Flexible wearable paper-based strain sensor and preparation method thereof

A strain sensor and paper-based technology, applied in the field of sensors, can solve the problems of long preparation cycle and complicated preparation process, and achieve the effects of fast strain detection, simple preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing a flexible wearable paper-based strain sensor, the method steps are as follows:

[0031] (1) Cut the printing paper into a rectangular shape of the specified size to make an insulating layer;

[0032] (2) Use a pen containing graphite to blacken the surface of the printing paper cut in step (1) to form a continuous and uninterrupted graphite film to make a conductive layer;

[0033] (3) The two ends of the conductive layer obtained in step (2) along the length direction were connected to wires and fixed with conductive silver glue to obtain a flexible wearable paper-based strain sensor.

[0034] The material for making the insulating layer is not limited to the above-mentioned printing paper, and other materials can also be used, including: the paper base material for making the insulating layer is not limited to the printing paper, filter paper, test paper and other flexible papers with rough surfaces.

[0035] Pens containing graphite for makin...

Embodiment 1

[0038] (1) Cut the printing paper with a thickness of 100 microns into a rectangle with a length of 4 cm and a width of 0.5 cm;

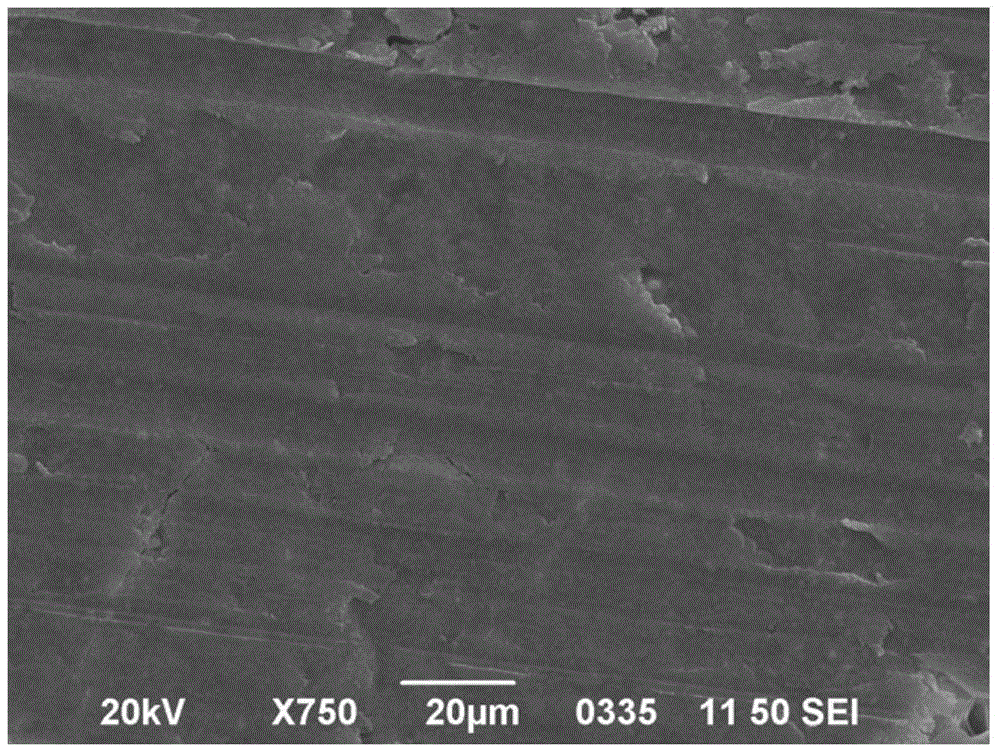

[0039] (2) Use a 2B pencil to blacken the surface of the printing paper cut in step (1) to form a continuous graphite film. The microstructure of the graphite film is as follows: image 3 shown;

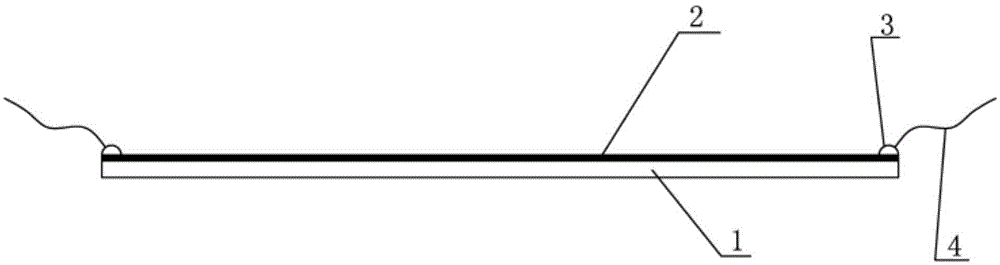

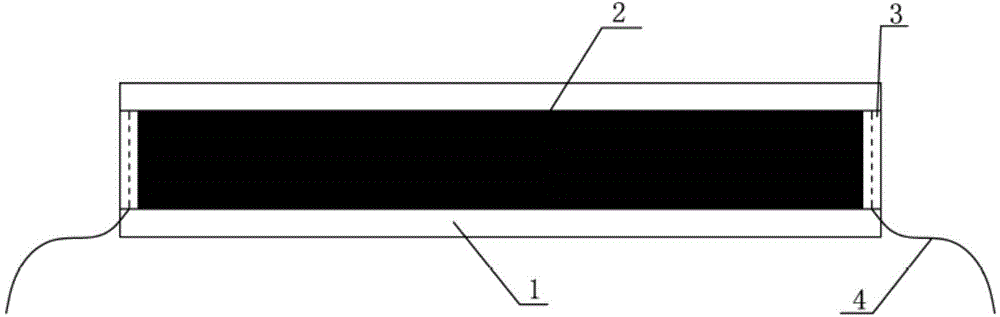

[0040](3) Lead wires from both ends of the printing paper obtained in step (2) along the length direction with silver glue to obtain a flexible wearable paper-based strain sensor. The structure diagram is as follows figure 1 shown;

[0041] (4) Fix the sensor obtained in step (3) with a length of 4 cm and a width of 0.5 cm on the finger with double-sided tape, and then it can be used for bending detection of the finger.

Embodiment 2

[0043] (1) Cut the filter paper with a thickness of 500 μm into a rectangle with a length of 2 cm and a width of 1 cm;

[0044] (2) Use a 2B pencil to blacken the surface of the printing paper cut in step (1) to form a continuous graphite film. The microstructure of the graphite film is as follows: image 3 shown;

[0045] (3) Lead wires from both ends of the printing paper obtained in step (2) along the length direction with silver glue to obtain a flexible wearable paper-based strain sensor. The structure diagram is as follows figure 1 shown;

[0046] (4) Fix the sensor obtained in step (3) with a length of 2 cm and a width of 1 cm in the corner of the book with double-sided tape, and then it can be used to detect the opening and closing angle of the book.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com