Built-in flue smoke amount distributing control system of economizer

A technology for controlling system and flue gas volume, which is applied to the field of flue gas volume diversion control system built into economizers, can solve problems such as unsatisfactory effects, and achieve the effects of simple structure, obvious effect and flexible adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

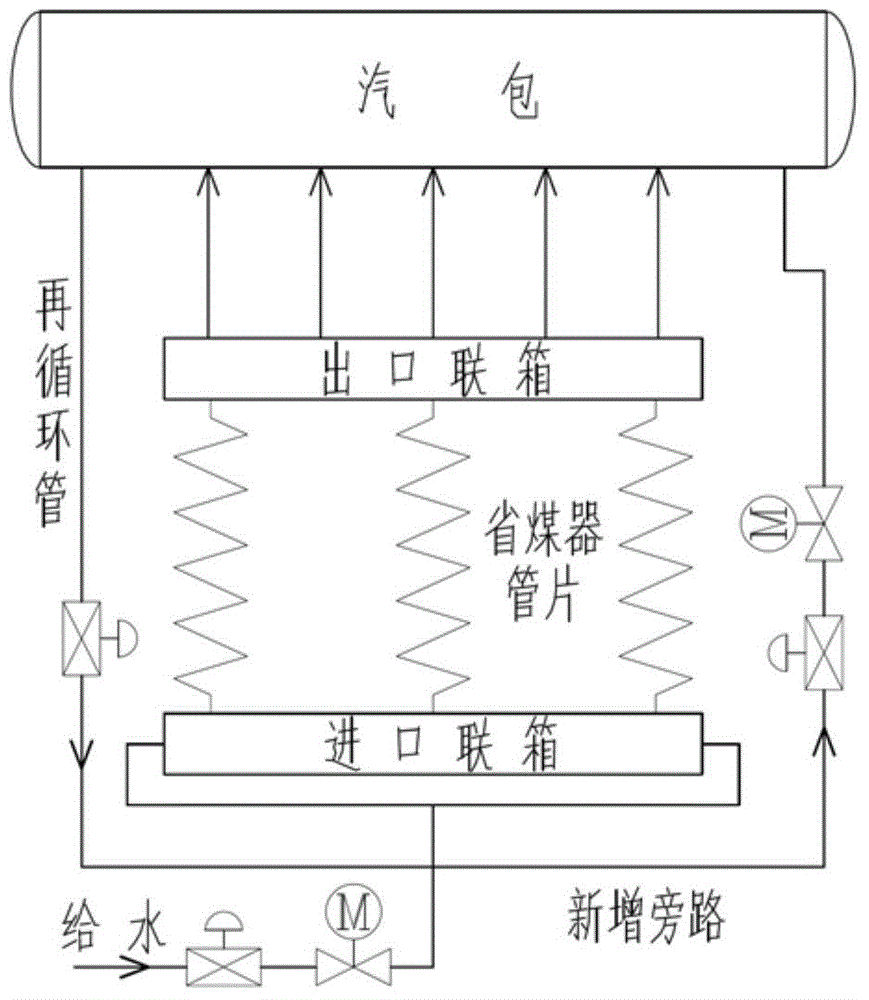

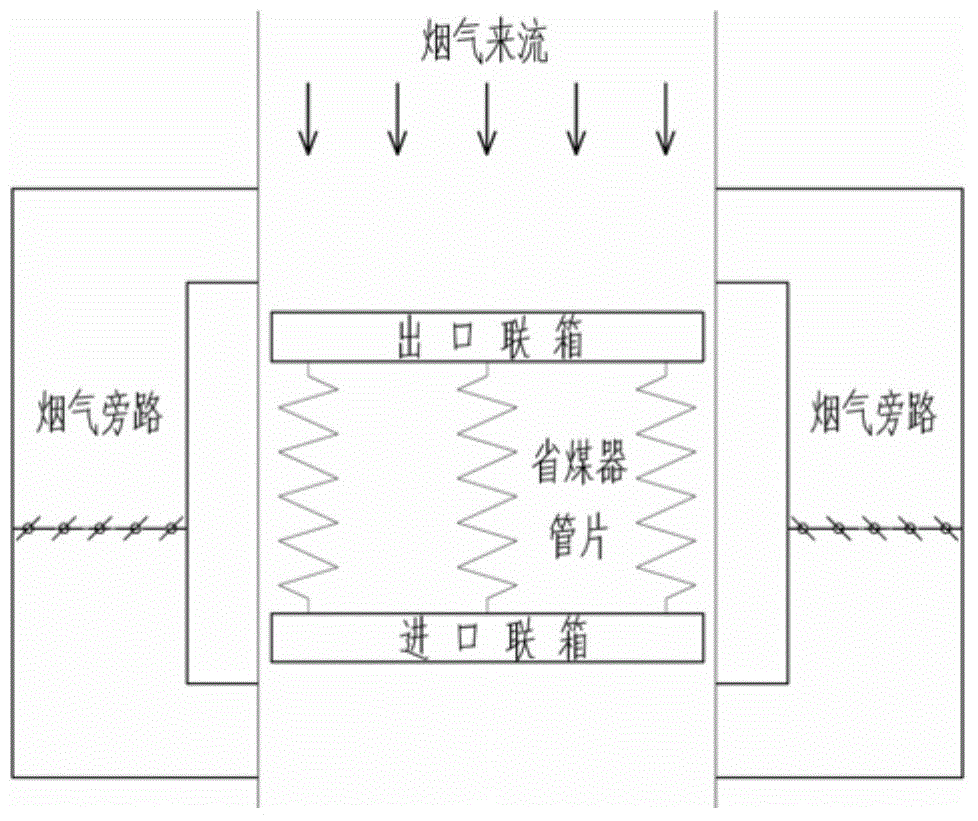

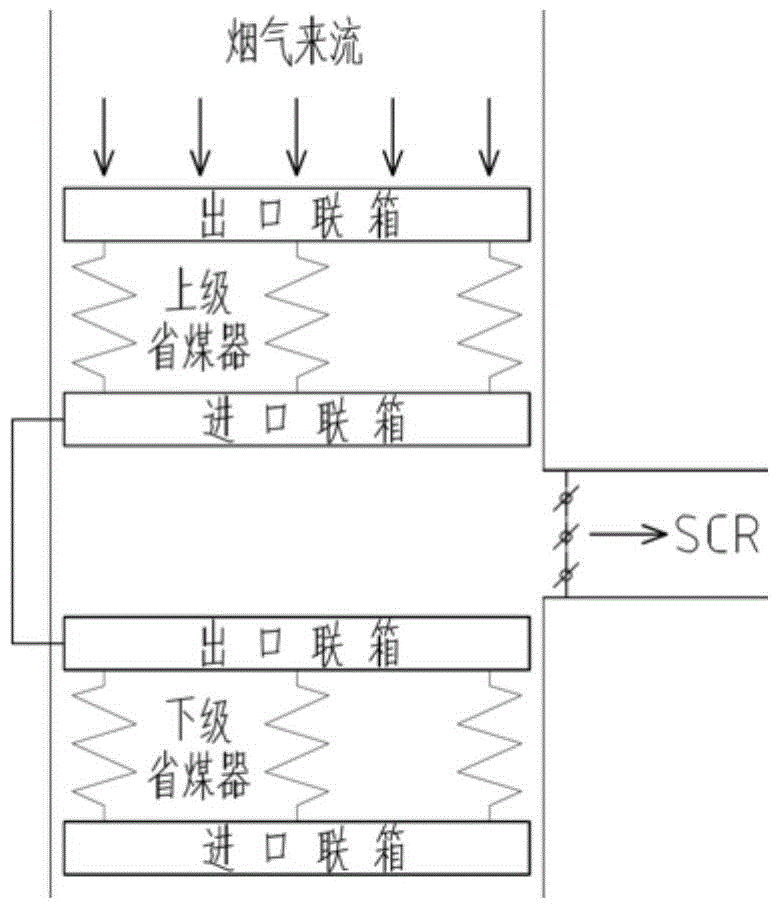

[0056] Such as Figure 4 As shown, an economizer built-in flue gas flow diversion control system includes an inlet header 3, an outlet header 4, and a plurality of serpentine pipe coils 5 arranged between the inlet header and the outlet header. The above control system also includes at least one partition 1 and a flue gas temperature regulating baffle 2, one end of the partition 1 passes through the outlet header 4 and then enters the flue between the inlet header 3 and the outlet header 4, The flue is divided, and the flue gas temperature-regulating baffle 2 is arranged on the partition 1 to block part of the flue after division.

[0057] There are two partitions 1, which divide the flue into three parts, e. The purpose of dividing into three parts is to prevent the deviation of the smoke temperature on the left and right sides. There are two flue gas temperature-regulating baffles 2, which are respectively installed on the divided flues on both sides. The flue gas temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com