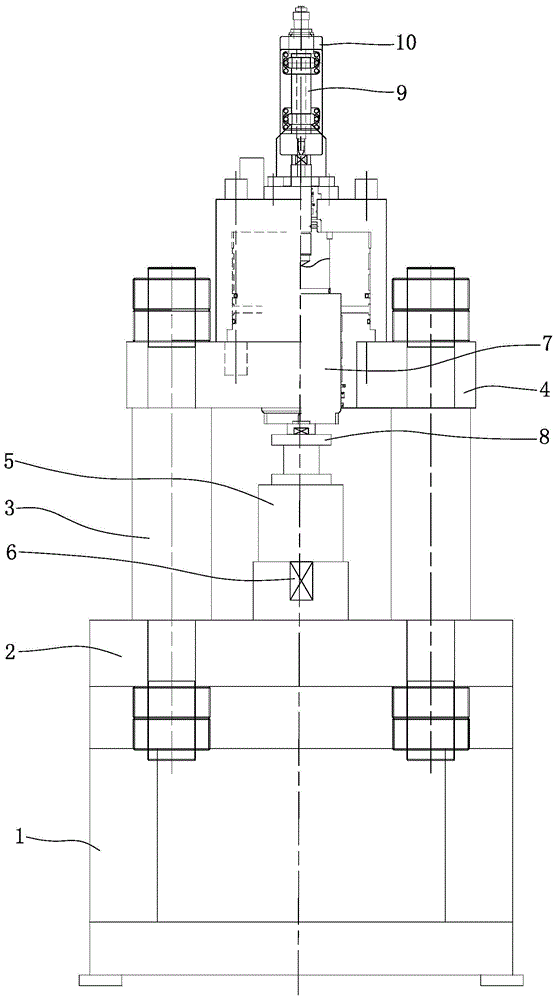

[0039] Such as figure 1 As shown, the fixed frame 1 is a frame structure, and the four corners of the bottom of the fixed frame 1 are equipped with anchor bolts. A lower positioning plate 2 is arranged on the top of the fixing frame 1, and the lower positioning plate 2 is preferably rectangular and located on a horizontal plane. Directly above the lower positioning plate 2 is provided with an upper positioning plate 4, and the upper positioning plate 4 is also preferably rectangular. The reaction force column 3 is connected, and the reaction force column 3 is perpendicular to the upper positioning plate 4, and the upper and lower ends of the reaction force column 3 are locked with the corresponding positioning plate by nuts.

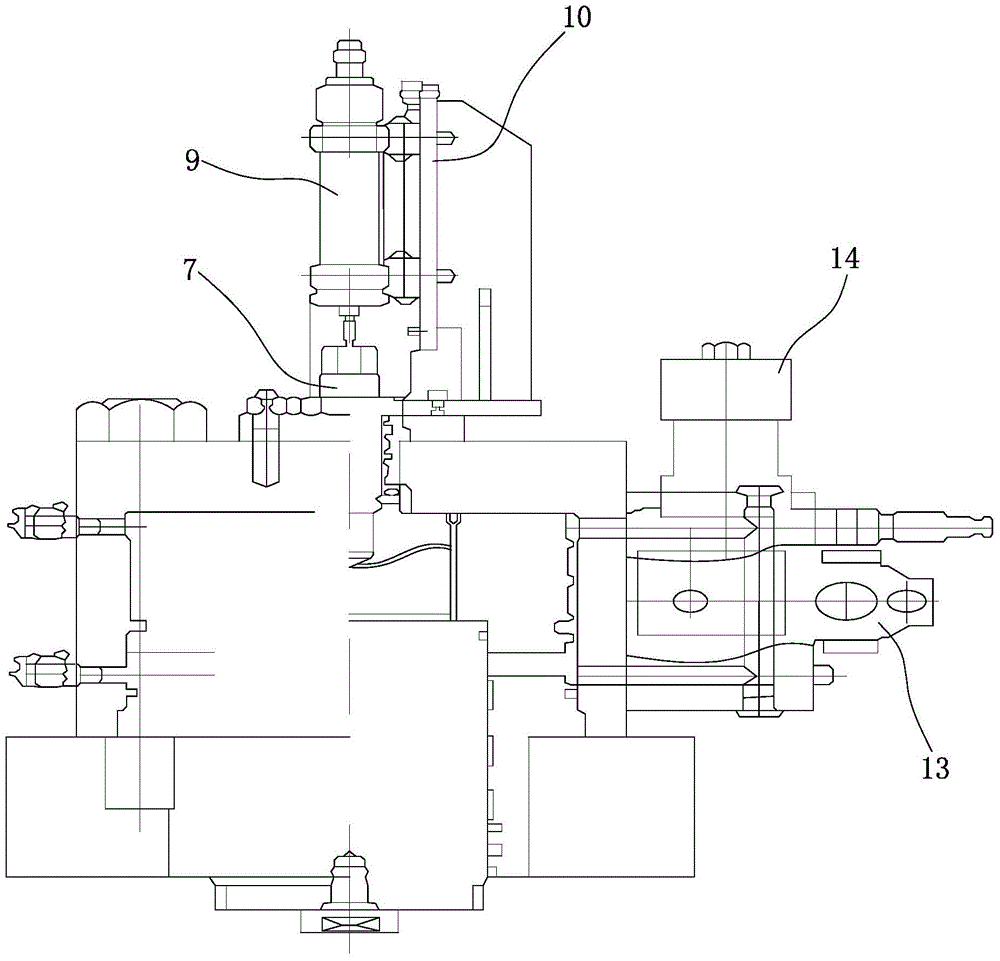

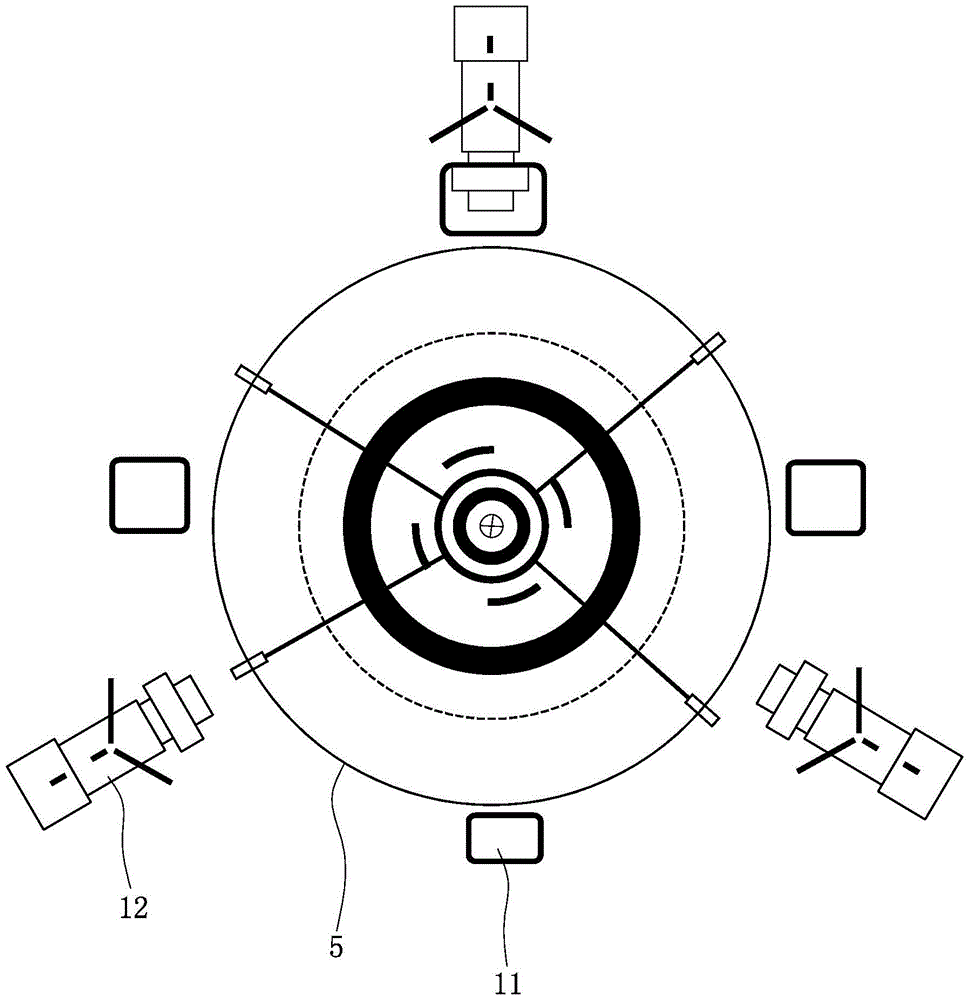

[0040] Such as figure 1 , figure 2 As shown, a pedestal is fixed at the center of the top surface of the lower positioning plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com